- Wait even more for something to came up.

- Use 3/4" (18mm) plywood instead of 1/2" (12mm) to build a THT.

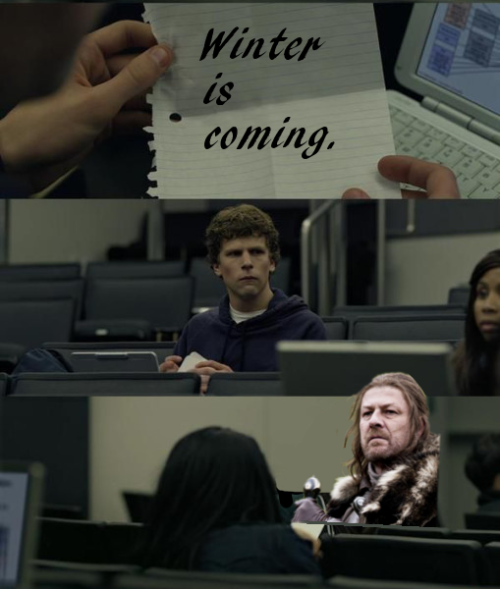

I really don't want to wait any more, and the winter is coming...

I'd rather not not work on 15 - 0 Fahrenheit (or even lower sometimes), as my work room doesn't have heating. And I guess this would affect the curing of the glue also. If I don't do it in next month or two at most, I'd have to wait for spring's higher temps.

- So can I use 3/4" plywood if I recalculate the THT box dimensions to allow for the same horn path dimensions while using 50% wider material?

- Another question, since I have some lefover chipboard, can I use it for braces (or at least for some of them)? Otherwise I will have to buy another 8'x4' plywood board and only use up to 1/4 of it (plywood is very expensive here). I don't plan another project anytime soon.

edit: grammar