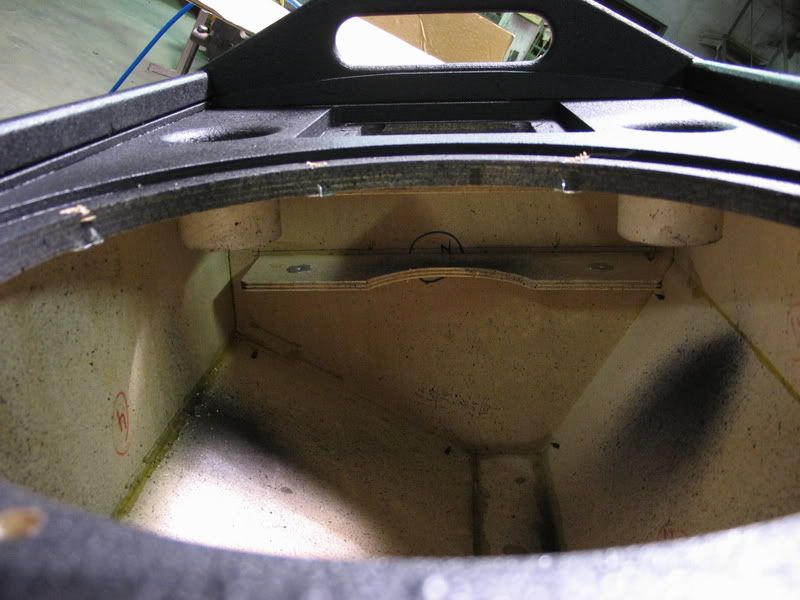

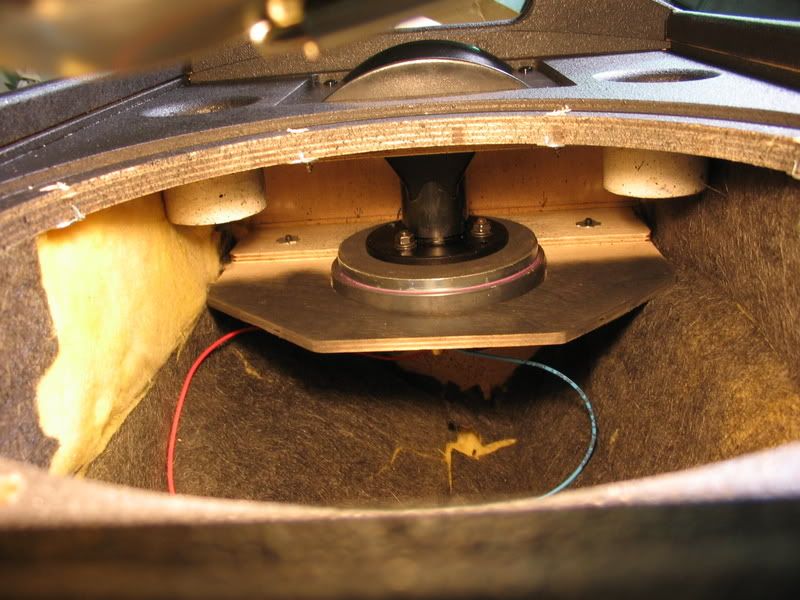

The new horn drivers are shorter and have no threaded hole in the back. In fact I don't recall seeing any replacement drivers with this feature.

I would like to support the new drivers somehow as I am sure a few good drops of the cabinet might crack the plastic horn lens with 4 lbs hanging unsupported off of the end.

Anyone have any ideas of how to support the driver? Tried and tested solutions?

PS - These will be temporary until I get a chance to build me some DR250's.