Yours must be four times as expensive and unmeasurably more accurate.Harley wrote:Yeah, but ours had that polychromatic stabilised quadratic doofer cunningly positioned planar to the hyperbolic co-ordinates of the theoretical transducer position along with the modified double overhead locking cam holder and I believe that really set us apart in jig technology Leland.

The journey begins.. 16 T60's and 12 DR280's!!

- Chris_Allen

- Posts: 3358

- Joined: Wed Jul 11, 2007 2:43 pm

- Location: Huddersfield, UK

Re: The journey begins.. 16 T60's and 12 DR280's!!

Built:

6xDR200, 2xT39, 2xT48, 2xJack110, 1xOmni10.5, 1xAutotuba, 1xT18, 1xSLA Pro, 1xW8, 1xW10

6xDR200, 2xT39, 2xT48, 2xJack110, 1xOmni10.5, 1xAutotuba, 1xT18, 1xSLA Pro, 1xW8, 1xW10

-

Grant Bunter

- Posts: 6912

- Joined: Mon Nov 28, 2011 11:12 am

- Location: Ilfracombe Queensland Australia

- Contact:

Re: The journey begins.. 16 T60's and 12 DR280's!!

Your forgot the twin fox tails and that fact that it's red, therefore goes faster...Harley wrote:Yeah, but ours had that polychromatic stabilised quadratic doofer cunningly positioned planar to the hyperbolic co-ordinates of the theoretical transducer position along with the modified double overhead locking cam holder and I believe that really set us apart in jig technology Leland.LelandCrooks wrote:That jig is very familiar. Almost the same as what Harley and I came up with.

Built:

DR 250: x 2 melded array, 2x CD horn, March 2012 plans.

T39's: 4 x 20" KL3010LF , 2 x 28" 3012LF.

WH8: x 6 with melded array wired series/parallel.

Bunter's Audio and Lighting "like"s would be most appreciated...

DR 250: x 2 melded array, 2x CD horn, March 2012 plans.

T39's: 4 x 20" KL3010LF , 2 x 28" 3012LF.

WH8: x 6 with melded array wired series/parallel.

Bunter's Audio and Lighting "like"s would be most appreciated...

Re: The journey begins.. 16 T60's and 12 DR280's!!

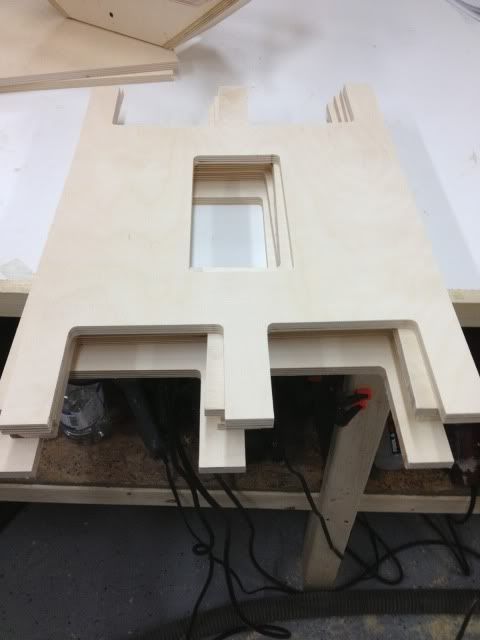

So today I realized that I probably should have built one first before doing 6 at a time.. When I make a mistake its x6

Any way made this jig to simplify the woofer baffle..

and here's all six of them, well 12 of them if you count the ones i screwed up on..

Any way made this jig to simplify the woofer baffle..

and here's all six of them, well 12 of them if you count the ones i screwed up on..

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

-

Grant Bunter

- Posts: 6912

- Joined: Mon Nov 28, 2011 11:12 am

- Location: Ilfracombe Queensland Australia

- Contact:

Re: The journey begins.. 16 T60's and 12 DR280's!!

errr human error often intervenes huh.

The "wasted" ply is probably not a frustrating as the wasted time.

Sorry, can't offer a template...

The "wasted" ply is probably not a frustrating as the wasted time.

Sorry, can't offer a template...

Built:

DR 250: x 2 melded array, 2x CD horn, March 2012 plans.

T39's: 4 x 20" KL3010LF , 2 x 28" 3012LF.

WH8: x 6 with melded array wired series/parallel.

Bunter's Audio and Lighting "like"s would be most appreciated...

DR 250: x 2 melded array, 2x CD horn, March 2012 plans.

T39's: 4 x 20" KL3010LF , 2 x 28" 3012LF.

WH8: x 6 with melded array wired series/parallel.

Bunter's Audio and Lighting "like"s would be most appreciated...

- LelandCrooks

- Posts: 7242

- Joined: Thu May 04, 2006 9:36 am

- Location: Midwest/Kansas/Speaker Nirvana

- Contact:

Re: The journey begins.. 16 T60's and 12 DR280's!!

Wait, yours has a stabilised doofer? Mine fluctuates in and out of a quantum state. Every time I look at it.Chris_Allen wrote:Yours must be four times as expensive and unmeasurably more accurate.Harley wrote:Yeah, but ours had that polychromatic stabilised quadratic doofer cunningly positioned planar to the hyperbolic co-ordinates of the theoretical transducer position along with the modified double overhead locking cam holder and I believe that really set us apart in jig technology Leland.

If it's too loud, you're even older than me! Like me.

http://www.speakerhardware.com

http://www.speakerhardware.com

Re: The journey begins.. 16 T60's and 12 DR280's!!

Hey guys I'm going to construct a wire cutter for the urethane throat filler or possibly just make a jig to cut them on my band saw.. Anybody got any tips? Also can I use the expanded polystyrene stuff from HD? And what are you guys using to glue it in place. Thanks

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: The journey begins.. 16 T60's and 12 DR280's!!

Just did some earlier today... I use a router setup to cut the circle. Band saw would work well. I used to use a scroll saw. Then I mark the inner circle, cut out the middle (less to sand) and use a belt sander to form the angle. Goes quick. Hot glue to attach.

Re: The journey begins.. 16 T60's and 12 DR280's!!

Thanks Rick! Can I use the foam insulation board from Home Depot? Its called expanded polystyrene.Rick Lee wrote:Just did some earlier today... I use a router setup to cut the circle. Band saw would work well. I used to use a scroll saw. Then I mark the inner circle, cut out the middle (less to sand) and use a belt sander to form the angle. Goes quick. Hot glue to attach.

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: The journey begins.. 16 T60's and 12 DR280's!!

Sorry, forgot about that question- that's the stuff! Rigid closed cell. Some on here have experimented with expanding foam but it wasn't worth the trouble. If you end up gluing layers together to get the right thickness try to keep the hot melt away from the angled areas that you're gonna sand. It will melt and clog up the sanding belt... even brand new sanding belts... and hot melt doesn't like to clean off brand new sanding belts...

Like to hear if Leland has a better way to do this- but it's probably a trade secret

Like to hear if Leland has a better way to do this- but it's probably a trade secret

Re: The journey begins.. 16 T60's and 12 DR280's!!

i'm sure you could use a bench sander, plus some type of jig....

Built:

2x Tuba 30s delta12lf loaded (gone)

4x Otop12 d2512 loaded

8x t48s (18, 18, 24, 24, 30, 30) 3015lf loaded

2x AT (1 mcm, 1 gto 804)

2x SLA Pro (dayton pa6, 6 goldwood piezo loaded)

1x bastard XF208

2x OT212 (delta pro 450a loaded, eminence psd)

2x Tuba 30s delta12lf loaded (gone)

4x Otop12 d2512 loaded

8x t48s (18, 18, 24, 24, 30, 30) 3015lf loaded

2x AT (1 mcm, 1 gto 804)

2x SLA Pro (dayton pa6, 6 goldwood piezo loaded)

1x bastard XF208

2x OT212 (delta pro 450a loaded, eminence psd)

- LelandCrooks

- Posts: 7242

- Joined: Thu May 04, 2006 9:36 am

- Location: Midwest/Kansas/Speaker Nirvana

- Contact:

Re: The journey begins.. 16 T60's and 12 DR280's!!

Not any more. Tim Ard designed forms and found release agents to use the expanding foam. Worked a treat to quote my favorite Kiwi. He's no longer doing them. I now have them CNC cut, but it takes a while to get them.Rick Lee wrote:Sorry, forgot about that question- that's the stuff! Rigid closed cell. Some on here have experimented with expanding foam but it wasn't worth the trouble. If you end up gluing layers together to get the right thickness try to keep the hot melt away from the angled areas that you're gonna sand. It will melt and clog up the sanding belt... even brand new sanding belts... and hot melt doesn't like to clean off brand new sanding belts...

Like to hear if Leland has a better way to do this- but it's probably a trade secret

If it's too loud, you're even older than me! Like me.

http://www.speakerhardware.com

http://www.speakerhardware.com

Re: The journey begins.. 16 T60's and 12 DR280's!!

Thanks Rick! Great tip about the hot glue, I'm willing to bet i would of wasted a sanding belt lol.. Luckily I found 1 3/4" thick foam, it has aluminum foil on it but it peals right off.. The only thing is it comes in 4x8 sheets, but then again I need to build so many of these things..Rick Lee wrote:Sorry, forgot about that question- that's the stuff! Rigid closed cell. Some on here have experimented with expanding foam but it wasn't worth the trouble. If you end up gluing layers together to get the right thickness try to keep the hot melt away from the angled areas that you're gonna sand. It will melt and clog up the sanding belt... even brand new sanding belts... and hot melt doesn't like to clean off brand new sanding belts...

Like to hear if Leland has a better way to do this- but it's probably a trade secret

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: The journey begins.. 16 T60's and 12 DR280's!!

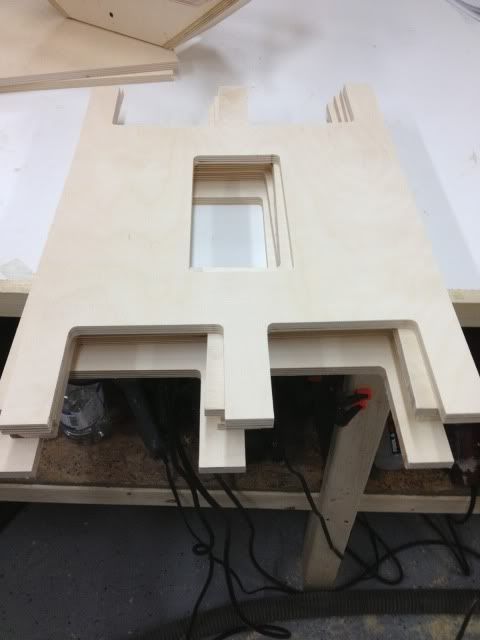

Well not much goin on but I had a few hours today to get some stuff done,,

Made this jig up to speed up attaching speaker baffle to horn/throat, worked like a charm and made for quick assembly.

10 minutes later..

oh and this guy to whip up woofer spacers..

Made this jig up to speed up attaching speaker baffle to horn/throat, worked like a charm and made for quick assembly.

10 minutes later..

oh and this guy to whip up woofer spacers..

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

-

Disco-inferno

- Posts: 219

- Joined: Thu Mar 15, 2012 6:19 pm

- Location: Tilburg, Netherlands

Re: The journey begins.. 16 T60's and 12 DR280's!!

That's some mighty nice,craftsmanship  you make building these things look easy. I really like the jigs you're constructing for assembly!

you make building these things look easy. I really like the jigs you're constructing for assembly!

Re: The journey begins.. 16 T60's and 12 DR280's!!

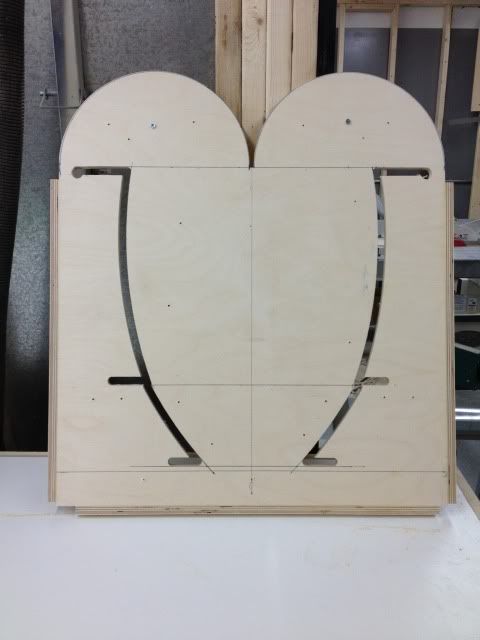

Thanks Disco! The time is definitely well spent building them.. I can really bang these things out now...Disco-inferno wrote:That's some mighty nice,craftsmanshipyou make building these things look easy. I really like the jigs you're constructing for assembly!

This one seems to be the most helpful so far.. Cuts the top and bottom panels but also makes drawing the layout lines without all that measuring and compass work.

Took me about 20 minutes to do all 12 of these once jig was finished.

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567