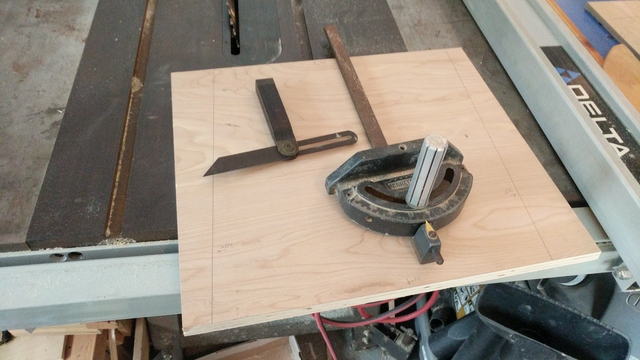

After some looking at the speakers I figured out I'd have to extend the depth a few inches to clear the really monstrous magnets and deep cone of the Eminence 12s. No problem, just add 3" here, here, and oh there too. The sides, back, and top and bottom were pretty straightforward; getting the compound angles for the baffle boards setup and cut right on the table saw... well, not so much. I had bought what I thought was sufficient excess plywood to cover the XF212 and another project I had in the wings; as it was, I botched THREE, count 'em THREE, sets of baffles. Kept putting the bevels on the wrong edges or facing the wrong way, and had the center of the cabinet measured and marked wrong for the set I thought I had right.

My relief was enormous when I finally had a test fit that worked. The fit wasn't surgically precise, but the PL glue would doubtless a multitude of sins when it was time to glue 'em in. Got the speaker holes measured, marked, and cut out with the trusty Bosch jigsaw, the glue gun was brought out, and it all went together very nicely.

I've never been a fan of the single strap handle on top of the case approach; it makes for a wobbly "sit" if you put an amp or laptop or other stuff on top of the cab. My go-to is those spring loaded flip out handles in the sides. They install inset into the sides, so I cut clearance holes...

...and then patched 'em on the inside to ensure airtightness if I decided to run the cab sealed in the future.

It was pretty quick work to make the mounting blocks for the grille, then it was time to mask the living daylights out of it and head for the great outdoors with the rattlecans. The idea was to paint everything behind the grille black, and then hit the rest of the cabinet with a bunch of coats of Watco Danish Oil. I was looking for a look like the old Legend guitar amps from the 1980s, which I remembered with a certain fondness.

Once I got the baffle area primed and painted, I applied about a dozen coats of the Watco Danish Oil. Once the final coat was on, I pulled a stunt I've done on several previous projects and speed-cured the stuff by baking each side for a couple days under a murderously hot halogen work lamp. Works great!

Finish cured, speakers mounted, jacks installed on the back (it's wired for stereo - each channel of my amp drives one speaker). I've yet to have the time to put the grille together.

Off to church with it.