[img

][/img]

][/img]My Circle/Edge Guide and various router bits.

[img

][/img]

][/img]My Kreg Jig for my routers.

[img

][/img]

][/img]A closer look at my circle jigs.

[img

][/img]

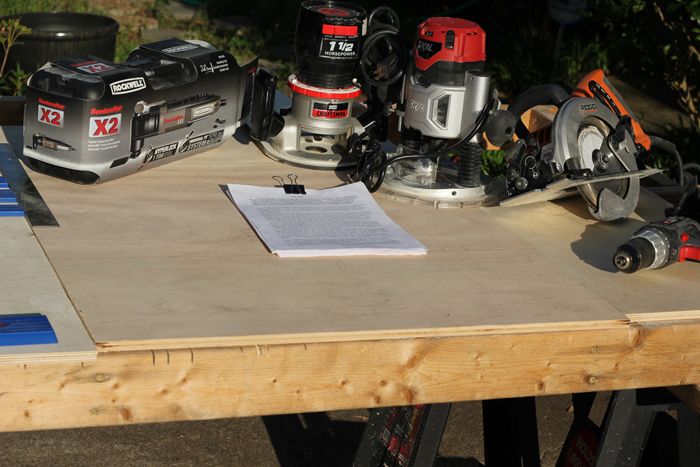

][/img]The Master Plan.

[img

][/img]

][/img]Was a bit nervous and in a rush as you can tell. This panel was trashed though as I wasn't too proud of the outcome. I have re-cut

another one and it is a hundred times better looking as I was a little more concentrated.

[img

][/img]

][/img]Hope to bring you more soon.