While building my DR250's I became a little concerned with the air quality in the shop. You could see the fine dust in the air and could feel it in your lungs after a breath or two. I use a respirator during sanding and cuts but I don't wear it when doing other work. Also, dust was settling 35 feet or more from my work area in all directions and vacuuming that space was becoming a pain. I took a break from the DR's to build an air cleaner. Commercial air cleaners are expensive and you need proprietary filters for them so I thought I could do better:

I started out with an inline 10" duct fan. They are available on e-bay for about $110 and the 10" model moves 760 CFM. They are fairly quiet, the 10" is 52 dB's. The 12" would move more air at 1200 CFM but is also louder at 55 db's. They were sold out of 12"ers so I went with the 10" model:

I then went and bought some furnace filters. I went with a 16" x 25" x 1" merv11 fine filter (1 micron), a 16" x 25" x 4" merv8 medium filter (5 micron), and a blue washable pre-filter.

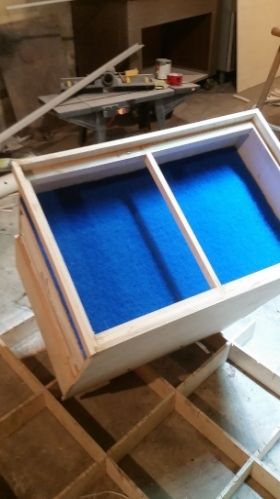

I didn't have too much of a plan, I used the filters as a guide for the box dimensions then I just cut out a bunch of 1" strips to make slots for the filters and cut out a hole for the fan. I placed a center strip to help support the filter. I also made an extra 4" slot for future use. I used about 3/4 of a sheet of 1/2" baltic birch that I had for my DR250's, PL and a brad nailer and it didn't take very long:

Test fitting the fine filter:

... the main 4" thick filter:

Here if you look close at the left you can see how I left the slots open to install the filters:

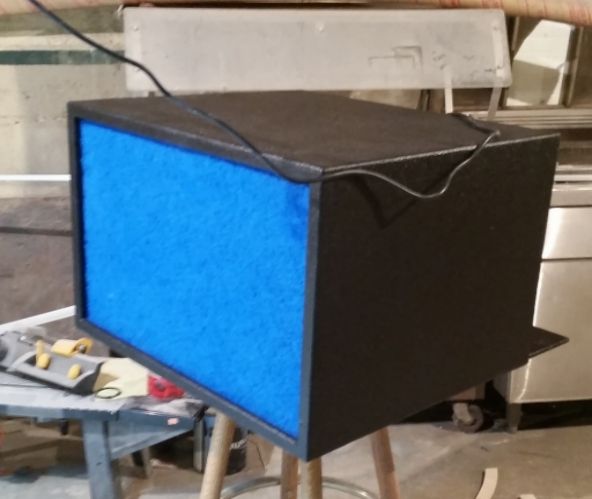

It isn't in the image but I also rimmed the front with 1" strips and made an access cover to close off the filters entrance. I left a touch of overhang on all the joints so I then used a router with a flush cutting bit to trim any excess off. Then a round over bit with the router, a quick sand with 60 grit on the random orbital, and then 2 coats of duratex:

You can sort of make out the access cover. It is held with 2 screws and rimmed with thin open cell foam. It still needs rubber feet and some hooks to hang it from the ceiling and I may even add some corner protectors.

It took me 2 half days in the shop to make including shopping for the filters and waiting for the duratex to dry. I spent around $200 and I feel it out performs $400 commercial units. How? Well, I don't need expensive proprietary filters. The furnace filters are available anywhere and in any grade (merv rating) you want. The extra 4" slot I made I plan on making a frame lined with expanded metal and window screen and filling the frame up with 20 lbs of activated carbon to use as an organic vapour solvent filter. That will clear the shop of any noxious fumes from paint, bondo, glue, etc. 20 lbs of carbon should be good for at least a year and a half of continuous 24h/day use and commercial shop units don't even have that option. Even the thick "greenhouse" carbon filters used for indoor "farming" are only 2" thick. Also, if 52 dbs get annoying, they also make mufflers for those inline duct fans.

First impressions are that I don't know how I lived without one. The air is very clear. There used to always be a haze directly under these super bright LED aquarium lights I use as overheads over my work surface when cutting and that haze is non-existant now even right after sanding. I almost didn't finish the project as I didn't want to unplug it to round over the corners and sand it without it running. The 760 CFM is plenty for me as you can feel that air moving anywhere in that space and it is a pretty big space. If I drop a pinch of fine dust about 3' in front of it, you can see it getting sucked right in. It is also very quiet, my heat gun is much much louder. It is about as loud as my fan in my computers video card while gaming.

The project turned out better than I had planned, I only wish I did it sooner. The $200 I spent was an investment in my lungs and once that carbon filter is built even solvents won't be a bother indoors.