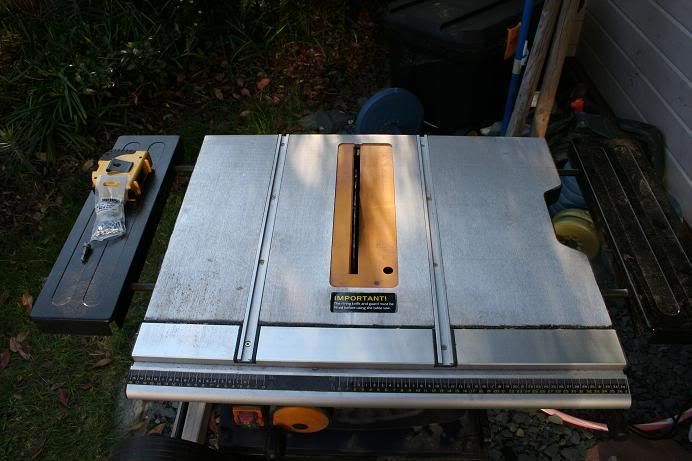

As you can see my table saw is retarded, it has very small slots in the centre of the table measuring about 5mm*4mm, not the standard ¾” slots. These are far too small for attaching a heavy piece of ply to so I tried removing the screws to remove the inserts, but they just turned in the slots…Great! So almost at a loss I decided to try hanging the runners off either side of the table instead.

So I cut some 40mm strips from ½” ply and fitted two strips together end to end, I then glued them and clamped them to the main piece. I then hung the strips tight off one side of the table and clamped the strips to the other end of the main piece. I drilled pilot holes and drove screws in the side that was still unglued. I was going to glue that side as well but I was happy with the strength and rigidity of the screws alone so I left it.

After a bit of work with the surform (or wood grater) tool I managed to get them running tight but smooth. I chose a piece of ply that was perfectly straight and laminated it with another piece to make the push bar.

There is still a bit of work to do, as the main board I used wasn’t quite big enough so I can add a bit more to it later when I get some more ply.

I am very pleased with it, I have posted this to show that even if you have a retarded table saw like me, there is still hope! My table saw cost a mere £72!!!

Right, on with the first project Omni10 KickBack Wedges! Details to follow in the coming weeks

Stu