Slowly but surely, I'm getting there. At this point the only things left to cut are the spacer rings, the back braces and the strips that frame the rear opening. The rings will be a couple hours worth of work for me. The other parts I can knock out in a few minutes. You don't realize just how many parts are in one of these cabs until you build one! Of course, the fact I'm building 4 at the same time compounds things a bit. It will REALLY be interesting building 4 Titans at the same time, but that's at least two months off.

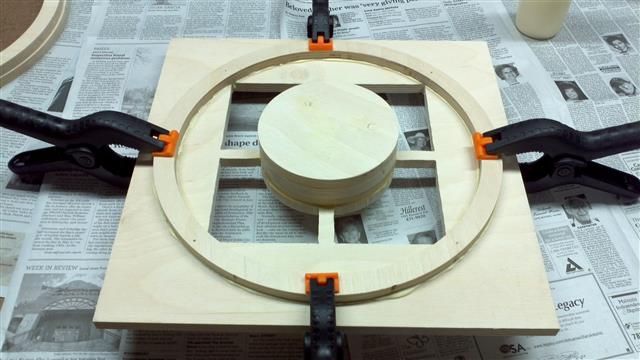

To build my phase plug extensions I drove a few sheetrock screws through the whole stack to clamp it while glue dried. This left big holes in the stack and some ply tearout when I removed the screws. It's probably not necessary, but I patched the holes with wood putty. The repair isn't 100% perfect, but it's 99% better than it was.

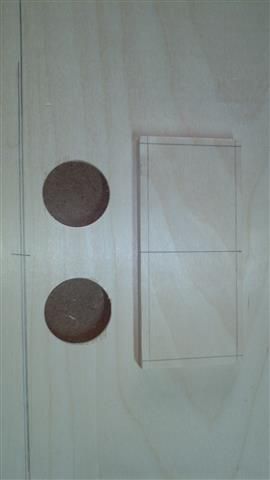

Patched/sanded plug.

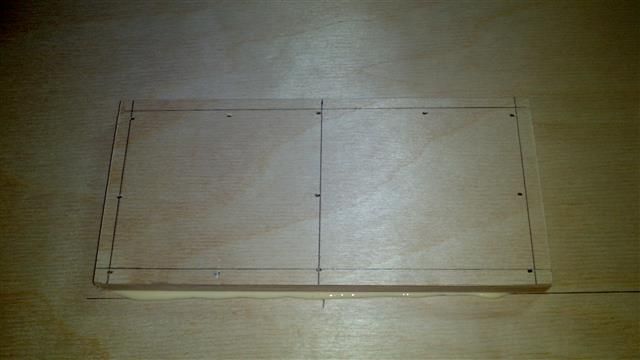

All four baffles/plugs. This is as nice as I'm making them as I've already spent almost as much time on just the baffles as I have on all the other parts.

I used a 1/2" roundover and cleaned up the handle holes in the sides. They aren't all identical, but 5 out of the 8 sides look pretty much like this. I won't show you the other 3.

They aren't bad, but they aren't perfect ovals. I chose my pics carefully.

For anyone that hasn't built Omni's before, these pics are after I cleaned up the handle holes w/120-grit sandpaper. The 1/2" roundover on both sides left a very thin raised line at the center of the hole. I just wanted to be totally clear on expectation management.

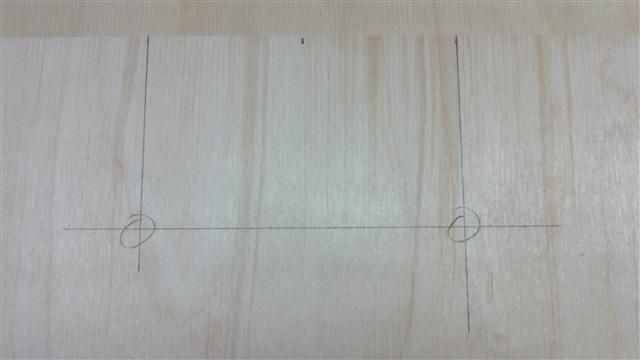

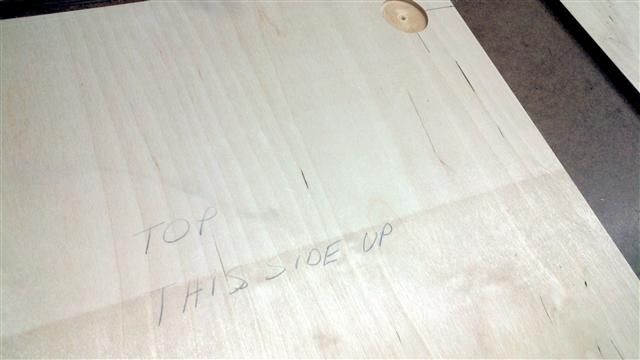

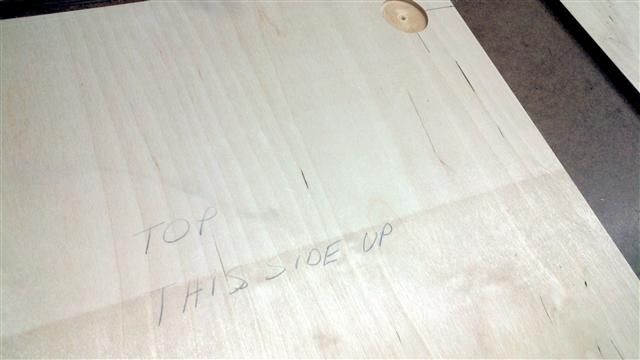

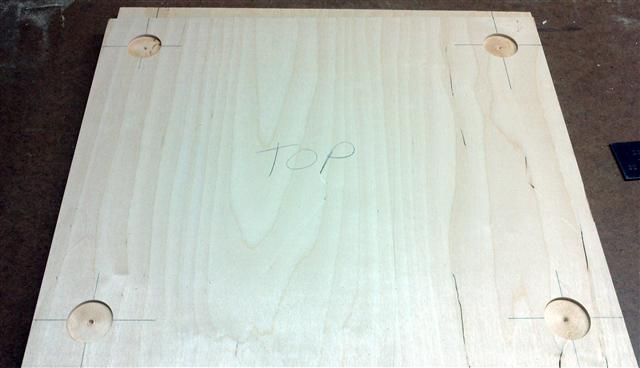

I marked the locations for the feet and clearly marked the bottoms/tops. The bottoms have the "x" marks where the feet are centered on. I'll predrill a pilot hole and stick a toothpick in there before Duratexing so I don't lose the location I so carefully marked. Ask me WHY I know to do that.

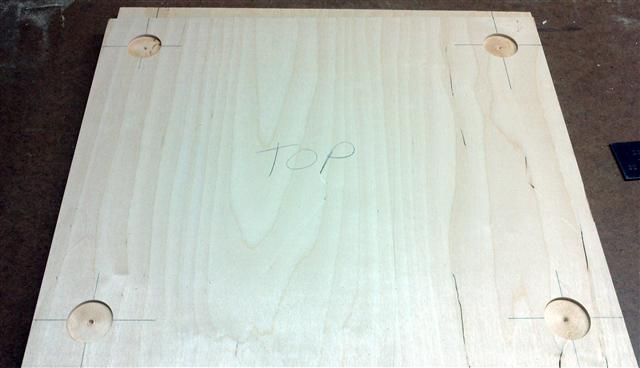

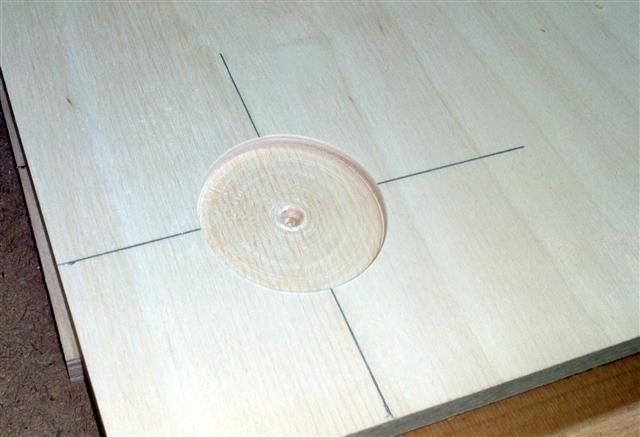

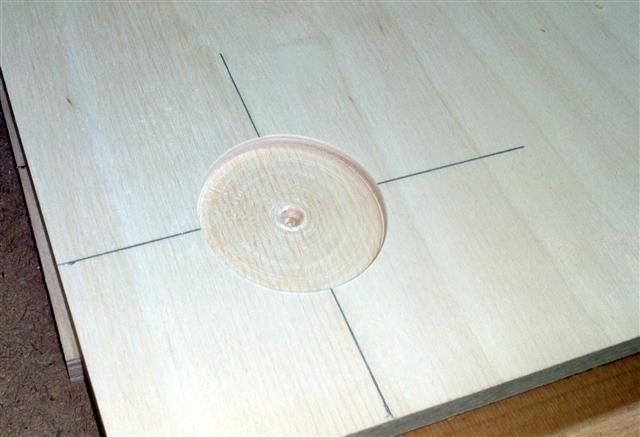

Here's a pic of one of the tops. I made recesses for the feet b/c I want the cabs to stack securely. Much easier/neater to cut these holes now before Duratexing. The recesses are about 1/8" deep. I eyeballed it on a piece of scrap before setting the depth stop on the drill press. It is what it is. The feet I'm using are the ubiquitous PennElecom F1686. These holes are 1 5/8" in diameter which leaves roughly 1/8" all around the foot...a little wiggle room, if you will.

I did some dry test fitting and it looks like everything will go together smoothly except for the throat reflectors. I might have to sand them a bit, but it's sort of hard to tell when you're holding 8 different pieces together with two hands and a knee while trying to fit a 9th piece in there...just impossible to hold everything at 90 and 45 and 26 whatever degrees.

In other news, it looks like my idea to have the tophat mounted at the cab's COG will JUST work. If I orient the driver on the baffle so that an opening in the frame lines up with where the tophat comes through, the tophat should protrude into the "cone area" on the back of the driver around 1/8" or so. Nowhwere near the back of the cone, but worth mentioining.

Just to help you visualize what I'm talking about, look at this pic (not my pic: credit to Loudsubz). See where the four nuts are on the bottom of the cab? He has an external tophat mounted there. Imagine the driver rotated so that one of those square openings in the basket directly faces the floor of the cab. The tophat comes through right there, protruding just a hair into the "cone area." If I was using one of the Neo drivers with it's wee little magnet, this would be a non-issue. But, I happen to be using the same monstrous Delta Pro as pictured here.

I'm excited about this. AFAIK, no one has done this before. It would be nice to "invent a feature" for these cabs that nobody has done before. Needless to say, not having to deal with any funky balancing act issues, tilting the speaker stands with shims, etc would be optimal.

More tomorrow. Assembly this weekend for sure.

ps

As I'm sure you've noticed, I've not mentioned anything about the piezo arrays. Haven't done a darn thing with them yet.

I want the cabs done, to include Duratex before I even mess with them. Not looking forward to that part at all.