Page 1 of 1

T24 #2

Posted: Wed Apr 20, 2016 12:25 pm

by Jake Jarmon

Checking the fence for each cut - Blade

Bottom

Top

Table Saw make this go SO much faster and all my stock is the same width! I had to bust out the wire wheel and and clean the table off.

All the panels cut out ready to mark, drill, measure, cut, glue, and clamp.

Re: T24 #2

Posted: Wed Apr 20, 2016 4:11 pm

by CoronaOperator

That is exactly what my table saw looked like after it was in a flood. I used a belt sander and some aluminum oxide sanding belts and it cleaned up pretty good, then a file for the miter slots.

Re: T24 #2

Posted: Wed Apr 20, 2016 7:51 pm

by David Raehn

You could also use electrolytic reduction to remove all the rust.

Lay a wet towel on the deck and a piece of sheet steel on top of that.

Connect a car battery charger to the assembly, negative to the deck and positive to the sheet steel.

Let it run for a day. (you may have to re-wet the towel, but make sure to turn off the charger when you do that)

Any rust will be converted to elemental iron and will brush off with a nylon bristled brush.

Take a wire wheel to it if you want it to look pretty.

Re: T24 #2

Posted: Wed Apr 20, 2016 9:54 pm

by Jake Jarmon

David Raehn wrote:You could also use electrolytic reduction to remove all the rust.

Lay a wet towel on the deck and a piece of sheet steel on top of that.

Connect a car battery charger to the assembly, negative to the deck and positive to the sheet steel.

Let it run for a day. (you may have to re-wet the towel, but make sure to turn off the charger when you do that)

Any rust will be converted to elemental iron and will brush off with a nylon bristled brush.

Take a wire wheel to it if you want it to look pretty.

Science

Re: T24 #2

Posted: Wed Apr 20, 2016 11:09 pm

by Tom Smit

Checking the fence for each cut - Blade

Did you add an extra 1/8" to account for the saw blade width (kerf)?

Re: T24 #2

Posted: Wed May 04, 2016 11:19 pm

by Jake Jarmon

Yes, I am dead reckoning to the inside edge of the blade. It has been a very busy few weeks. Got a new job, ran sound and lights at a large theater for a school musical with mariachi. PA was horribly set up and optimized although

http://www.sweetwater.com/store/detail/GL2800-848 was fun to mix on. I also rebuilt my dads old Yamaha Club S115 IVs. Anyways I finished T24 #2 and here are some pics!

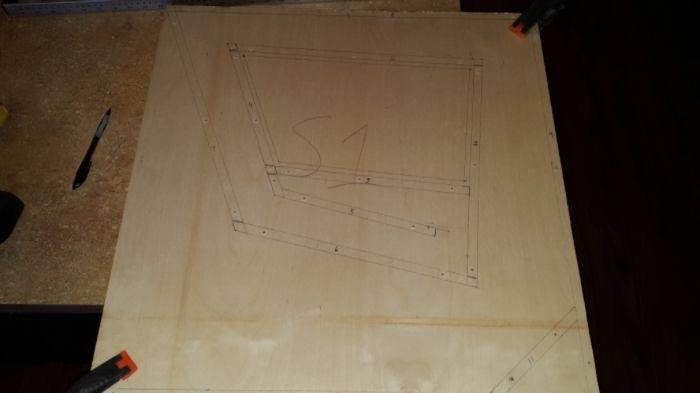

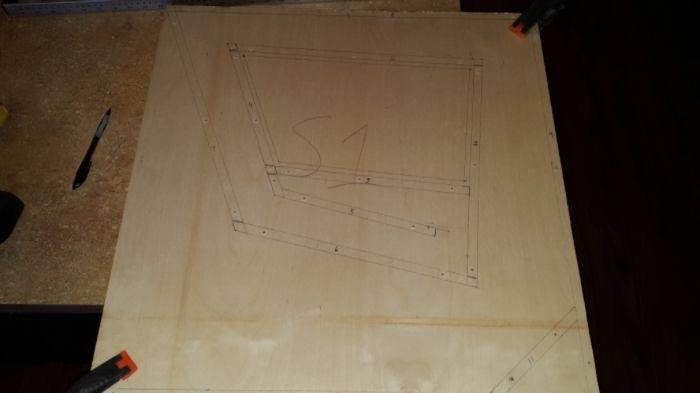

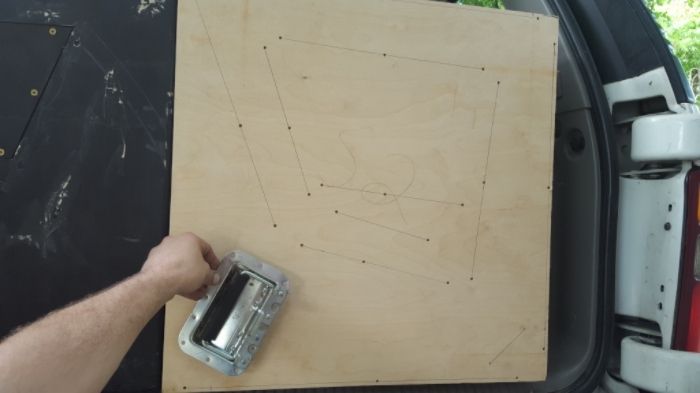

Marked and drilled

End of day 1

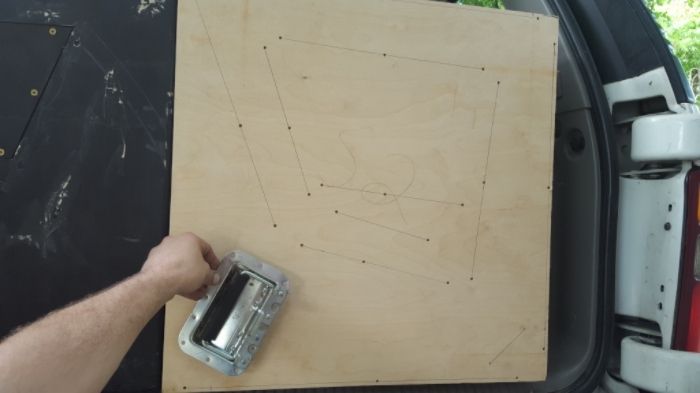

Cab 2 sealed. Forgot to take pics. Ohhhhh man just burly fit

Thinking about putting these flush mount handles here. Any thoughts?

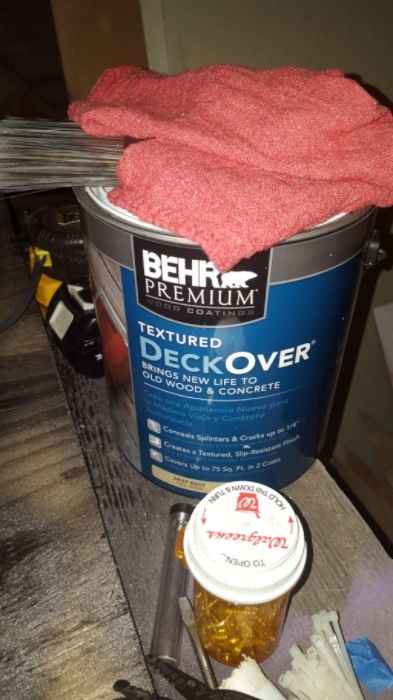

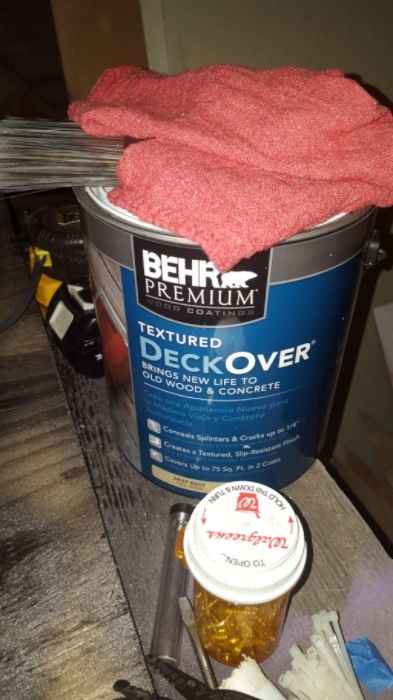

This stuff is amazing and it's only $36 a gallon @ The Depot of Home

. I tinted it slate, the darkest they had.

One down and she approves.

At this point I got side tracked and started working on the S115IVs. They were stored upside down and the floor got wet. The tops started to rot off but they have a lot of sentimental value so I couldn't bear to break em down for parts.

PAINT!!!

Two rebuilt sounding good

Two painted with one coat of textured deckover. I barely put a dent in the gallon. Time to make my ears bleed.

Somebody forgot to load the Vplate

Small choir concert at my wifes school.

Re: T24 #2

Posted: Thu May 05, 2016 12:04 am

by CoronaOperator

Please tell me you played this to 50v with the hatch down

!

Re: T24 #2

Posted: Thu May 05, 2016 8:22 am

by J_Dunavin

Not to 50v only 35v.

At 50v the BP102 goes poof!

Re: T24 #2

Posted: Thu May 05, 2016 8:24 am

by CoronaOperator

J_Dunavin wrote:Not to 50v only 35v.

At 50v the BP102 goes poof!

Ooops, my bad.

Re: T24 #2

Posted: Thu May 05, 2016 9:19 am

by Jake Jarmon

The amp is only capable of 37-40v but the door speakers eat your face before ~ 25v. Doors speakers are running off the head unit. I successfully extended a crack in my windshield this morning on my way to work jamming some Lonely Island. Whoops...

Re: T24 #2

Posted: Thu May 05, 2016 10:27 am

by Tom Smit

[/url]

Small choir concert at my wifes school.