Soldering help

Soldering help

The plans have been very thorough so far and I'm just about finished with my 2x10 O12s! I just want to make sure I don't screw up probably the most important part - connecting the crossover components. I have never soldered before, I've watched some youtube instructional videos since and I think I can do it, but the plans seem to very vague on what to use. They say to use a 50 watt iron, and electrical solder, but what size? My local store probably has 30 different kinds, it was very confusing and I just want to make sure I'm getting the right stuff. Also, I know spade lugs are advised against, but how bad are they really? Would it be ok for me to use those for the drivers just to be certain I'm not killing the drivers before I even get to hear them? Also, how do you know when you've adaquately heated the components and wires? Feels like a guessing game right now. Any reccomendations for a newbie iron would be nice also. This is probably the only time I'll be using it. Thanks

Re: Soldering help

Are you considering buying a soldering gun just for the crossover?? I'd advise against it. Why do I think so?

Out of all the guns I've ever bought / used over the years, the only one that was worth a darn was an ancient Craftsman my Dad bought back in the 70's. Every one (even the Weller and Craftsman guns) since then has failed, some times quickly, others fail slowly, losing heat as the coils as the transformers give out. Most only have one or two settings.."not hot enough, and not-working". When do they fail? When you use them, and that of course is when you tend to need them. There's not much to the guts of a soldering gun, you'd think they could build them better some how.

The only reliable electric soldering products I've used since have been the pen and station units, and they tend to cater to bench / lab work. They're not something you lug up to the roof, down in the basement, or use out side in the car. You can of course, but they're just not designed for it.

So this is what I came up with: http://www.amazon.com/Weller-P2KC-Profe ... B000WOHSHM

It's butane operated. It's a pen so it's easy enough to use at the bench / rework. It's hot enough to use outdoors in the cold, or (god forsake) on plumbing. It's cordless and it's reliable. I've gone through one can of butane in the last three years. It heats up fast, is adjustable, keeps it heat, and quite frankly just works all-the-time. You can even use it on heat-shrink tubing or to light a cigar. You don't need to go Weller, other butane pens work just as well. But that's my $0.02 I like buying tools that are multi-functional.

As far as adequate heat? Just enough to get the solder to melt and flow into the joint and then count, "one-potato". Practice beforehand once you get the tools.

Type of solder? Well, there's 60/40 for electrical work which has lead in it. Then there's silver solder that has a higher melting temp for plumbing.

You might think this will be the only time you use it, but once you've got your paws on one, you'll find yourself fixing things with it. It'll pay for itself, the first couple repairs you make.

Cheers,

Radian

Out of all the guns I've ever bought / used over the years, the only one that was worth a darn was an ancient Craftsman my Dad bought back in the 70's. Every one (even the Weller and Craftsman guns) since then has failed, some times quickly, others fail slowly, losing heat as the coils as the transformers give out. Most only have one or two settings.."not hot enough, and not-working". When do they fail? When you use them, and that of course is when you tend to need them. There's not much to the guts of a soldering gun, you'd think they could build them better some how.

The only reliable electric soldering products I've used since have been the pen and station units, and they tend to cater to bench / lab work. They're not something you lug up to the roof, down in the basement, or use out side in the car. You can of course, but they're just not designed for it.

So this is what I came up with: http://www.amazon.com/Weller-P2KC-Profe ... B000WOHSHM

It's butane operated. It's a pen so it's easy enough to use at the bench / rework. It's hot enough to use outdoors in the cold, or (god forsake) on plumbing. It's cordless and it's reliable. I've gone through one can of butane in the last three years. It heats up fast, is adjustable, keeps it heat, and quite frankly just works all-the-time. You can even use it on heat-shrink tubing or to light a cigar. You don't need to go Weller, other butane pens work just as well. But that's my $0.02 I like buying tools that are multi-functional.

As far as adequate heat? Just enough to get the solder to melt and flow into the joint and then count, "one-potato". Practice beforehand once you get the tools.

Type of solder? Well, there's 60/40 for electrical work which has lead in it. Then there's silver solder that has a higher melting temp for plumbing.

You might think this will be the only time you use it, but once you've got your paws on one, you'll find yourself fixing things with it. It'll pay for itself, the first couple repairs you make.

Cheers,

Radian

Good food, good people, good times.

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

Re: Soldering help

You need rosin-core solder......the thinner size being easier to get flowing.

The above post has good advice too (even though I can get by with a gun).

The above post has good advice too (even though I can get by with a gun).

TomS

Re: Soldering help

Thanks for the advice thus far. I won't be getting a gun as this is the only time I'll be soldering anything. Radioshack has a 45 watt iron that's all of 20 dollars, any ideas on how this will fair me? I'm glad I at least know what to look for as far as solder goes.

Re: Soldering help

i use a cheap Weller soldering pen and it works fine, just takes some time to heat up.

tip: when soldering small parts/pieces of wire, i prepare all the pieces by heating up each piece on its own and getting solder on each piece first. then i can can touch the two pieces together, touch them with the iron and they are together instantly.

tip: when soldering small parts/pieces of wire, i prepare all the pieces by heating up each piece on its own and getting solder on each piece first. then i can can touch the two pieces together, touch them with the iron and they are together instantly.

Jack 112 deltalite 2512 x2

in progress: 24" T39 3012LF loaded, for bass guitar and PA use

in progress: 24" T39 3012LF loaded, for bass guitar and PA use

Re: Soldering help

If you are certain that this will be the only time you'll solder something, have you considered borrowing a gun / pen from someone or family nearby? High school craft / tech departments and college engineering departments always have this stuff on hand. If you live in a metro area, you could look around for a "tool library". They are usually community sponsored DIY tool rental depots.

$20 is $20...If you're only going spend it once for a tool you only intend to use once, why not buy a completed crossover from Leland?

$20 is $20...If you're only going spend it once for a tool you only intend to use once, why not buy a completed crossover from Leland?

Good food, good people, good times.

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

Re: Soldering help

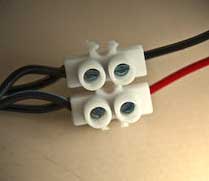

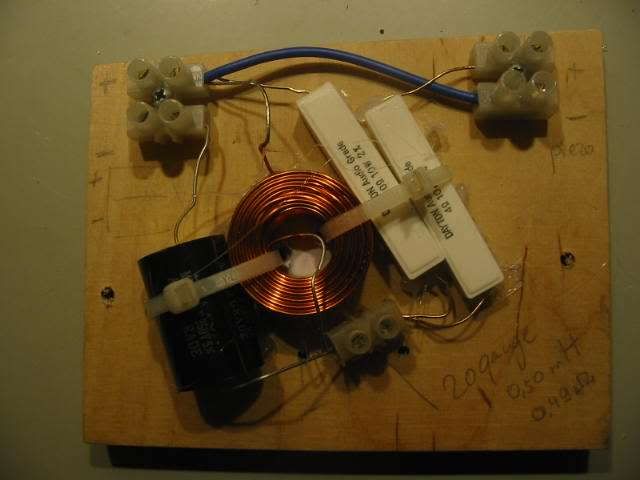

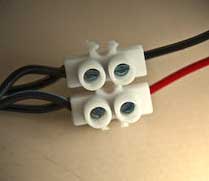

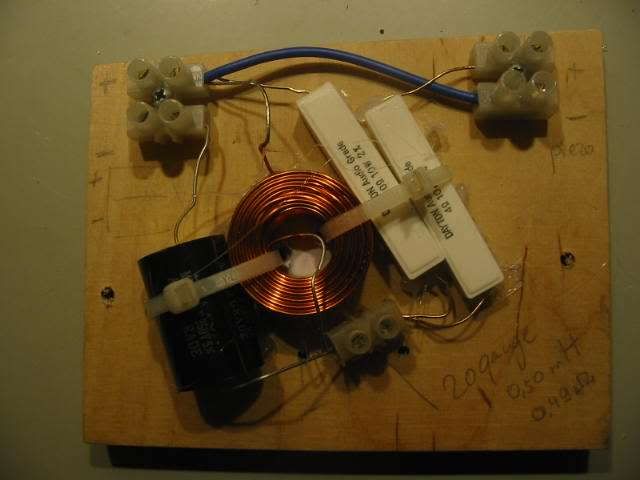

Don't you have these in the US?

I don't know what they are called in english, but these are readily available in all DIY shops here. Can be used to put your crossover together without soldering. Here's the high pass section in one of my crossovers:

I don't know what they are called in english, but these are readily available in all DIY shops here. Can be used to put your crossover together without soldering. Here's the high pass section in one of my crossovers:

Re: Soldering help

Those are called barrier strips over here.

Good food, good people, good times.

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

4 - AT

1 - TT

1 - THT Slim

2 - SLA Pro 4x6 Alphalite

1 - T18

Re: Soldering help

We do! I was considering them but I thought they provided an inferior connection. How's yours working out for you?AntonZ wrote:Don't you have these in the US?

Re: Soldering help

Buy a solder station type iron from Grainger or another industrial supplier.Preferably one with variable heat like this one. Should last quite awhile and cover most of your soldering needs. You wont silver solder with it as they usually require above 1200 degrees to get to the melting point.

http://www.grainger.com/Grainger/WELLER ... Pid=search

I prefer a Rosin Core 97%Tin 3%Copper solder for crossover and electrical (not electronic).

A Tin/Silver/Copper mix is good as well.The short plastic state is great for xlr connectors!

For finer electronics work such as circuit cards etc. I like the Rosin Core 63Tin/37lead mixes as this eliminates the plastic state when heating and cooling. On circuit cards this results in faster work and less chance to be able to move components around. 60/40s are good if you need more positioning time.

For high temp lighting I use silver solder because regular solder will melt from the pin temps created in the bases of most PAR style cans.

For silver soldering I use a Water welder which is an Oxy-Hydrogen flame through a methanol booster that burns up to 5000 degrees but is very tiny.Very effective and precise unit to work with but a tad costly.

http://www.sra-solder.com/ww.htm

When soldering any components tinning is a good practice.Another good practice is making sure both pieces are in good contact with each other as cold joints can lead to serious problems down the road. Practice makes perfect. Nothing wrong with a few practice attempts.

http://www.grainger.com/Grainger/WELLER ... Pid=search

I prefer a Rosin Core 97%Tin 3%Copper solder for crossover and electrical (not electronic).

A Tin/Silver/Copper mix is good as well.The short plastic state is great for xlr connectors!

For finer electronics work such as circuit cards etc. I like the Rosin Core 63Tin/37lead mixes as this eliminates the plastic state when heating and cooling. On circuit cards this results in faster work and less chance to be able to move components around. 60/40s are good if you need more positioning time.

For high temp lighting I use silver solder because regular solder will melt from the pin temps created in the bases of most PAR style cans.

For silver soldering I use a Water welder which is an Oxy-Hydrogen flame through a methanol booster that burns up to 5000 degrees but is very tiny.Very effective and precise unit to work with but a tad costly.

http://www.sra-solder.com/ww.htm

When soldering any components tinning is a good practice.Another good practice is making sure both pieces are in good contact with each other as cold joints can lead to serious problems down the road. Practice makes perfect. Nothing wrong with a few practice attempts.

Ever since I replaced sex with food I cant even get into my own pants!

Re: Soldering help

I have a $20 RS iron and it's usable, but I don't like to use it. The heat seems to vary (it cools as you use it, then heats up between). It did the job for a long time, and if you're only going to use it occasionally, I don't see why not.

I happen to be one of those people who does solder somewhat often, so I see the value of a temperature controlled unit. If you're going to solder more in the future, $20 on the RS model is a waste, but if you're not, then whatever you spend on a more expensive model is likewise a waste. FWIW, I use a Hakko 936.

As for solder, I'd second the 63/37 rosin core suggestion. I think it makes it easier to avoid cold solder joints. .031" or .020" will work for most tasks.

I happen to be one of those people who does solder somewhat often, so I see the value of a temperature controlled unit. If you're going to solder more in the future, $20 on the RS model is a waste, but if you're not, then whatever you spend on a more expensive model is likewise a waste. FWIW, I use a Hakko 936.

As for solder, I'd second the 63/37 rosin core suggestion. I think it makes it easier to avoid cold solder joints. .031" or .020" will work for most tasks.

Re: Soldering help

Gack!!! sure is costly!!! But I can see the use for those who make a living with electrical devices.Ron K wrote:For silver soldering I use a Water welder which is an Oxy-Hydrogen flame through a methanol booster that burns up to 5000 degrees but is very tiny.Very effective and precise unit to work with but a tad costly.

http://www.sra-solder.com/ww.htm

TomS

Re: Soldering help

I know . I didn't exactly pay for mine. I sort of rescued it.Company bought it for silver soldering needs on some injection molding systems.In time those cal-rod heaters were replaced with ones where the electrical tab didn't break off so easily so they really no longer needed it. Someone had used it (not knowing exactly how) and ran the unit out of water and warped the electrode coil inside the tank. They were not interested in repairing it because they really didn't need it so I offered to give it a good home.Tom Smit wrote:Gack!!! sure is costly!!! But I can see the use for those who make a living with electrical devices.Ron K wrote:For silver soldering I use a Water welder which is an Oxy-Hydrogen flame through a methanol booster that burns up to 5000 degrees but is very tiny.Very effective and precise unit to work with but a tad costly.

http://www.sra-solder.com/ww.htm

I ordered the part and fixed it up and the rest is history! They really work well for precision silver soldering.I actually use it quite a bit. Par cans,car audio connections,foggers/hazers, anything with heater elements etc., RC aircraft servo extension leads (especially the bigger ones) because they are prone to cracking from the vibrations, smoke muffler or regular muffler extensions, tuned pipe extensions.....stuff like that!

Ever since I replaced sex with food I cant even get into my own pants!

Re: Soldering help

Very good, Ron! I'm glad that it was not just thrown out then, but rather, it got recycled.

Did you mean car exhaust?

Did you mean car exhaust?

TomS

Re: Soldering help

No. Car and bike stuff would probably be done with an oxy-acetylene torch with a brazing tip.

On larger gas operated RC airplanes some of the mufflers are made from Tin similar to lawnmower or weed whacker motors. It's common to take some copper and coil it inside the muffler box then braze/silver solder that coil into place along with adding the fittings etc. I've probably made 10 or more for friends of mine doing large scale RC. Were talking 1/5th-1/4 scale type aircraft. These are not small.

Same goes with servo extension leads. You can solder them with regular solder but trust me if the vibrations from say a 1/5th scale Extra 300 cause one of the wing aileron servos to stop in the middle of a snap-roll on take-off you can be assured that the end result will be a bag of balsa and fibreglass with a motor hanging on the end and a very upset individual who spent countless hours building this only to have it destroyed is less then 30 seconds!

Basically they are for smaller silver brazing type jobs where a small torch flame is needed.These flames are less then 1 inch long depending on the gauge tip you use. Gives you the heat necessary for high temp (5000 degrees) in a very small flame so you can do very intricate work. they are used a lot by jewelers for repairs and even new pieces.

On larger gas operated RC airplanes some of the mufflers are made from Tin similar to lawnmower or weed whacker motors. It's common to take some copper and coil it inside the muffler box then braze/silver solder that coil into place along with adding the fittings etc. I've probably made 10 or more for friends of mine doing large scale RC. Were talking 1/5th-1/4 scale type aircraft. These are not small.

Same goes with servo extension leads. You can solder them with regular solder but trust me if the vibrations from say a 1/5th scale Extra 300 cause one of the wing aileron servos to stop in the middle of a snap-roll on take-off you can be assured that the end result will be a bag of balsa and fibreglass with a motor hanging on the end and a very upset individual who spent countless hours building this only to have it destroyed is less then 30 seconds!

Basically they are for smaller silver brazing type jobs where a small torch flame is needed.These flames are less then 1 inch long depending on the gauge tip you use. Gives you the heat necessary for high temp (5000 degrees) in a very small flame so you can do very intricate work. they are used a lot by jewelers for repairs and even new pieces.

Ever since I replaced sex with food I cant even get into my own pants!