Hey Prior, welcome to the forum and thank you for sharing your success.

I've gotta say, your cab building experience really shows through in your execution of these cabs. Well done my friend.

And, while it's difficult to see the full venue in the photos shown, it seems you brought military grade missiles to a knife fight. Waaaay overkill for the space. If they like it loud, you sir have certainly fulfilled upon their desires and expectations.

Even though I would personally do all my cabs in Duratex, I really like the blue-ish stain, dark seams, and what looks to be a low shine/matte polyurethane topcoat. It really makes a lot of sense for the particular venue and install. Very classy. And, interesting choice to leave the top and bottom of the butt cheeks open and unfilled. I think that's a good move too, if for no other reason than simply to display and/or reveal one of the more interesting parts of the DR280 cab's design. Everything looks like a high quality build and finish, through and through. The Melded Array's look like they came out really really well too. And props for logos on the T48's. It's a nice touch that you added your own and also included the "bf" logo.

I'm sorry the thread has been mostly critical up to this point. However, it's not without reason. It's a good thing that they're low enough that no one can walk under them. Personally, if it were me, I would have squares of angle iron welded up that the bottom speaker can sit on and register into, and run 4 pieces of all-thread straight up to the ceiling into some steel 1x1 that bridges the gap between the ceilings joists. That way, the design and integrity of the speaker cab isn't responsible for any hanging load whatsoever. The cabs will be supported from below, as they were designed to be used. Plus, the angle iron, all-thread, and 1x1 can be painted to blend in more with the rest of the install. That said, ultimately, if the cabs end up falling or otherwise injuring someone due to the installation method (any installation method), the companies insurance will likely not assume liability unless the installation method has been signed off by an appropriate civil engineer. Not a huge big deal, but a possible medical and legal nightmare if there's ever an issue.

If the bass response is even enough throughout the room and the customer/venue is happy enough with the sub's arranged as is, great! However, it does appear there are placement options available that may provide an increase in performance. Again, without seeing the entire layout of the room, it's difficult to say... but, from what I

can see, there are two placement options I would recommend you/the venue try out and see if there are improvements.

Option 1, both subs together, v-plated would be best but would eat up a lot of stage floor space, so vertically stacked if there's enough vertical space to save stage floorspace, side by side if need be... aimed and firing into the back corner where the mic stands are in the photos.

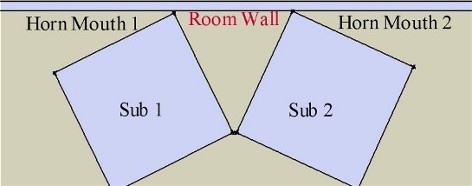

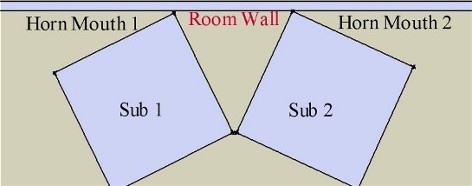

Option 2, both subs stacked vertically and wall loaded at an angle on the wall to the right or if there's room on the wall, side-by-side as shown below.

If the room is essentially twice as long as the width we can see, you may find that one sub in the corner mentioned and another kitty-corner in the back of the room may provide the best response throughout the room.

Since it's a permanent install, I think it's worth taking the time to test as many placement options as possible in order to identify the best possible response in the room. When it's good, it's really good. Like, knock your socks off, good.

BTW, how long did it take you to assemble the four DR's?