Thank you all again for your help in getting me to the point where I'm ready to build my first Tuba!

I'm going to try to build this by pre-cutting all my pieces on a CNC mill and assemble them offsite. As such, while I haven't yet started to physically build the unit yet I have done a bunch of digital work as well some test with the router so I thought I should start a build thread now to fully convey the process and my thinking.

I do have a couple of questions I'm asking myself at this point so perhaps you'll have some insights there.

The basics:

Model: Tuba 30

Size: 24"

Material: 1/2" Baltic birch

Driver: Eminence Kappalite 3012LF

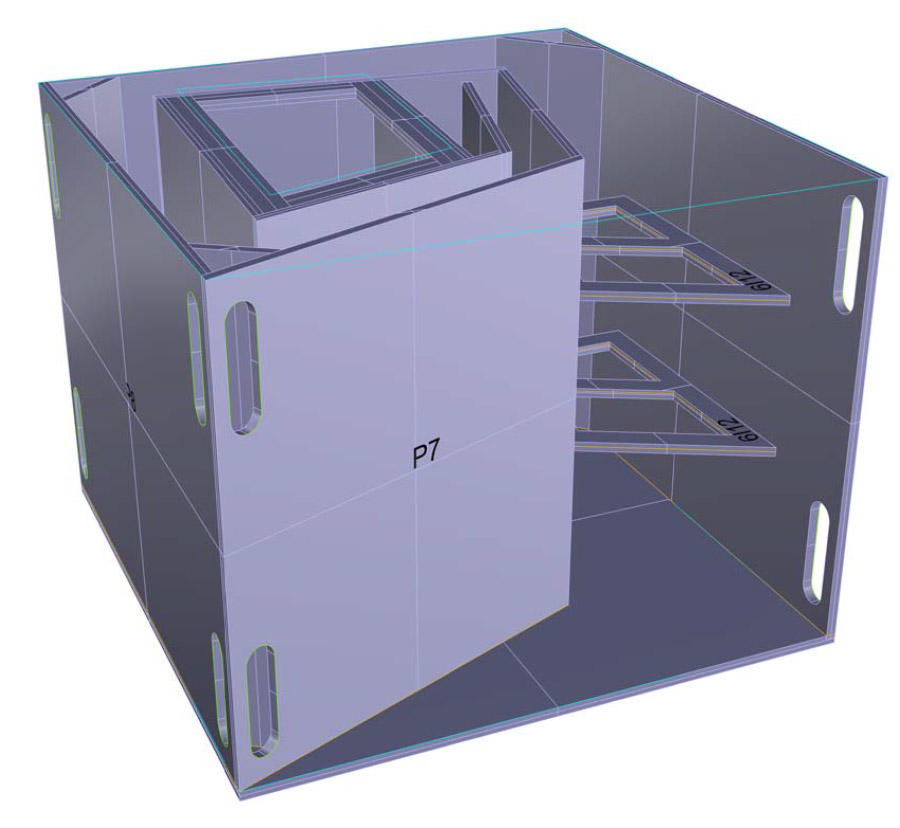

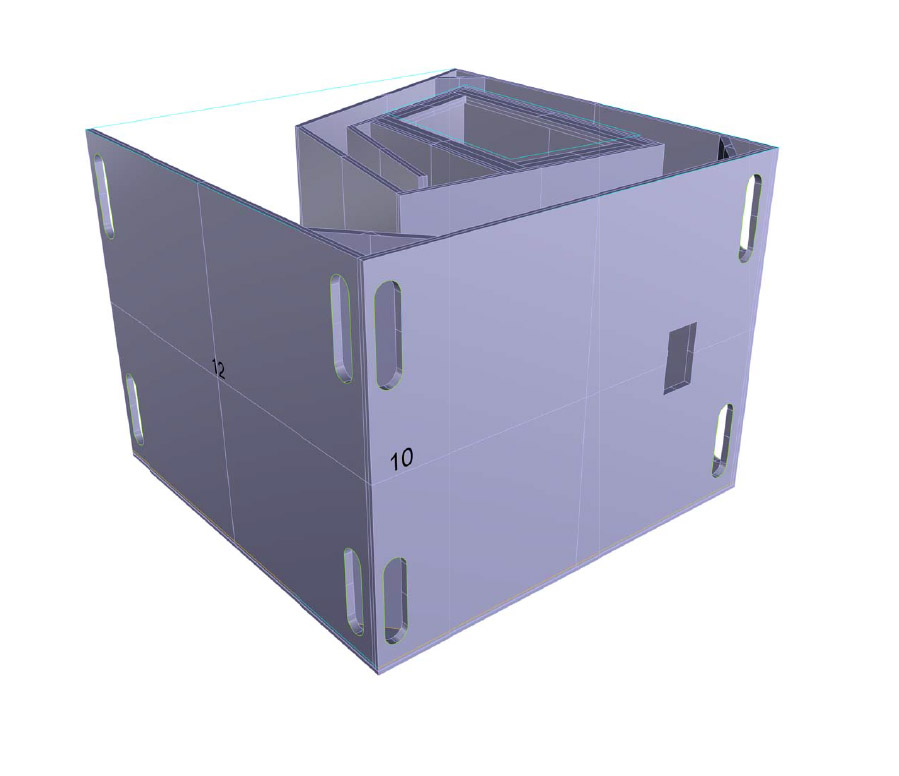

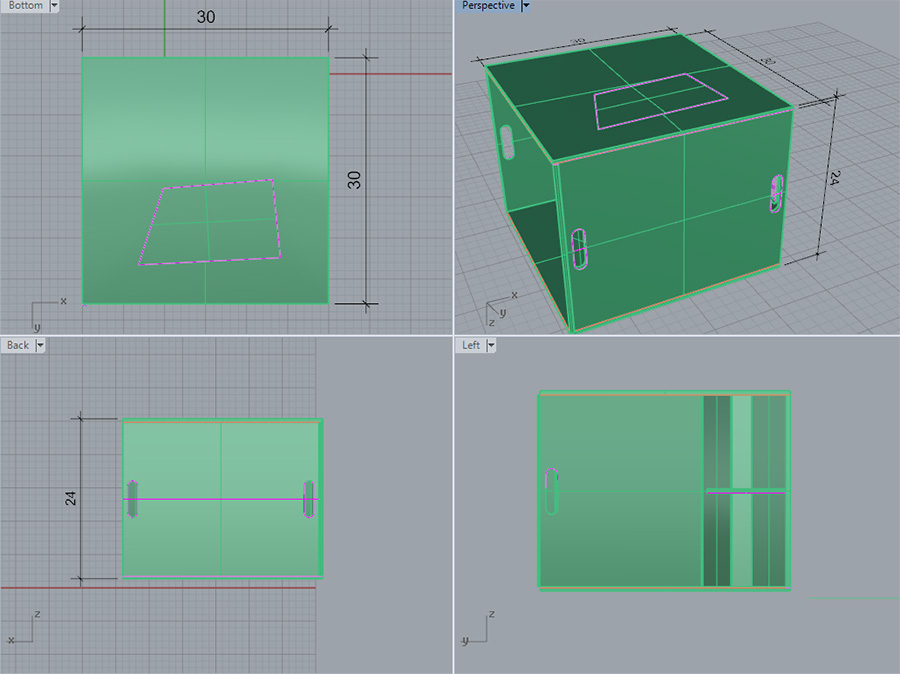

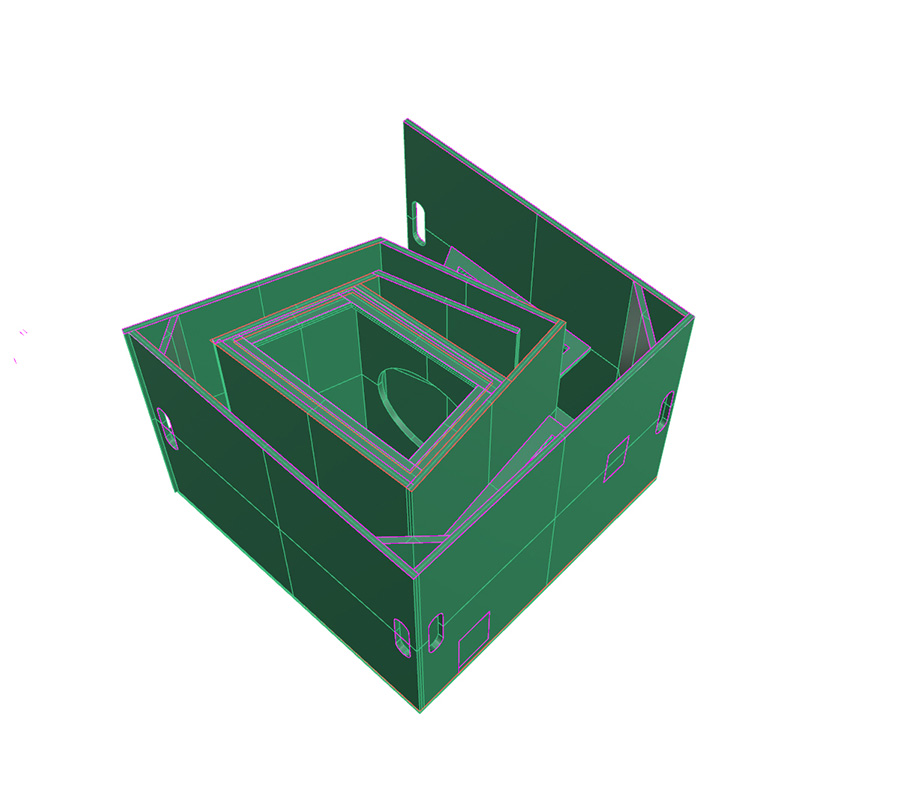

For my own sanity and to be clear about what I'm doing I decided to make a model of the 24" Tuba 30 using Rhino 3D. It may have been possible to try to program cuts directly in CAM software but the modeling approach allows me to make adjustments and ensure that, at least in model, everything fits together. Working from the plans with the existing sketch-up models as reference I essentially recreated the model Bill provides but with tighter tolerances. At first I tried working with the original model but quickly found that it didn't match the plans exactly so I ditched that idea. I followed the plan dimensions as much as I could but did have to deviate from them slightly because modelings requires a higher degree of precision than the layout instructions provide or could possibly be followed when working by hand. I decided to use dado joints on one side of the cabinet to help with alignment. I might try milling a second side with dados as well to see if I can get it to fit but with warping and build errors it seemed like a recipe for disaster. My first past a modeling assumed 1/2" thick material and 1/8" dado. More on that in a bit.

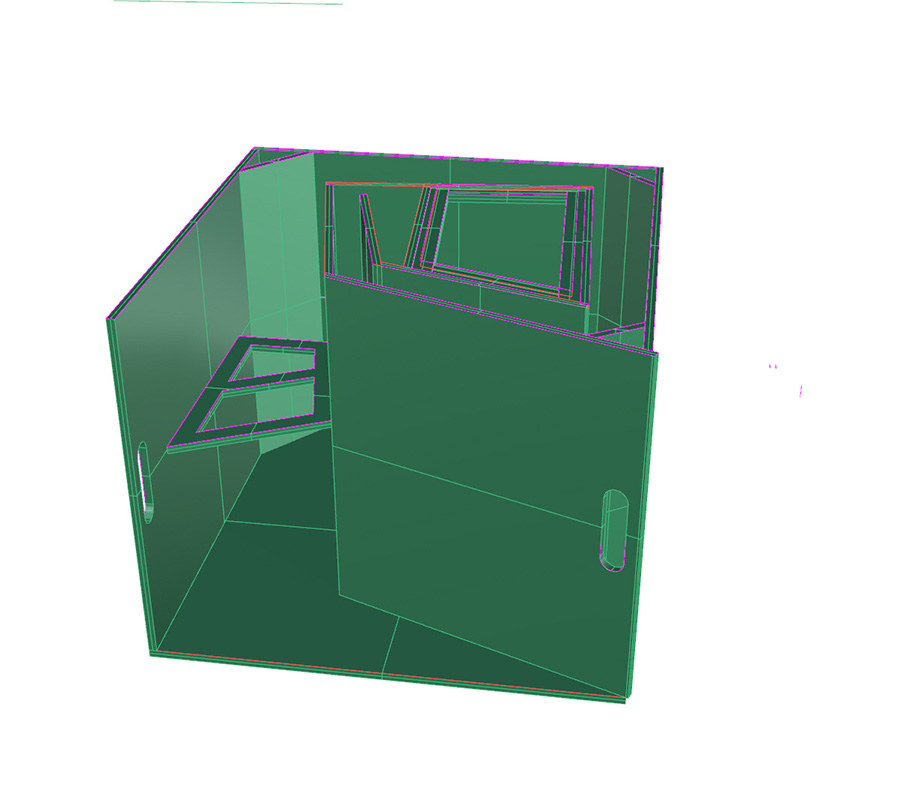

Here are some views of the Rhino model.

I've only put one set of braces in but at 24" it seems like it could use a second set - thoughts?

A side benefit of this is I could more easily place a centered connector plate on the back (panel 10). This panel is also going to hold my casters.

You'll also noticed I put a ton of handholds - overkill?

I've also decided to leave panel 7 long, to be cut later as per the plans, to give me a little wiggle room with fitting. Maybe on later cabinets I'll cut this to fit from the get-go as well.

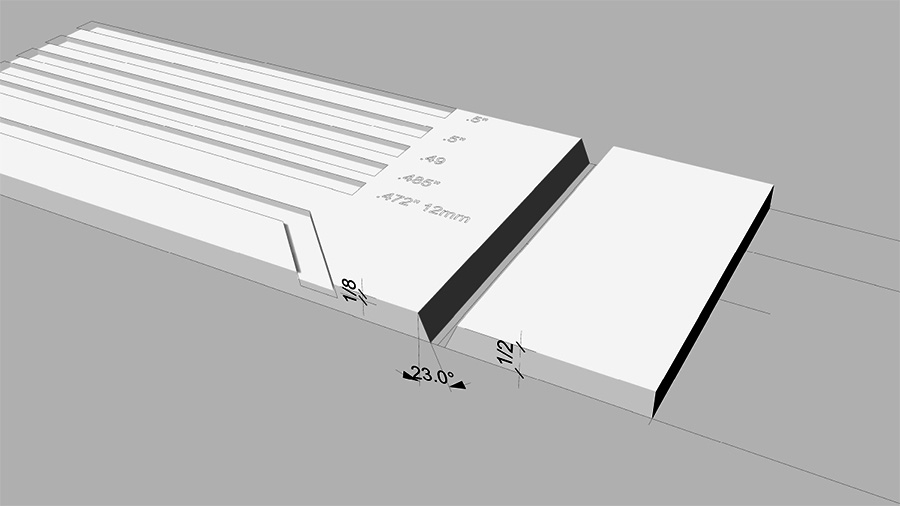

So to get all my tool paths down, sort out my dado joints, test the accuracy and quality of the milling, as well as figure out how to do the opposite facing angled cuts on panel 6 I've begun doing some small test.

As you can see the first attempt at this (the one behind) was using the wrong bit so things got kinda mashed up. It also had too loose a step over on the plunging operation which left a strip of leftover wood inside the dados. What I'm really testing here is how thick I should assume the sheets of ply are while modeling.

The panels will fit in the dados at .485" but .49" is a better fit - I can get them in there without a mallet. .5 if fine but they're a little loose and can easily tip from their groove. Obviously there will be some variation across sheets of ply and even within a single sheet but I'm considering remodeling the Tuba using .49 sheets to get this snug fit. Another question is the depth of the dados. They work at 1/8th but I think they would hold the sheet better at 3/16th so if I do remodel I'll probably shift these depths. The dados have rounded corners as I used a 1/4" bit to cut them. I could drill these out but I worry about leaks so I'm going to apply a second finishing pass with an 1/8" bit. I even have a 1/16th but that seems silly. We'll see how it goes.

Anyhow that is where I'm at! With hope I can find the time to remodel tomorrow and cut a sheet to start gluing over the weekend.