myn's Tuba HT Build Thread

Re: myn's Tuba HT Build Thread

Check HD or Lowe's for the tubing. If they don't have it, find an aquarium store/pet shop that specializes in aquariums. They will have plenty of the tubing, and usually cheaper than HD/Lowe's.

30V into a single THT will mean you have to high-pass, as 19Hz is an excursion maximum, over 20mm at 30V. 25Hz excursion at 30V is 8mm, though. This is according to hornresp. Oh yeah, you'll be getting close to or above 130dB at 25Hz with 30V at 1m, not counting room gain.

My THT never sees even 15V, and that's only below 25Hz. Above 25Hz, less than 10V.

30V into a single THT will mean you have to high-pass, as 19Hz is an excursion maximum, over 20mm at 30V. 25Hz excursion at 30V is 8mm, though. This is according to hornresp. Oh yeah, you'll be getting close to or above 130dB at 25Hz with 30V at 1m, not counting room gain.

My THT never sees even 15V, and that's only below 25Hz. Above 25Hz, less than 10V.

Re: myn's Tuba HT Build Thread

Thumb drive?

Got some nice silicone tubing from PetSmart on the way home. $2.49. Thanks for the suggestion on the Pet store.

Heading down to see if I can pinpoint the rushing air (leaks) issue.

Got some nice silicone tubing from PetSmart on the way home. $2.49. Thanks for the suggestion on the Pet store.

Heading down to see if I can pinpoint the rushing air (leaks) issue.

Re: myn's Tuba HT Build Thread

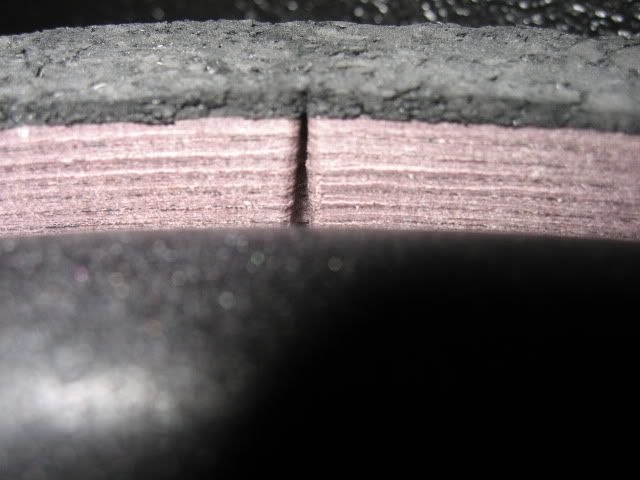

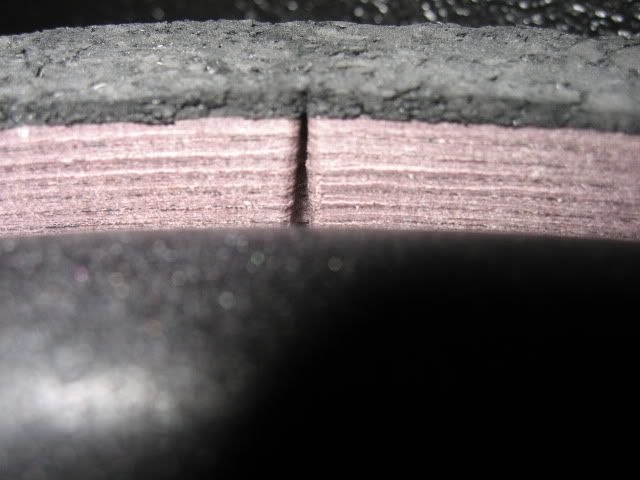

Welp, that silicone tubing definitely worked great. I was able to target the leaks really quickly. The gasket is made up of 4 pieces each of which a split between. In all 4 locations where their is a vertical split between the quartered sections of gasket there is a leak. Some leaking a little more than others.

I am considering this a major design flaw on Eminence's part. I also think anyone who has used this DVC driver in their horns should double check for leaks as this doesn't appear to be a one off issue.

I tried adding some modeling clay to the outside of the frame where one the slits was that had the most air leaking and it reduced it a bit but there still was a tiny bit of air leaking. With the driver now out of the enclosure I'd like to fill the gaps somehow, perhaps from the inside perimeter of the gasket at the source. I was thinking crazy glue/CA Glue. I have some good thick stuff designed for reconing speakers? Anyone else got some ideas? Epoxy?

Check the pics below. It's actually pretty obvious.

I am considering this a major design flaw on Eminence's part. I also think anyone who has used this DVC driver in their horns should double check for leaks as this doesn't appear to be a one off issue.

I tried adding some modeling clay to the outside of the frame where one the slits was that had the most air leaking and it reduced it a bit but there still was a tiny bit of air leaking. With the driver now out of the enclosure I'd like to fill the gaps somehow, perhaps from the inside perimeter of the gasket at the source. I was thinking crazy glue/CA Glue. I have some good thick stuff designed for reconing speakers? Anyone else got some ideas? Epoxy?

Check the pics below. It's actually pretty obvious.

- Bill Fitzmaurice

- Site Admin

- Posts: 29056

- Joined: Tue May 02, 2006 5:59 pm

Re: myn's Tuba HT Build Thread

That gasket arrangement isn't unique to Eminence. If the gaps appear large fill them with hot-melt glue, it's a 30 second fix once the gun heats up.

Re: myn's Tuba HT Build Thread

Applying Hot-melt glue to the inside perimeter? Hot-melt glue that close to the foam surround scares me. If I apply it to the outside perimeter will it be able to fill it properly? I suspect I will see the same results as when I used the molding clay on the outside perimeter, still minor leaks.Bill Fitzmaurice wrote:That gasket arrangement isn't unique to Eminence. If the gaps appear large fill them with hot-melt glue, it's a 30 second fix once the gun heats up.

Re: myn's Tuba HT Build Thread

If you are afraid of using hot-melt near the foam surround (I sure as hell would be) use a silicone sealant, especially if there will be ANY compression of that felt-like material. I like using the clear stuff; comes out white out of the tube, as it vulcanizes, turns clear.

I use Dap's Kwik Seal Plus kitchen and bath silicone caulk/adhesive, load it into a small syringe (not a medical syringe, but one like this):

http://www.overbyinkjetsolutions.com/re ... log/86.jpg

That way you have much more control over where the caulk goes. Let cure, let 'er rip. If you still have leaks, use the caulk once more while the driver is in place to stop the leank for good. Same thing, let the caulk cure before stressing it.

Oh, try veterinary or dental supply houses for syringes like those, or fiberglass supply houses (where I got mine).

Another version that looks promising:

http://ecx.images-amazon.com/images/I/2 ... AA280_.jpg

JSS

I use Dap's Kwik Seal Plus kitchen and bath silicone caulk/adhesive, load it into a small syringe (not a medical syringe, but one like this):

http://www.overbyinkjetsolutions.com/re ... log/86.jpg

That way you have much more control over where the caulk goes. Let cure, let 'er rip. If you still have leaks, use the caulk once more while the driver is in place to stop the leank for good. Same thing, let the caulk cure before stressing it.

Oh, try veterinary or dental supply houses for syringes like those, or fiberglass supply houses (where I got mine).

Another version that looks promising:

http://ecx.images-amazon.com/images/I/2 ... AA280_.jpg

JSS

Re: myn's Tuba HT Build Thread

Use Elmer's rubber cement. Easy to apply, dries overnight, and no stinky fumes. Available at K-Mart, Wal-Mart, or any store that has school supplies. Also great for sealing the backs of piezo arrays.

I know money often seals the deal, but seriously, quality is an investment, not an expense... Grant Bunter

Accept the fact that airtight and well-braced are more important than pretty on the inside. Bill Fitzmaurice

Accept the fact that airtight and well-braced are more important than pretty on the inside. Bill Fitzmaurice

Re: myn's Tuba HT Build Thread

I've heard many people say that the vapors that silicone makes from curing will eat away at foam surrounds.maxmercy wrote:If you are afraid of using hot-melt near the foam surround (I sure as hell would be) use a silicone sealant, especially if there will be ANY compression of that felt-like material. I like using the clear stuff; comes out white out of the tube, as it vulcanizes, turns clear.

I use Dap's Kwik Seal Plus kitchen and bath silicone caulk/adhesive, load it into a small syringe (not a medical syringe, but one like this):

http://www.overbyinkjetsolutions.com/re ... log/86.jpg

That way you have much more control over where the caulk goes. Let cure, let 'er rip. If you still have leaks, use the caulk once more while the driver is in place to stop the leank for good. Same thing, let the caulk cure before stressing it.

Oh, try veterinary or dental supply houses for syringes like those, or fiberglass supply houses (where I got mine).

Another version that looks promising:

http://ecx.images-amazon.com/images/I/2 ... AA280_.jpg

JSS

I've used silicone as a sealer in past enclosures and never had a problem but I waited days before putting in the speaker driver.

If I put the silicone directly onto the inside vertical gasket it will most likely be touching the edge of the foam surround that gets binded underneath the gasket.

Is this silicone issue a myth or should I not use silicone?

More info here: http://www.avsforum.com/avs-vb/showthread.php?t=789138

Re: myn's Tuba HT Build Thread

No....it is not a myth. Depending on the type of RTV, it can outgas ammonia, acetic acid (vinegar), alcohols, or cyanates (cyanate outgassing RTV is probabaly not available in hardware stores). Polyurethane foam (If that's what the DVC surround is made of) is cyanate based, IIRC, like all urethanes.....

Hmmm....to tell the truth, not sure what type I used (my nose says ammonia or acetic acid outgassing), but I have had no problems with corrosion or foam deterioration in my SLAs....but the RTV cured for days before I had them completely finished, and they are ported boxes.....

That rubber cement idea is sounding better....or just using RTV on the outside area of the gasket, testing for leaks, then take the cover off/driver out and let it fully cure before re-installing....Or be really careful with some of the more flexible type of hotglue as Bill recommended, no outgassing there.

JSS

Hmmm....to tell the truth, not sure what type I used (my nose says ammonia or acetic acid outgassing), but I have had no problems with corrosion or foam deterioration in my SLAs....but the RTV cured for days before I had them completely finished, and they are ported boxes.....

That rubber cement idea is sounding better....or just using RTV on the outside area of the gasket, testing for leaks, then take the cover off/driver out and let it fully cure before re-installing....Or be really careful with some of the more flexible type of hotglue as Bill recommended, no outgassing there.

JSS

Re: myn's Tuba HT Build Thread

Looks like GE Silicone II outgases ammonia vapors instead of acetic acid. Will that work with polyurethane foam surround?

Or how about Latex caulk?

The contact cement I am used to using is very thin and seems to "rub off" easily. Will contact cement bind to the gasket material?

Or how about Latex caulk?

The contact cement I am used to using is very thin and seems to "rub off" easily. Will contact cement bind to the gasket material?

-

wallywally

- Posts: 673

- Joined: Thu Jun 21, 2007 7:20 pm

- Location: Mount Airy, MD

- Contact:

Re: myn's Tuba HT Build Thread

I use latex caulk with great success.

Builds:

T-39

DR 280

Wedgehorn 8

Omni 12

SLA

TAT

TLAH experimental

T-39

DR 280

Wedgehorn 8

Omni 12

SLA

TAT

TLAH experimental

Re: myn's Tuba HT Build Thread

I think you'll be fine with either. If ammonia dissolved polyurethane foam, I'd be in trouble, as I've used Windex many times around poly foams...

JSS

JSS

Re: myn's Tuba HT Build Thread

[== 10/16/2009 ==]

So before jumping into the latex caulk, I thought there may be a better substrate that can seep into the gaskets vertical gap crevice better. After doing some more researching tonight about common adhesives people use to recone and refoam their speakers 2 separate adhesives stood out.

Aleen's Tacky Glue and Weldbond.

Most of the discussion I have seen on these 2 glues is that they are flexible when dry, durable, Have the consistency of white glue and don't hurt foam surrounds.

So off I went to Blicks Arts store and bought Weldbond, Than over to JoAnns for Aleen's Tacky Glue. Super cheap, both under $4.

Weldbond is actually used on the space shuttle and people claim it adhere's to just about everything. Aleen's tacky glue is often used to repair minor punctures to foam surrounds and remains flexible and strong.

For my primative test I put many dabs of glue on pieces of scrap wood. I put a rag ontop of glue dabs which will be my test for adhesion to a flexible material.

Tomorrow I will see if the glue is flexible and test how it adhered to the cloth. The Titebond is in the pic for nothing more than the control for this test.

You guys are probably thinking I'm nuts.. "Why not just get the Latex and be done with it!". If nothing more I'm doing this for future THT builders who choose the DVC sub or other folks who have the same leaky 4 piece gaskets.

So before jumping into the latex caulk, I thought there may be a better substrate that can seep into the gaskets vertical gap crevice better. After doing some more researching tonight about common adhesives people use to recone and refoam their speakers 2 separate adhesives stood out.

Aleen's Tacky Glue and Weldbond.

Most of the discussion I have seen on these 2 glues is that they are flexible when dry, durable, Have the consistency of white glue and don't hurt foam surrounds.

So off I went to Blicks Arts store and bought Weldbond, Than over to JoAnns for Aleen's Tacky Glue. Super cheap, both under $4.

Weldbond is actually used on the space shuttle and people claim it adhere's to just about everything. Aleen's tacky glue is often used to repair minor punctures to foam surrounds and remains flexible and strong.

For my primative test I put many dabs of glue on pieces of scrap wood. I put a rag ontop of glue dabs which will be my test for adhesion to a flexible material.

Tomorrow I will see if the glue is flexible and test how it adhered to the cloth. The Titebond is in the pic for nothing more than the control for this test.

You guys are probably thinking I'm nuts.. "Why not just get the Latex and be done with it!". If nothing more I'm doing this for future THT builders who choose the DVC sub or other folks who have the same leaky 4 piece gaskets.

Re: myn's Tuba HT Build Thread

Interested to see how it turns out, never used either of those products...

JSS

JSS

Re: myn's Tuba HT Build Thread

Hey, hey hey! (Fat Albert style), carry on!myn wrote:You guys are probably thinking I'm nuts.. "Why not just get the Latex and be done with it!". If nothing more I'm doing this for future THT builders who choose the DVC sub or other folks who have the same leaky 4 piece gaskets.

Thanks.

TomS