Any tips on buying a table saw??????

Any tips on buying a table saw??????

I'm getting ready to start my jacks, and after reading all the plans, it really looks like a table saw would make things a lot easier and more precise. I have the good fortune of living in the huge city of Atlanta, where on any given day there are a ton a table saws on c-list. Are there any particular features or capacities I should be looking for?

-

Frederic Gelinas

- Posts: 566

- Joined: Wed Jul 23, 2008 10:03 am

- Location: Saint-Pie, Quebec, Canada

Re: Any tips on buying a table saw??????

The fence is more important than the rest of the table saw in my opinion.

Frédéric Gélinas, HF Audio

Authorized Builder

HFAudio.ca

Free tone Generator

Saint-Hyacinthe, Québec, Canada

Authorized Builder

HFAudio.ca

Free tone Generator

Saint-Hyacinthe, Québec, Canada

Re: Any tips on buying a table saw??????

A TS will help you build your cabs more quickly and accurately. No doubt about that. If I could have just one "big tool" it would be my table saw. The drill press and bandsaw I don't use that often, but the TS gets used for pretty much every project I build. Cabs, bookcases, chairs, you name it.

Do you have a 220v outlet in your garage/workspace? The vast majority of "contractor type" table saws sold new in Lowes/HD run on normal 110v power, but a lot of the TSs you see on CL are "prosumer" oriented and run on 220v. They will not run on a normal 110v circuit.

What's your budget and how much space are you willing to lose to the table saw? Contractor type TS's typically are smaller and some fold up and they usually weigh less than 100 pounds. Stationary cabinet saws are big and heavy. As in 400+ pounds. How will you get it home and get it into place? These are things to think about now. My Grizzly G0690 TS weighs about 500 pounds, but I have it on a mobile, wheeled base b/c my garage is small.

Being that you are looking on CL, I'm assuming you are buying used. Nothing wrong with that. First, check the power requirements of whatever saw you're looking at. You want a saw that uses a standard 10" blade. Speaking of blades, assume you will need to buy a new blade for it. 40-tooth is a good all-purpose blade, but 80-tooth gives smoother cuts in plywood. I use a 40-tooth blade for most of what I cut, though. You can pay $10 or $50 for a blade. Somewhere in the middle is generally a good compromise.

I'm not a power tool expert, but I've learned a lot as I've researched for my own tool buys. Make sure any saw you're looking at has a riving knife or a splitter (same thing) behind the blade. It's a mandatory (IMO) safety feature. When looking at contractor saws, the fence is the most important thing. Make sure it moves smoothly and locks in place securely.

When buying used, keep price in mind. FYI, you can buy a new, contractor saw like this excellent Porter Cable for $300. That's new, in the box, with a warranty. http://www.portercable.com/products/Pro ... ctID=24026

If I was buying that exact saw used, I'd not pay more than $130-ish for it, depending on condition. Remember, you're going to shell out another $30 for a new blade.

Hope this helps.

Do you have a 220v outlet in your garage/workspace? The vast majority of "contractor type" table saws sold new in Lowes/HD run on normal 110v power, but a lot of the TSs you see on CL are "prosumer" oriented and run on 220v. They will not run on a normal 110v circuit.

What's your budget and how much space are you willing to lose to the table saw? Contractor type TS's typically are smaller and some fold up and they usually weigh less than 100 pounds. Stationary cabinet saws are big and heavy. As in 400+ pounds. How will you get it home and get it into place? These are things to think about now. My Grizzly G0690 TS weighs about 500 pounds, but I have it on a mobile, wheeled base b/c my garage is small.

Being that you are looking on CL, I'm assuming you are buying used. Nothing wrong with that. First, check the power requirements of whatever saw you're looking at. You want a saw that uses a standard 10" blade. Speaking of blades, assume you will need to buy a new blade for it. 40-tooth is a good all-purpose blade, but 80-tooth gives smoother cuts in plywood. I use a 40-tooth blade for most of what I cut, though. You can pay $10 or $50 for a blade. Somewhere in the middle is generally a good compromise.

I'm not a power tool expert, but I've learned a lot as I've researched for my own tool buys. Make sure any saw you're looking at has a riving knife or a splitter (same thing) behind the blade. It's a mandatory (IMO) safety feature. When looking at contractor saws, the fence is the most important thing. Make sure it moves smoothly and locks in place securely.

When buying used, keep price in mind. FYI, you can buy a new, contractor saw like this excellent Porter Cable for $300. That's new, in the box, with a warranty. http://www.portercable.com/products/Pro ... ctID=24026

If I was buying that exact saw used, I'd not pay more than $130-ish for it, depending on condition. Remember, you're going to shell out another $30 for a new blade.

Hope this helps.

T48 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=20315

OTop12 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=19214

OTop12 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=19214

- Hackomatic

- Posts: 400

- Joined: Thu Jun 25, 2009 8:11 am

- Location: West TN

Re: Any tips on buying a table saw??????

I thought most units allowed you to wire for either/ or. I have an O-L-D Craftsman radial arm that can be wired for 110 or 220v. I prefer 220 because there seems to be a significant torque increase.miked wrote: The vast majority of "contractor type" table saws sold new in Lowes/HD run on normal 110v power, but a lot of the TSs you see on CL are "prosumer" oriented and run on 220v. They will not run on a normal 110v circuit.

Dave H

-

Charles Warwick

- Posts: 586

- Joined: Mon Mar 09, 2009 1:25 am

- Location: Ames, Iowa

Re: Any tips on buying a table saw??????

I'd first decide how much room you want to devote to the tablesaw, and that will help narrow things down a good bit. There are 4 major styles from smallest to largest:

-Jobsite Saws (like the porter cable linked above)

-Contractor Saws (Like jobsite but don't fold up)

-Hybrid

-Cabinet Saw

Any of these saws will be completely sufficient for building speakers. If you buy a jobsite saw, check it for wobble, some of the cheap ones are more unstable than make me comfortable, but the Bosch Jobsite is fantastic, and the Porter Cable has very good reviews as well. Otherwise, you can easily pick up a contractor style saw off CL for pretty cheap.

Look for a fence that locks strong (i.e. when you lock it down, it doesn't slide around when you push on it), a good top (cast iron is great, but just look at the general condition of the slots and check that the miter gauge slides well), and also a decent motor. Generally, just about any 15amp motor is enough for plywood. If you can manage it a few safety features like a riving knife, anti-kickback pawls, or a blade guard are very nice.

-Jobsite Saws (like the porter cable linked above)

-Contractor Saws (Like jobsite but don't fold up)

-Hybrid

-Cabinet Saw

Any of these saws will be completely sufficient for building speakers. If you buy a jobsite saw, check it for wobble, some of the cheap ones are more unstable than make me comfortable, but the Bosch Jobsite is fantastic, and the Porter Cable has very good reviews as well. Otherwise, you can easily pick up a contractor style saw off CL for pretty cheap.

Look for a fence that locks strong (i.e. when you lock it down, it doesn't slide around when you push on it), a good top (cast iron is great, but just look at the general condition of the slots and check that the miter gauge slides well), and also a decent motor. Generally, just about any 15amp motor is enough for plywood. If you can manage it a few safety features like a riving knife, anti-kickback pawls, or a blade guard are very nice.

- SoundInMotionDJ

- Posts: 1750

- Joined: Thu Mar 15, 2007 1:31 pm

- Location: DFW, Texas

- Contact:

Re: Any tips on buying a table saw??????

If you can lift the saw by yourself, it is NOT safe to push a full sheet of ply across the top. My saw has a full cast iron top and cast iron wings. If the saw is a "contractors" style, and you can lift it...then get about 200 pounds of sandbags and weight down the stand until you can't lift it.

110v is fine for 1/2" pine or BB ply. If you get into solid hardwoods then 220v makes a difference. But for any of Bill's speakers, 110v is OK.

Toss any blade that comes with the saw, and get an 80 tooth blade. Spend about $40. Freud, Irwin, and others all make reasonable blades in that price range.

Build the cross cut sled before you do anything else. Make it out of the same ply you have planned for the speakers. This is one of the tools that more than pays for any amount of time invested in making it. Take your time, and make it as square to the blade as you possibly can. Plan to rebuild this sled every few years. Also, plan to "tack down" some jigs as you build cabinets. For instance, I have holes drilled in the crosscut sled for dowels that take the jigs to cut piezos for DRs.

Build an outfeed table at "the same" (or about 1/2" less) than the height of the saw. Make it large enough to catch a full sheet of ply that has been split down the middle the long way. My outfeed table doubles as a router table.

Build an infeed support that will let you push a full sheet of ply over the saw longways. Mine double as some sawhorses and an assembly table stand.

Get at least a shop vac for dust collection. Use it everytime you run the saw. If you ever notice that you are making "dust" instead of "little chips" with the saw blade, the blade needs attention. You may need to clean the pine pitch off the blade (mineral spirits does the job), or you may need to get a sharper blade. I do not bother to sharpen $40 blades, I use them till they are dull then toss. Others will do different things.

Good fences make good saws great. In practical terms, for cabinet building the crosscut sled is MUCH more critical. However, if you are using a "stock" fence that is not 100% repeatable in terms of setup...then you must do some additional planning. Cut ALL the stock for interior panels at the SAME time...that will ensure a consistent width. I use the "stock" fence...and it causes me to do some additional work when I use the fence. BUT, about 85% of my cuts involve the crosscut sled...in one form or another.

110v is fine for 1/2" pine or BB ply. If you get into solid hardwoods then 220v makes a difference. But for any of Bill's speakers, 110v is OK.

Toss any blade that comes with the saw, and get an 80 tooth blade. Spend about $40. Freud, Irwin, and others all make reasonable blades in that price range.

Build the cross cut sled before you do anything else. Make it out of the same ply you have planned for the speakers. This is one of the tools that more than pays for any amount of time invested in making it. Take your time, and make it as square to the blade as you possibly can. Plan to rebuild this sled every few years. Also, plan to "tack down" some jigs as you build cabinets. For instance, I have holes drilled in the crosscut sled for dowels that take the jigs to cut piezos for DRs.

Build an outfeed table at "the same" (or about 1/2" less) than the height of the saw. Make it large enough to catch a full sheet of ply that has been split down the middle the long way. My outfeed table doubles as a router table.

Build an infeed support that will let you push a full sheet of ply over the saw longways. Mine double as some sawhorses and an assembly table stand.

Get at least a shop vac for dust collection. Use it everytime you run the saw. If you ever notice that you are making "dust" instead of "little chips" with the saw blade, the blade needs attention. You may need to clean the pine pitch off the blade (mineral spirits does the job), or you may need to get a sharper blade. I do not bother to sharpen $40 blades, I use them till they are dull then toss. Others will do different things.

Good fences make good saws great. In practical terms, for cabinet building the crosscut sled is MUCH more critical. However, if you are using a "stock" fence that is not 100% repeatable in terms of setup...then you must do some additional planning. Cut ALL the stock for interior panels at the SAME time...that will ensure a consistent width. I use the "stock" fence...and it causes me to do some additional work when I use the fence. BUT, about 85% of my cuts involve the crosscut sled...in one form or another.

10 T39S + 10 DR200 + 1 T48

-

CoronaOperator

- Posts: 1648

- Joined: Wed Mar 25, 2009 7:07 pm

- Location: Medicine Hat, Alberta, Canada

Re: Any tips on buying a table saw??????

If you are buying used bring a straight edge with you to check the top for flatness. You also want to check the miter slots for smoothness; any nicks, dents or heavy corrosion will give you problems. You also want to make sure your throat plate can accept a zero clearance insert.

Built:

17" width 10" driver Autotuba

2 x 29" width dual Lab12 Tuba60

6 x DR250 2510/asd1001

In progress:

2 x DR250 2510/asd1001

For best results, point the loud end of the array towards the audience

17" width 10" driver Autotuba

2 x 29" width dual Lab12 Tuba60

6 x DR250 2510/asd1001

In progress:

2 x DR250 2510/asd1001

For best results, point the loud end of the array towards the audience

Re: Any tips on buying a table saw??????

I recently found a very good deal on Craigslist - I spent about a month hunting. I found a cabinet style saw (search unisaw, powermatic, jet) for $500. One thing to watch for is that many older unisaws are 3-phase, and you'll need a phase converter or variable speed drive to run them off of standard house wiring. I've been very happy with my purchase. The difference from doing things with a circular saw is night and day.

Built:

1 Omni-15 Tall Boy

2 DR250s

2 Titan 39s

1 Omni-15 Tall Boy

2 DR250s

2 Titan 39s

Re: Any tips on buying a table saw??????

So many awesome replies!

Notice that we are all saying many of the same things. Facts are facts. Bet you did not think something as simple as buying a used powertool would be so complicated, right?

Especially b/c you are looking at buying used, pay particular attention to the power requirements of whatever saw you're looking at. And keep in mind what I said above about buying new vs. used, price-wise. It really is a buyers' market; USED tools just aren't worth what the sellers wish they were worth.

Notice that we are all saying many of the same things. Facts are facts. Bet you did not think something as simple as buying a used powertool would be so complicated, right?

Especially b/c you are looking at buying used, pay particular attention to the power requirements of whatever saw you're looking at. And keep in mind what I said above about buying new vs. used, price-wise. It really is a buyers' market; USED tools just aren't worth what the sellers wish they were worth.

T48 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=20315

OTop12 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=19214

OTop12 build thread: http://billfitzmaurice.info/forum/viewt ... 30&t=19214

Re: Any tips on buying a table saw??????

Thanks for all the replies! I may just end up buying new, as I clearly don't have the skills to evaluate the saws on craigslist. I do have one question though--what kind of rip capacity is optimal? Looking at the cut sheets for the jacks, it looks like I would need something up to 22". Is that correct?

- Bill Fitzmaurice

- Site Admin

- Posts: 29062

- Joined: Tue May 02, 2006 5:59 pm

Re: Any tips on buying a table saw??????

+1. My saw is a $100 Delta, with a $200 fence. Make sure that what you get either has a top quality fence or allows you to add one. Most under $200 saws have the fence guide an integral part of the top, so it can't be removed and you can't put a better fence on it. You also don't need a huge table, just make your own extension wings to make it as wide as you want.Frederic Gelinas wrote:The fence is more important than the rest of the table saw in my opinion.

Re: Any tips on buying a table saw??????

So how do you tell if the fence is good? I was obvious to me that the floor model at Harbor Freight was not good, as I could see that the fence would not clamp square with any repeatability. Is it mainly a matter of clamping square and tight?

- Bill Fitzmaurice

- Site Admin

- Posts: 29062

- Joined: Tue May 02, 2006 5:59 pm

Re: Any tips on buying a table saw??????

It costs $200 or more as an after-market accessory. I have this one, which I modded to place the full 35 inch capacity to the right, none to the left.rpt50 wrote:So how do you tell if the fence is good?

http://www.mulecab.com/M1025Rip.html

Re: Any tips on buying a table saw??????

Wow, that's quite the fence. One can even use jigs on it. And, it's similar to the Bessemeyer fence ....which was something that I have been contemplating (or DIY one).

TomS

- Bill Fitzmaurice

- Site Admin

- Posts: 29062

- Joined: Tue May 02, 2006 5:59 pm

Re: Any tips on buying a table saw??????

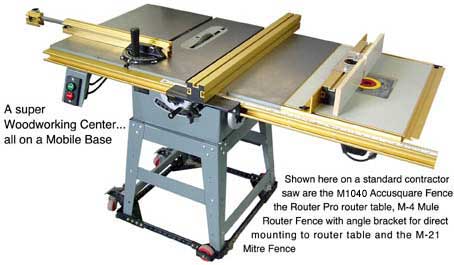

My saw looks like this, with the right wing doubling as a router table:Tom Smit wrote:Wow, that's quite the fence. One can even use jigs on it. And, it's similar to the Bessemeyer fence ....which was something that I have been contemplating (or DIY one).

One difference is that my base is bolted to the floor, and there's a pivot installed between the saw and base, so the entire top can rotate. I also have outlets on the front of the saw base for plugging in other tools, they, the saw and router getting power from an outlet installed in the floor under the base, so there are never any power cords under foot.