Collection of questions before start - outdoor mobile and scalable

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Collection of questions before start - outdoor mobile and scalable

Hey you all,

glad to be here, and thank you for sharing here what you all do (beautiful builds here, and super interesting to read)

Long time reader, had a break, now got back into it and want to start my own build starting with one pair of DR250. Bigger thoughts in mind, but for evaluating ideas this would be my starting point. In the end the first pair will probably used as (and i really love it to have found that expression inside this formun) texas headphones, and for the front use i'll look if 280 or 200 may be a better solution; will depend on my personal listening experience on the first 2.

Somewhat skilled woodworker, long time craftsman and full workshop available.

Some long story short background: decades ago forest raves; we had a horror combination of different parts of soundsystems that just went together somehow, but is was far away from a decent sound quality. A lot changed since then, left that hobby due to life changes and a lot else, and now i want to take that build to a decent level to redo some stuff we did once, but without puking eardrums.

A few questions i want to clear before messing ideas up; condensed to one post is probably the simple way to go.

Processing side

In theory, having a 2 in 6 out controller should be sufficent for every scenario. Bi-Amping is the target, DR-Line combined with subwoofers still to choose.

6 Outs should give me the option, to have 4 of them for stereo-DR-Bi-amped, and 2 for maybe two different Sub-ranges each in mono - or is there an error to that?

How about chaining two (let's say driveracks) togehter, when for instance frontfills will be needed with their own 4 channels for bi-amping? 8 or 10 outputs gets the thing quite expensive.

Handles on DR250

As far as i understand, it shouldnt be a problem to take in sunken Handles in the sides of the throat area. Thinking about models like these: https://www.adamhall.com/shop/en/brands ... 67f3818148. Is the volume taken out of the throat area to be considered and to be replaced? As far as my understanding goes, wavelenghts shouldnt "see" that as an obstacle. The reason for these handles is the option of strapping running through, as well as the better grip.

Second handling idea in the backpanel; including connectors:

To avoid sticking out cables, i really love the idea of hiding them sort of "inside".

Following sketch for the concept: The (closed Backwall behind the cheeks) moved that far outwards, to cut two holes inside. On the inside, a sealed box against the Backpanel, with the connectors in the top/bottom part of that box. the line between the two holes as another handle, that sits flush and "hides" the connectors sort of inside the cab.

As long as cables are connected, handle is not needed. And when connected, cables just stick inside. Measurments to be taken, how far the backpanel has to be moved to fit speakon-connectors; but i think it could be worth it. Couldn't find something similar here, somebody done before on a DR?

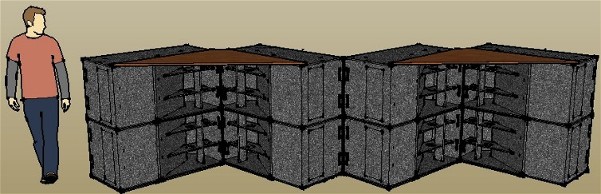

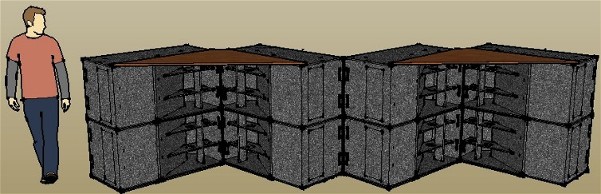

Transport

Never seen dollys around for the DRs. Has that been done? Thinking about scaleable, scaling to four per side would be neat to have a Dolly with 4 DRs on it per side. My idea goes to a groundplate where two DRs fit on, fronts facing each other, and 2 DRs high. Eventually adding a soft cover, but probably possible without. Also for storing them when not in use a neat option in my mind at least - anybody done that?

Groundstacking

As to avoid the usual stands(tripods), i thought about building "empty" boxes as a ground support when not on top of bass bins. Closed Front, just need to add some weight for stability.

How about building a 19" rack inside these "empty" boxes, to have the amping close to the sounding end and avoid endless cable lenghts? Has that been done before, and i was just too stupid to find it by the search here? Going for cheaper heavier amps could be a benefit in that case in terms of stability. To me, it doesn't seem like a bad idea; but i know i can be stupid.

Coupling V-Plate

Now to the lower end, as the main purpose will be outdoors the final rig should be good to go with two towers. For the obvious benefits, the coupling of 4 bass bins per side and an added V-plate would be the most used usecase.

Two questions on that:

First of all, the plate could be used as a groundstack for the DRs. The bracing needed for the plate anyway could be a connector to take the DRs in the same way as the ground support plate in the plans - or is there an error to that? Done before? The plate would ne to be super tight fixed on the subs to avoid any movement; but this is a situation i can think of solutions to have the desired structural stability. But will vibrations be an error? Optional "soft" stacking the DRs? So a vibration damping connection between the plate an the DRs?

Second, now it gets probably a bit wild:

In terms of efficency, i like the idea to have each frequency played by a disgn optimized for that band.

The DRs go quite low, can be tuned even lower. But how about adding a third band between the DRs and the subs (which are still to choose)?

Probably influenced by systems i've heard, but kickbins between DR and SUB doesn't seem to be automatically bad. Designs like the B115 from martin audio would be an option i had in my mind - maybe the splitting in 2 sub bands is its own discussion. Here the question regarding the coupling V-plate: How about taking a Design like the b115, and take the bottom of that cab as the plate? Could be made fitted, whatever measures and fits best. And would be a "two flies by one slap"-situation, which i really like in my mind. Everything with fixed connectors, and on top of that midbass the groundstackadapter for the DRs.

Also, the hassle you buy by adding more bands/ways to fit togehter at each event would be somewhat lower when the tower stacks together the same every event. Delay and XO could be fixed to standards and then adapted on the local situation.

Picturing such two towers makes me sorta wet in my hearing mind tbh, but it hast to be a real benefit and not just eye candy. And sure the idea is placed in my mind by other similar systems where eyecandy was a bigger factor than it should be. but when the SQ can benefit from that, i'd love that idea.

Anyone experiences on that? Midbass added inbetween, and used as a V-Plate? Ore only V-plate as groundstack for DR? Thoughts?

Edit: In addition to the idea of an amprack as a groundsupport for stacked DRs; the full tower in mind coupled together leaves a spot in the back of said tower (where the both sides of the coupled bass bins touch their tip) and there should be a somewhat integrated amprack suitable as well, or do i have an error on placing amps that close? Sure both variants in secured racks, to avoid damages. But in my mind, that should be doable and save tons of cables esp. when bi-amping.

Subwoofer to add

The V-plate-questions imply the bassbin-question; depending on added midbass or not, which would be your subwoofer of choice. Probably the "smallest" version of my usecase would be around 400 dancing ppl, music with the deep frequencies that most music does not include at all (DnB/Psytrance, each rather the experimental styles of it...), until the rather maximum part with around 1500 ppl. As always coupled in 4, The T48 would be super sufficient according to the bass bin choose-thread. On the other hand, when taking the midbass out, which model would benefit the most in the range below the midbass?

All only relevant at the end, but kind of decides if i'll build the DRs ported or not. So better ask before, maybe there are ideas floating around i couldn't find.

glad to be here, and thank you for sharing here what you all do (beautiful builds here, and super interesting to read)

Long time reader, had a break, now got back into it and want to start my own build starting with one pair of DR250. Bigger thoughts in mind, but for evaluating ideas this would be my starting point. In the end the first pair will probably used as (and i really love it to have found that expression inside this formun) texas headphones, and for the front use i'll look if 280 or 200 may be a better solution; will depend on my personal listening experience on the first 2.

Somewhat skilled woodworker, long time craftsman and full workshop available.

Some long story short background: decades ago forest raves; we had a horror combination of different parts of soundsystems that just went together somehow, but is was far away from a decent sound quality. A lot changed since then, left that hobby due to life changes and a lot else, and now i want to take that build to a decent level to redo some stuff we did once, but without puking eardrums.

A few questions i want to clear before messing ideas up; condensed to one post is probably the simple way to go.

Processing side

In theory, having a 2 in 6 out controller should be sufficent for every scenario. Bi-Amping is the target, DR-Line combined with subwoofers still to choose.

6 Outs should give me the option, to have 4 of them for stereo-DR-Bi-amped, and 2 for maybe two different Sub-ranges each in mono - or is there an error to that?

How about chaining two (let's say driveracks) togehter, when for instance frontfills will be needed with their own 4 channels for bi-amping? 8 or 10 outputs gets the thing quite expensive.

Handles on DR250

As far as i understand, it shouldnt be a problem to take in sunken Handles in the sides of the throat area. Thinking about models like these: https://www.adamhall.com/shop/en/brands ... 67f3818148. Is the volume taken out of the throat area to be considered and to be replaced? As far as my understanding goes, wavelenghts shouldnt "see" that as an obstacle. The reason for these handles is the option of strapping running through, as well as the better grip.

Second handling idea in the backpanel; including connectors:

To avoid sticking out cables, i really love the idea of hiding them sort of "inside".

Following sketch for the concept: The (closed Backwall behind the cheeks) moved that far outwards, to cut two holes inside. On the inside, a sealed box against the Backpanel, with the connectors in the top/bottom part of that box. the line between the two holes as another handle, that sits flush and "hides" the connectors sort of inside the cab.

As long as cables are connected, handle is not needed. And when connected, cables just stick inside. Measurments to be taken, how far the backpanel has to be moved to fit speakon-connectors; but i think it could be worth it. Couldn't find something similar here, somebody done before on a DR?

Transport

Never seen dollys around for the DRs. Has that been done? Thinking about scaleable, scaling to four per side would be neat to have a Dolly with 4 DRs on it per side. My idea goes to a groundplate where two DRs fit on, fronts facing each other, and 2 DRs high. Eventually adding a soft cover, but probably possible without. Also for storing them when not in use a neat option in my mind at least - anybody done that?

Groundstacking

As to avoid the usual stands(tripods), i thought about building "empty" boxes as a ground support when not on top of bass bins. Closed Front, just need to add some weight for stability.

How about building a 19" rack inside these "empty" boxes, to have the amping close to the sounding end and avoid endless cable lenghts? Has that been done before, and i was just too stupid to find it by the search here? Going for cheaper heavier amps could be a benefit in that case in terms of stability. To me, it doesn't seem like a bad idea; but i know i can be stupid.

Coupling V-Plate

Now to the lower end, as the main purpose will be outdoors the final rig should be good to go with two towers. For the obvious benefits, the coupling of 4 bass bins per side and an added V-plate would be the most used usecase.

Two questions on that:

First of all, the plate could be used as a groundstack for the DRs. The bracing needed for the plate anyway could be a connector to take the DRs in the same way as the ground support plate in the plans - or is there an error to that? Done before? The plate would ne to be super tight fixed on the subs to avoid any movement; but this is a situation i can think of solutions to have the desired structural stability. But will vibrations be an error? Optional "soft" stacking the DRs? So a vibration damping connection between the plate an the DRs?

Second, now it gets probably a bit wild:

In terms of efficency, i like the idea to have each frequency played by a disgn optimized for that band.

The DRs go quite low, can be tuned even lower. But how about adding a third band between the DRs and the subs (which are still to choose)?

Probably influenced by systems i've heard, but kickbins between DR and SUB doesn't seem to be automatically bad. Designs like the B115 from martin audio would be an option i had in my mind - maybe the splitting in 2 sub bands is its own discussion. Here the question regarding the coupling V-plate: How about taking a Design like the b115, and take the bottom of that cab as the plate? Could be made fitted, whatever measures and fits best. And would be a "two flies by one slap"-situation, which i really like in my mind. Everything with fixed connectors, and on top of that midbass the groundstackadapter for the DRs.

Also, the hassle you buy by adding more bands/ways to fit togehter at each event would be somewhat lower when the tower stacks together the same every event. Delay and XO could be fixed to standards and then adapted on the local situation.

Picturing such two towers makes me sorta wet in my hearing mind tbh, but it hast to be a real benefit and not just eye candy. And sure the idea is placed in my mind by other similar systems where eyecandy was a bigger factor than it should be. but when the SQ can benefit from that, i'd love that idea.

Anyone experiences on that? Midbass added inbetween, and used as a V-Plate? Ore only V-plate as groundstack for DR? Thoughts?

Edit: In addition to the idea of an amprack as a groundsupport for stacked DRs; the full tower in mind coupled together leaves a spot in the back of said tower (where the both sides of the coupled bass bins touch their tip) and there should be a somewhat integrated amprack suitable as well, or do i have an error on placing amps that close? Sure both variants in secured racks, to avoid damages. But in my mind, that should be doable and save tons of cables esp. when bi-amping.

Subwoofer to add

The V-plate-questions imply the bassbin-question; depending on added midbass or not, which would be your subwoofer of choice. Probably the "smallest" version of my usecase would be around 400 dancing ppl, music with the deep frequencies that most music does not include at all (DnB/Psytrance, each rather the experimental styles of it...), until the rather maximum part with around 1500 ppl. As always coupled in 4, The T48 would be super sufficient according to the bass bin choose-thread. On the other hand, when taking the midbass out, which model would benefit the most in the range below the midbass?

All only relevant at the end, but kind of decides if i'll build the DRs ported or not. So better ask before, maybe there are ideas floating around i couldn't find.

Re: Collection of questions before start - outdoor mobile and scalable

I have previously owned a single DR250. It came without handles. I installed this type: https://www.thomann.de/intl/adam_hall_34082b.htm

This does not interfere with the horn path and is a quite comfortable carry. If comfortable is at all possible with the larger DR's - they will always be somewhat peculiar to lift and carry. A DR is an unusual shape, almost cube like. It took me a while to determine a decent handle placement. I have no picture readily available so will attempt to describe in words what I did.

Carrying with the cab mouth facing my stomach if you will. Handles on the side. If you regard the side as four quarts, my handles where in the rear upper quart. Not horizontal but rather skewed. Forward edge of the handle higher than the rear edge if you will. That way the cabs were easiest to carry, with the handles perpendicular to a straight line from handle placement towards my shoulders.

Does this make sense? If not, feel free to say so and I will search my archives for a picture.

This does not interfere with the horn path and is a quite comfortable carry. If comfortable is at all possible with the larger DR's - they will always be somewhat peculiar to lift and carry. A DR is an unusual shape, almost cube like. It took me a while to determine a decent handle placement. I have no picture readily available so will attempt to describe in words what I did.

Carrying with the cab mouth facing my stomach if you will. Handles on the side. If you regard the side as four quarts, my handles where in the rear upper quart. Not horizontal but rather skewed. Forward edge of the handle higher than the rear edge if you will. That way the cabs were easiest to carry, with the handles perpendicular to a straight line from handle placement towards my shoulders.

Does this make sense? If not, feel free to say so and I will search my archives for a picture.

Re: Collection of questions before start - outdoor mobile and scalable

Connectors in the back panel: yes. But that may be simpler if you are not combining with handles. Connectors into the recessed seem deep to me.

I use Neutrik NL4MPR connectors on my cabs, not the smaller NL4MP versions. The smaller versions are OK on metal panels, they may rip out of wood when abused.

For recessed mounting I make a circular cut with a hole saw, about 5.5 to 6.0 cm diameter. Behind this I glue a smaller piece of 12mm or 15mm plywood with the small circular cutout for the connector, 2.4 or 2.5cm diameter. After painting I install the NL4MPR into this smaller piece of plywood with wood screws.

Again, if this does not make sense just let me know. I still have several cabs with connectors recessed like this. I will gladly post a picture if that helps.

I use Neutrik NL4MPR connectors on my cabs, not the smaller NL4MP versions. The smaller versions are OK on metal panels, they may rip out of wood when abused.

For recessed mounting I make a circular cut with a hole saw, about 5.5 to 6.0 cm diameter. Behind this I glue a smaller piece of 12mm or 15mm plywood with the small circular cutout for the connector, 2.4 or 2.5cm diameter. After painting I install the NL4MPR into this smaller piece of plywood with wood screws.

Again, if this does not make sense just let me know. I still have several cabs with connectors recessed like this. I will gladly post a picture if that helps.

- Bill Fitzmaurice

- Site Admin

- Posts: 29054

- Joined: Tue May 02, 2006 5:59 pm

Re: Collection of questions before start - outdoor mobile and scalable

Only if they're at least 50 feet apart. viewtopic.php?t=398Marflinger wrote: ↑Sun Dec 07, 2025 2:30 am Now to the lower end, as the main purpose will be outdoors the final rig should be good to go with two towers. For the obvious benefits, the coupling of 4 bass bins per side...

That would be a waste of cartage, amp channels and money.In terms of efficency, i like the idea to have each frequency played by a disgn optimized for that band.

The DRs go quite low, can be tuned even lower. But how about adding a third band between the DRs and the subs (which are still to choose)?

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Hey, thanks for the answers!

The other concept in my head, depending on the situation, would be a closed wall alltogether, as in the thread you linked described:

I really don't like these handles, but i've seen a lot of builds with them yeah (just without your angled orientation)

I've also seen the "just holes" in the front end of the side panels, would be my second way to go if the other volumechange would be a problem. (Holes as in the Corners of Tubas as a Handle, also in one of the build threads here)

My idea of the "angled" plugging is, that even the whole connector is flush with the surface, and only the cable is further outside. The combination with the handle was just by the idea, that when nothing connected the handle comes in handy; while during a cable connected, no more handling of the box. so a double-use of a single point if you will, and no connector showing above outer surface (and beeing pinched/ripped/whatever)...

I'll figure out the measurments needed and think about it from there, but thank you for your input.

Yeah, i've read that thread (and a lot of the others). The 15,x meters these 50 feet are will be the situation. I don't favour the dj-between-pa situation, rather towers at the front an dj in the back (FOH-position if you want). and there the towers can be further than 50 feet apart, for sure.Bill Fitzmaurice wrote: ↑Sun Dec 07, 2025 8:25 amOnly if they're at least 50 feet apart. viewtopic.php?t=398Marflinger wrote: ↑Sun Dec 07, 2025 2:30 am Now to the lower end, as the main purpose will be outdoors the final rig should be good to go with two towers. For the obvious benefits, the coupling of 4 bass bins per side...

The other concept in my head, depending on the situation, would be a closed wall alltogether, as in the thread you linked described:

Because...? I assume you mean there will be no need for the kick-addition, as the design by itself delivers that? I would be a friend of not having that, i need to build it and figure out if i need it or not i guess. The question above was rather trying to catch all possible scenarios and their lacks/benefits - even the experience from others who have done that already - if there are any.Bill Fitzmaurice wrote: ↑Sun Dec 07, 2025 8:25 amThat would be a waste of cartage, amp channels and money.In terms of efficency, i like the idea to have each frequency played by a disgn optimized for that band.

The DRs go quite low, can be tuned even lower. But how about adding a third band between the DRs and the subs (which are still to choose)?

Yep, thank you for that explanation.

I really don't like these handles, but i've seen a lot of builds with them yeah (just without your angled orientation)

I've also seen the "just holes" in the front end of the side panels, would be my second way to go if the other volumechange would be a problem. (Holes as in the Corners of Tubas as a Handle, also in one of the build threads here)

Yeah i can imagine that, thank you again for clarifying in detail. In your version, the cable still sticks in a right angle to the backpanel away from the cab, which is what i want to avoid by the rotate and hide inside the handle.

My idea of the "angled" plugging is, that even the whole connector is flush with the surface, and only the cable is further outside. The combination with the handle was just by the idea, that when nothing connected the handle comes in handy; while during a cable connected, no more handling of the box. so a double-use of a single point if you will, and no connector showing above outer surface (and beeing pinched/ripped/whatever)...

I'll figure out the measurments needed and think about it from there, but thank you for your input.

- Bill Fitzmaurice

- Site Admin

- Posts: 29054

- Joined: Tue May 02, 2006 5:59 pm

Re: Collection of questions before start - outdoor mobile and scalable

Kick bins are a relic of 1970s tech, rendered obsolete by the introduction of true subwoofers and high xmax drivers in mains. When subs and high output mains came along all users of kick bins should have retired them. But many added the subs and high output mains while keeping the kick bins, making their systems overly large and complicated. The introduction of line array technology should have made kick bins nothing more than a memory, but somehow they still hang around.

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Assuming these, which have a plate of 51mm, would end in a 60mm deep "Pocket" added to the inside of the Backpanel. Including the Lid of the pocket, assuming 12mm as the rest of the cab, would result in an overall addition of 63, lets say 65, mm (which equals to a texan slice of a cow i guess, or roughly 2,6 inches)

That addition could add the option to have corner handles around the backpanel as well, to make use of that additional space somehow, as in both standing corners the rounded cheeks offer free space by design.

Could be done smaller, adding a metal plate and the small connector like the NL4MPST; but i guess i will want the space to comfortly plug/unplug cables from there.

So, if so, i think the 2,6 inches extension would be my way to go. Seems sonewhat reasonable for me; could even add a cable channel in the back panel for keeping them flush as well by adding a vertical doubling brace centered above and below the added pocket, and slit a channel in the outer surface where the cable can sleep in...

I assume, the not needed extension and the adding of weight causes a headache in the designers head (who designed a super lightweight box compared to the power); sorry for that abuse in case that helps.

I guess i gotta hear the result without that (seemingly obsolete) addition; i am probably hanging on memorys that should have been gone for long but they still stick with me.Bill Fitzmaurice wrote: ↑Sun Dec 07, 2025 9:18 am Kick bins are a relic of 1970s tech, rendered obsolete by the introduction of true subwoofers and high xmax drivers in mains. When subs and high output mains came along all users of kick bins should have retired them. But many added the subs and high output mains while keeping the kick bins, making their systems overly large and complicated. The introduction of line array technology should have made kick bins nothing more than a memory, but somehow they still hang around.

I'll be super happy when i turn it on and do not feel the need to add something, looking forward to that

Re: Collection of questions before start - outdoor mobile and scalable

I have searched but did not find pictures of the handles in my DR. I do remember using a jig to cut identical holes on both sides for these handles. Because of the peculiar placement and angles I did not trust myself to just measure, draw, cut and end up with exact mirror image holes on either side. I'm afraid the jig may have been thrown away as well.

No worries, I see what you mean now. What you have in mind does a better job protecting the connectors from damage. There are some factory made dishes that help. They are not deep enough though to have Speakon connectors completely flush with the external cab surface. I do use these on some of my cabs:Yeah i can imagine that, thank you again for clarifying in detail. In your version, the cable still sticks in a right angle to the backpanel away from the cab, which is what i want to avoid by the rotate and hide inside the handle.

My idea of the "angled" plugging is, that even the whole connector is flush with the surface, and only the cable is further outside. The combination with the handle was just by the idea, that when nothing connected the handle comes in handy; while during a cable connected, no more handling of the box. so a double-use of a single point if you will, and no connector showing above outer surface (and beeing pinched/ripped/whatever)...

I'll figure out the measurments needed and think about it from there, but thank you for your input.

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Yes, i've seen them. But as you noted, they lack of the total flush i want to get.

The Handle in my sketching even functions as a cable-toss-prevention (However you call it in english); a way to lead the cable around the handle before plugging in, so if somehow the cable gets pulled it doesn't bring force to the connector.

Thinking about the needed addition in depth, i think the pocketed handle will be my way to go. When building, i'll post pictures and tell you all about the result and if it works as i thought. In case it sucks, i can still shorten the cab and mount a back panel without that maybe shitty idea on it.

But again, thank you for your thoughtful answers

Re: Collection of questions before start - outdoor mobile and scalable

You are welcome. I am curious to see what you come up with.

Another thought that just popped up in my head: you need easy access with your thumb to the lock on the speakon connectors. Perhaps make a test handle or recessed connector on some scrap wood. Just to get your hands on it, see how it works in different positions and angles.

Another thought that just popped up in my head: you need easy access with your thumb to the lock on the speakon connectors. Perhaps make a test handle or recessed connector on some scrap wood. Just to get your hands on it, see how it works in different positions and angles.

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Regarding the sidehandles, the model linked would take a volume out of the horn throat of 0,028 cubic feet on each side ( 0,8 liter/dm³) with a maximum lenghth of obstacle of 224mm (8,8 inch) which shouldnt be visible for the wavelengths in the throat area.Marflinger wrote: ↑Sun Dec 07, 2025 2:30 am Thinking about models like these: https://www.adamhall.com/shop/en/brands ... 67f3818148. Is the volume taken out of the throat area to be considered and to be replaced?

Am i guessing right, that when placed in the front half of the throat exit, that shouldn't change anything?

The scrapmodel with touch and try&error is a good idea, will do exactly that. Thx.AntonZ wrote: ↑Sun Dec 07, 2025 10:45 am You are welcome. I am curious to see what you come up with.

Another thought that just popped up in my head: you need easy access with your thumb to the lock on the speakon connectors. Perhaps make a test handle or recessed connector on some scrap wood. Just to get your hands on it, see how it works in different positions and angles.

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Well, as i finally got the time to import the sketchup model...well, it is already shown that way, so i assume it will be fine.Marflinger wrote: ↑Sun Dec 07, 2025 10:48 amRegarding the sidehandles, the model linked would take a volume out of the horn throat of 0,028 cubic feet on each side ( 0,8 liter/dm³) with a maximum lenghth of obstacle of 224mm (8,8 inch) which shouldnt be visible for the wavelengths in the throat area.Marflinger wrote: ↑Sun Dec 07, 2025 2:30 am Thinking about models like these: https://www.adamhall.com/shop/en/brands ... 67f3818148. Is the volume taken out of the throat area to be considered and to be replaced?

Am i guessing right, that when placed in the front half of the throat exit, that shouldn't change anything?

Shown there below the mid bracing, probably for aesthetic reasons to not show them? for the top row screws to go in the middle braces.

I'll try around what seems to be the best, but i feel free to try now without thinking about trouble that could cause.

For the backhandly i'm waiting for different connectors to arrive to test the handling, will update soon.

Guess I'll move everything related to the DR250 into the build thread soon to start, and keep the remaining questions here for later.

Last edited by Marflinger on Sun Dec 14, 2025 7:06 am, edited 1 time in total.

-

Marflinger

- Posts: 57

- Joined: Thu Dec 04, 2025 1:20 pm

- Location: Germany-Blackforest

Re: Collection of questions before start - outdoor mobile and scalable

Just for not leaving threads unanswered:Marflinger wrote: ↑Wed Dec 10, 2025 1:48 am For the backhandly i'm waiting for different connectors to arrive to test the handling, will update soon.

Playing around with a cardboardmodel first, and then getting scraps together, i figured a (super roughly) version that works for me.

(sorry for buildquality, bur for handling and testing i didn't care and just got it somehow done) For super comfort handling, the holes have a height of 900mm, the bar 20mm, so total is about 200mm. Width came out at 165mm, which is kind of the limit (i wouldn't go more narrow for two connectors) Both connectors work; i didn't have 12mm sheet scraps, and i figured to take 18mm for the bottom/top for using bigger screws for fixing them would be a good idea. even the small one is super sturdy that way. Both sunken in to be flush - when done precisly and not bye eyeguessing as in the picture that should add more stability.

Backsides could be same Material as the bent cheeks behind it in the box, maybe somehow damped. I'll take a look for that.

To be comfortable, the Handle should be doubled on the inside, as the corner handles in the plans are usually added with a quarter rounded stick, half round in this case.

Measurements will follow, depth is 60mm without the back; so 63mm in total but it will fit a bit between the cheeks.

Edit: Measurements as following:

For two connectors, the width in the back would need to be 85mm.

Bi-Amping wants to have two inputs and two outputs, i'm thinking about the need for bi-amping to be honest.

But assuming that, the total situation would be like this: and add 32,5 mm in the back.

And if not bi-amped, it can be done like this: Which would add just 9,5mm.

I'll think abpout the bi-amping, and decide before doing the backpanel. But one of these will be my way to go.

Just for getting the dimensions, this would be the backpanel in its correct size with the addition from the outside: