First a few pics.

The cabs:

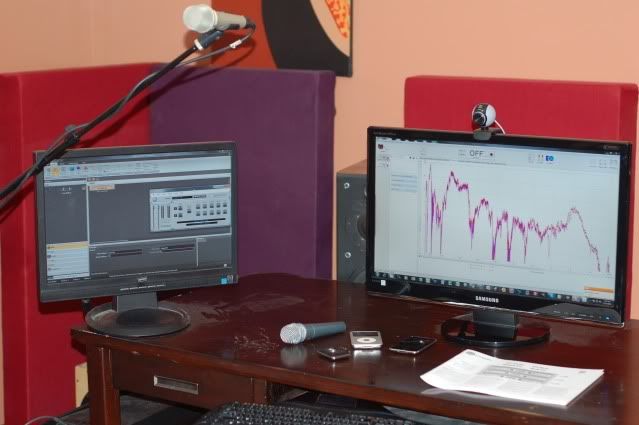

The testing set up:

Then this happened. I foolishly was carrying the dr200 in the stand and stepped up a 2 ft step onto my patio and kerplat! the dr200 fell right on his face. I made a seasonally appropriate 'fall' joke then checked the damage. Surprisingly just a corner got a little dented and the tweeter array cracked. Probably fell about 7 or 8 feet. Good thing it is made of fiberglass and not yet finished, otherwise I would have been pissed!

You can't really evaluate it after that, but I tried anyway.

I set up a measurement mic and set the xover in the xti200 for the T39 for 24dB/oct LR at 40 hz and 24 db/oct LR at 100 Hz. The dr200 was set at hp of 100 Hz. I kept the levels moderate, but loud enough for a party. Outside, the DR200 was outrunning the T39 handily. Inside the dr200 was louder than I would ever want it, so the T39 kept up fine. After setting the xover and matching the level outside, i had planned to take some measurements, but ended up just putting some music on and listening. It sounded too good to play pink noise !

I know this has been said before, but the T39/dr200 combo sounds nice. Very nice. Outside it really opens up. It just has a clarity that is very open. I put some eq cuts at around 10 k and 16 k to tame the top end a bit. I wouldn't say that the sound is 'hifi' but it is not typical pa (and by that I mean overly bright). When I have the chance I will take some more measurements and eq it a bit more. I'll wait until I have another one built to really give it a thorough review though, consider this just a teaser. I have a pair of epoxy/fiberglass oTop 12"s in the works too.

Robby