18" T30 Build

Posted: Thu Jan 08, 2015 11:57 am

Hey guys! I'm well underway in my first successful BFM build. Started with an autotuba, did it all by my self, rushed it, ruined it (braces were an after thought), and made a call for help. My buddy Jim has built 4 T36s, 8 O-Top 12s for his own sound, and also a dozen or so t30s for another friend. Of course his resume doesn't stop there, but it was the right call. He forced me to do it right and kept my a$$ in check when I wanted to rush. Painfully, I listened and the results (so far) were worth it. I had so much to learn and still more to learn as well. I'm building 2 t30's for my PA, and later plan to build some Jack 10's for the tops.

Bill, THANK YOU FOR THESE PLANS!!!

On to the build:

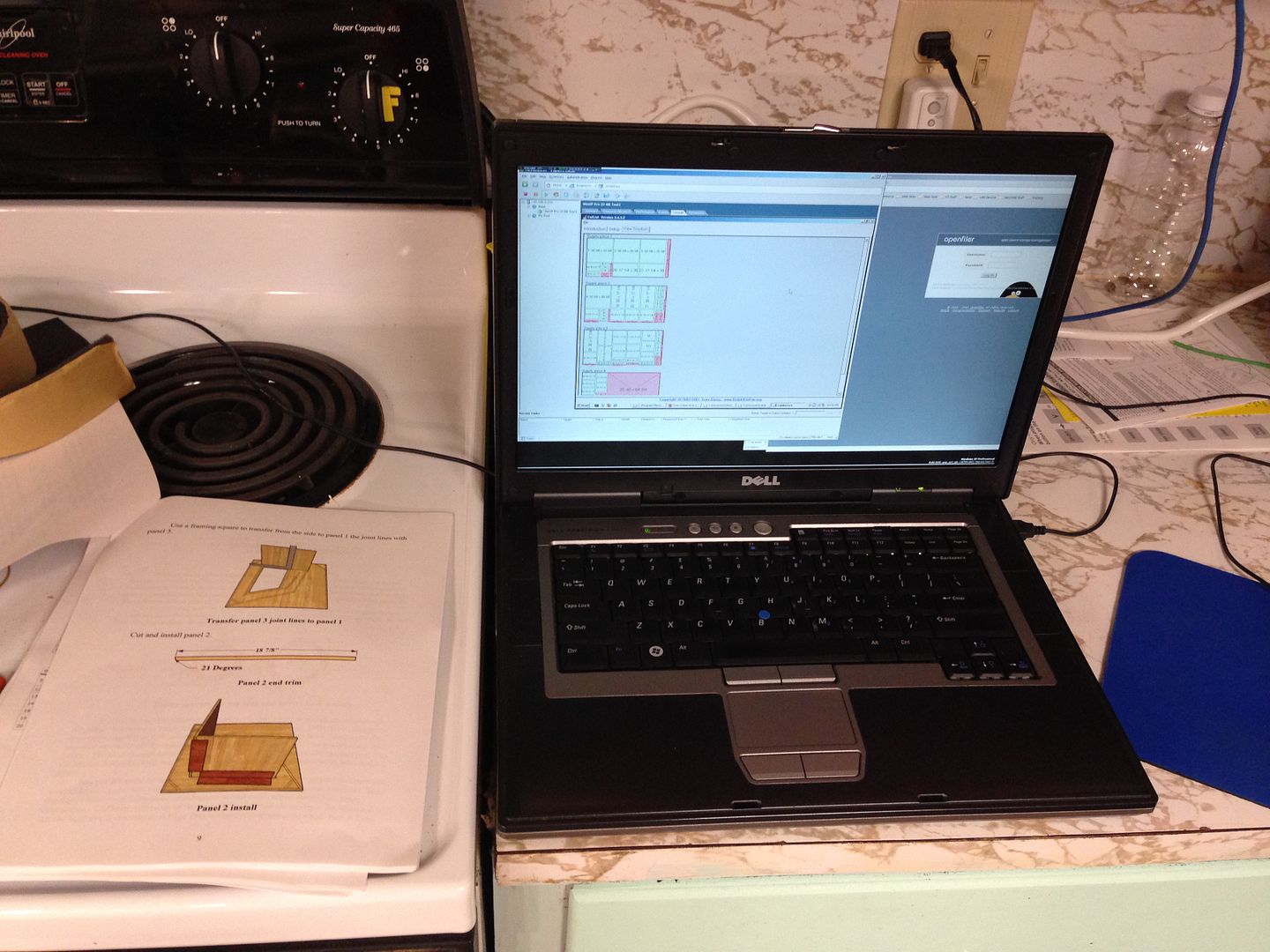

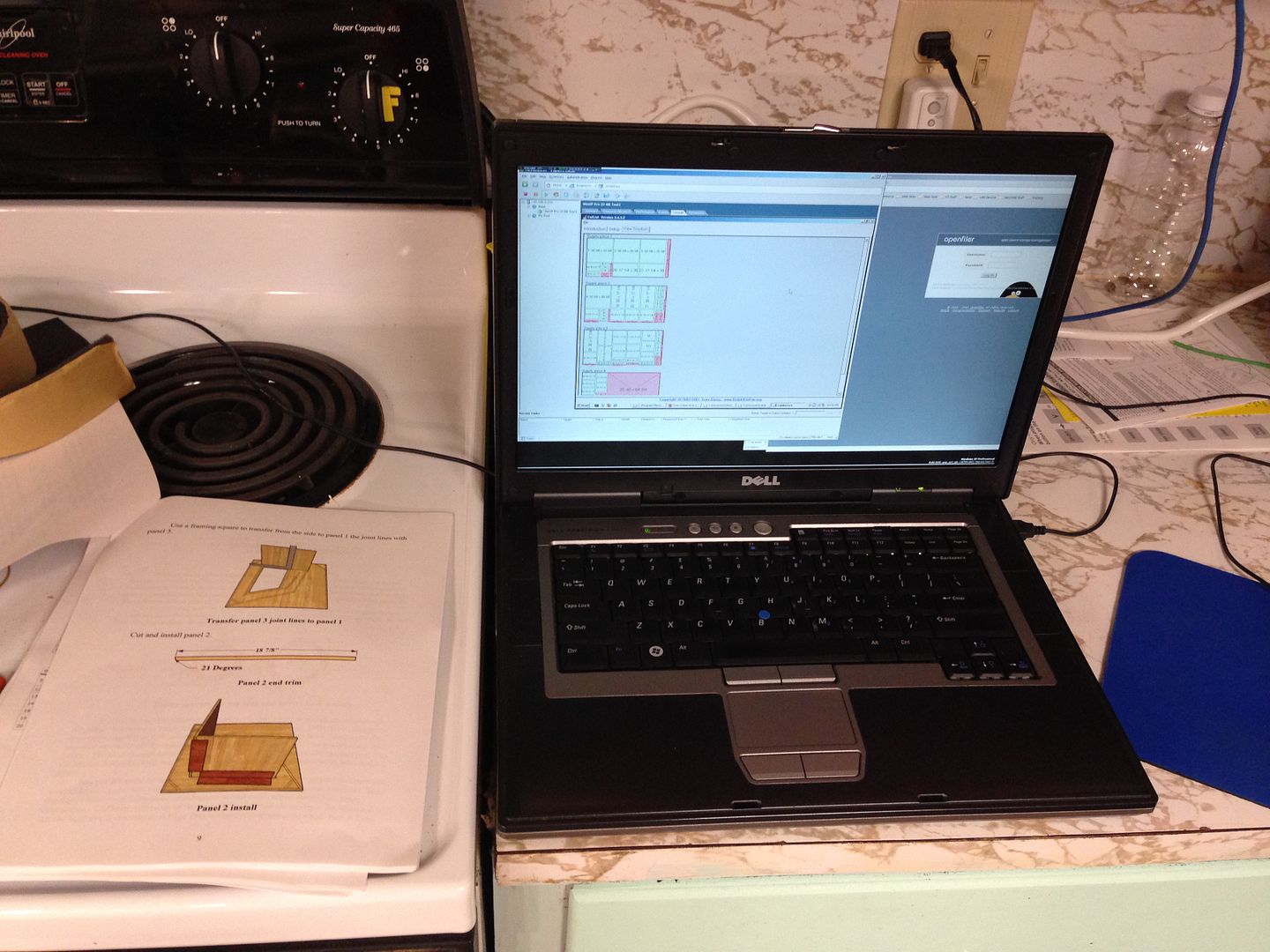

Step one... research, Research, RESEARCH and cutlist, Cutlist, CUTLIST! I decided to make mine 18" wide so I could transport them in my small SUV to gigs. And I settled on the Eminence Kappalite 3012LF. We also built my cabs mirrored so the access panels are always up or out.

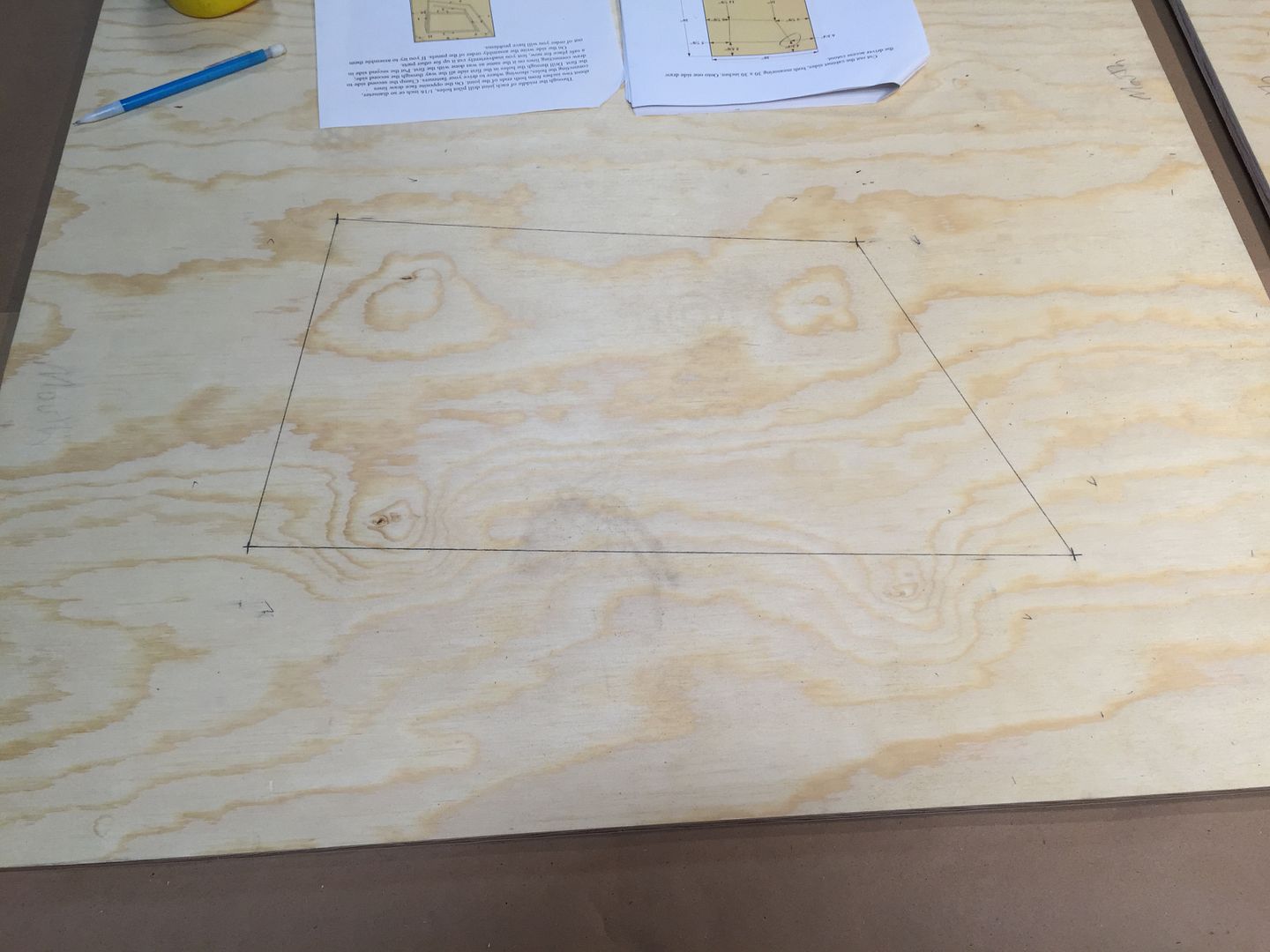

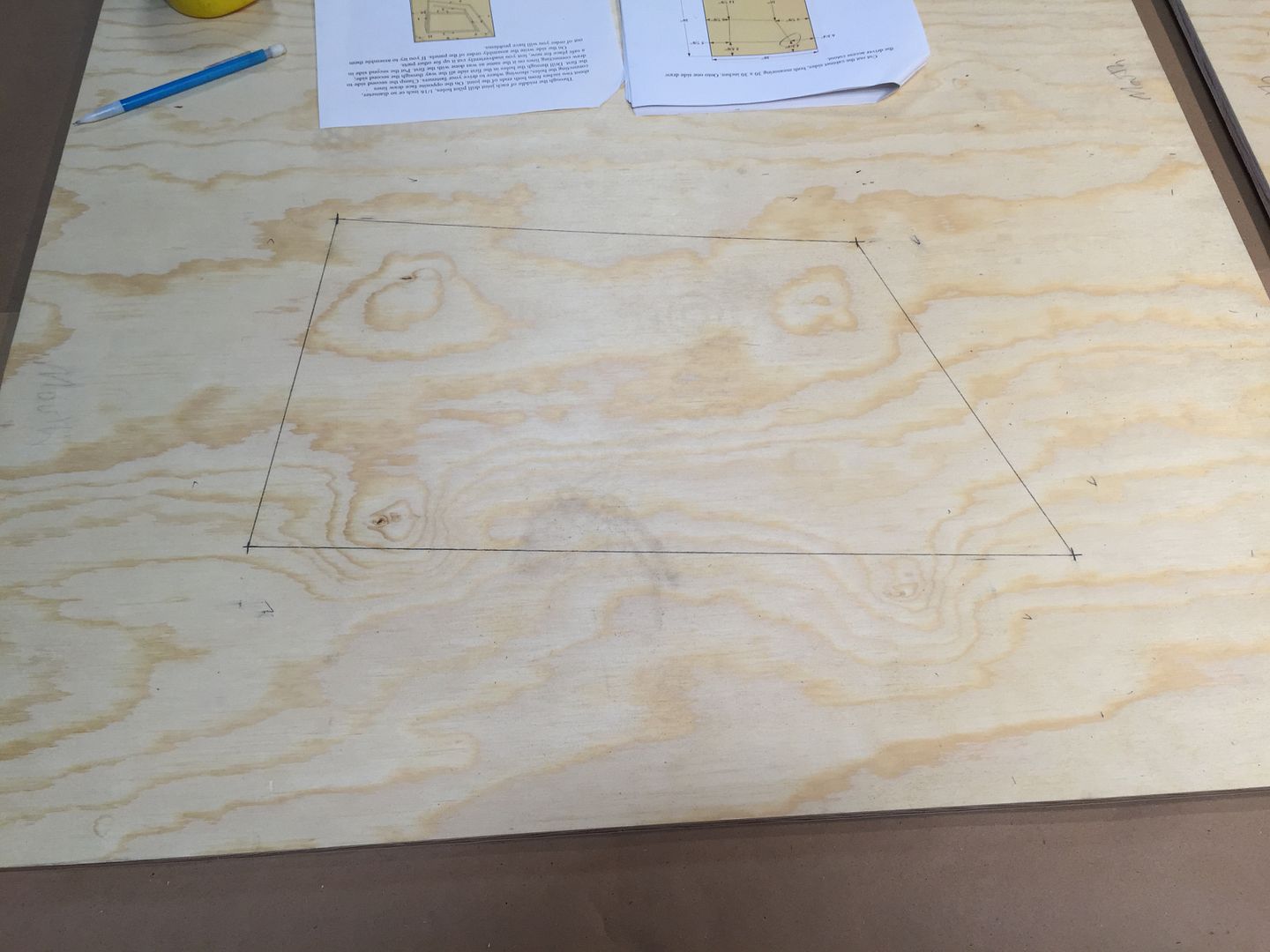

We took all the measurements from the build directions from Bill and over sized them for a rough cut and started ripping away!

And then allowed the rough panels to sit and placed some weight on top.

Meanwhile, we hooked up a signal generator and started the break-in process, and let it go for 48 hours.

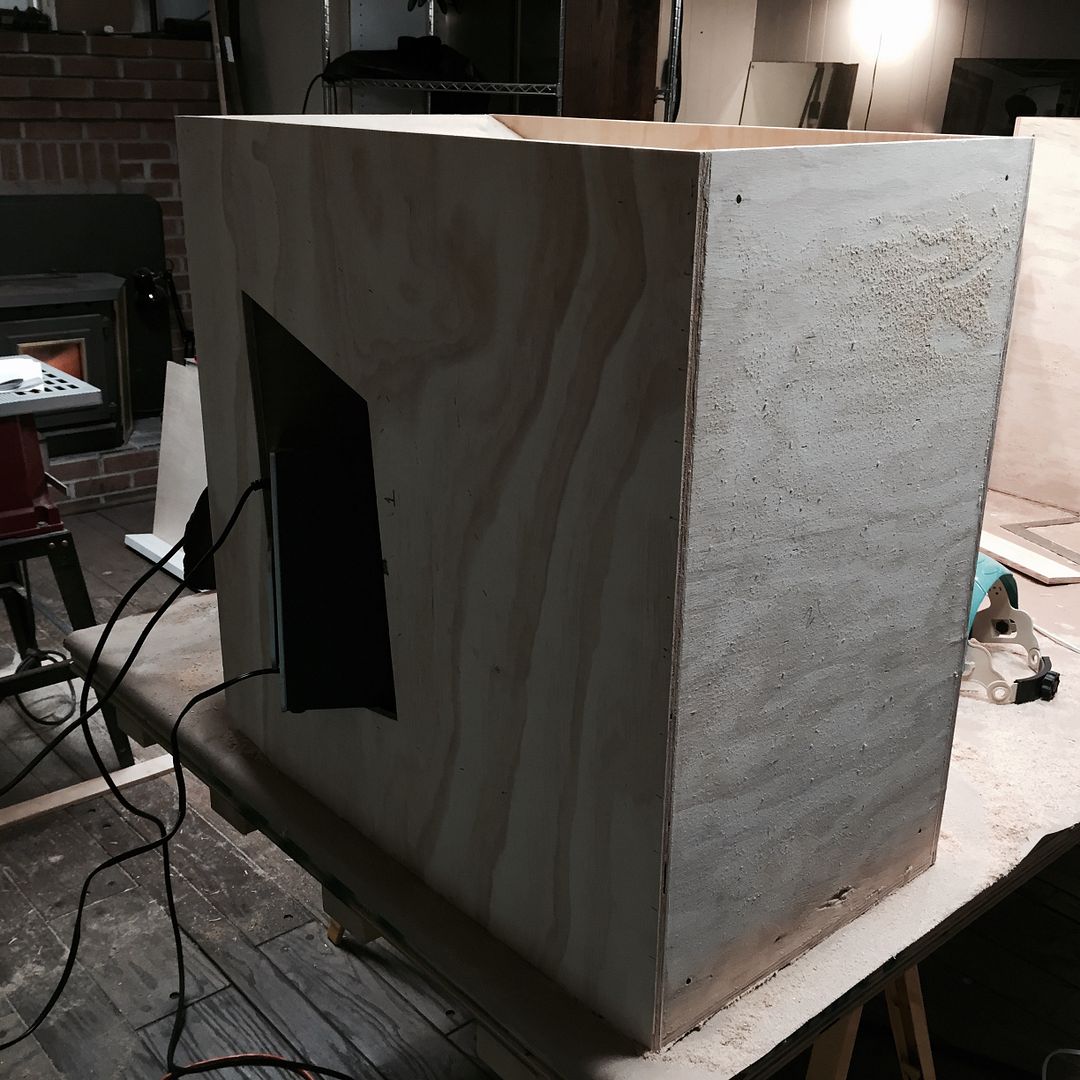

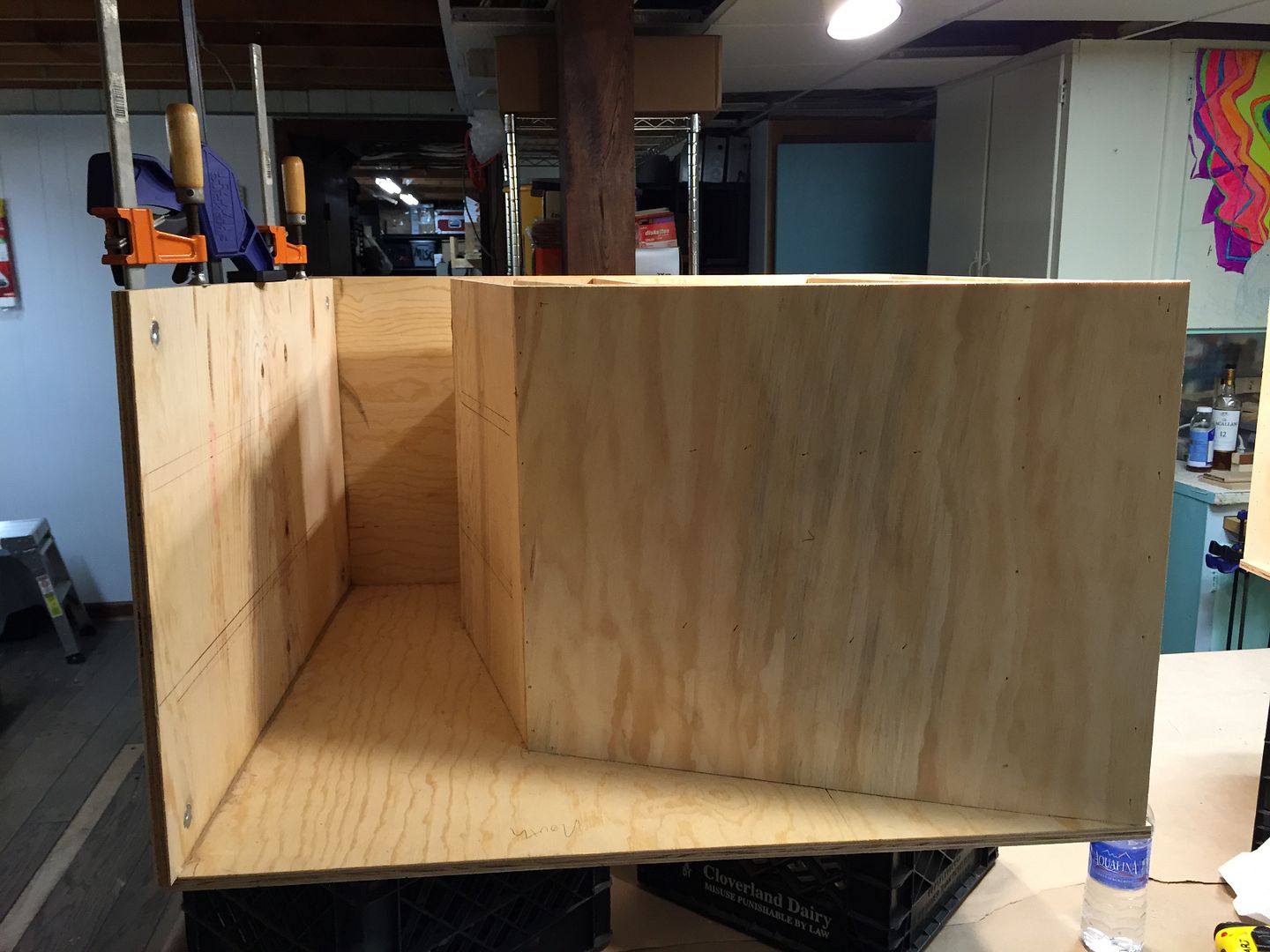

So after a LONG break, a few moves later, I was FINALLY able to get back on this. I didn't take any pics while we went though every piece and final cut all the panels and braces, again leaving some over sized, the build process had commenced!

Here is Jim using the router table to make some cirlces..

PERFECT!

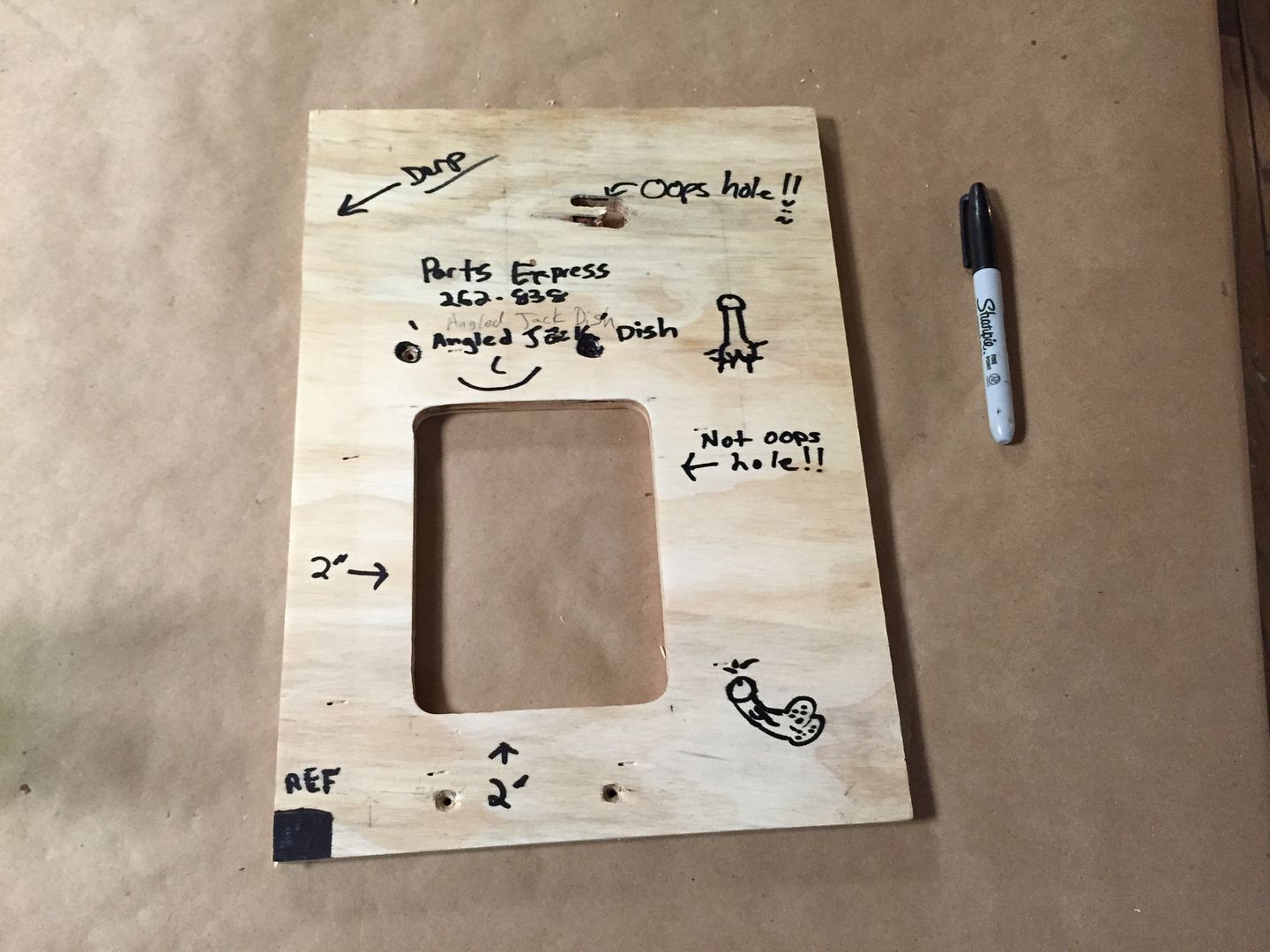

Using the mill to make a template for the jack plates. Jim makes it look SOO damn easy! It was early in the night, we do NOT use machinery while intoxicated!!

Of course we plan to build more, so make sure to mark your "wood", I mean.. template!

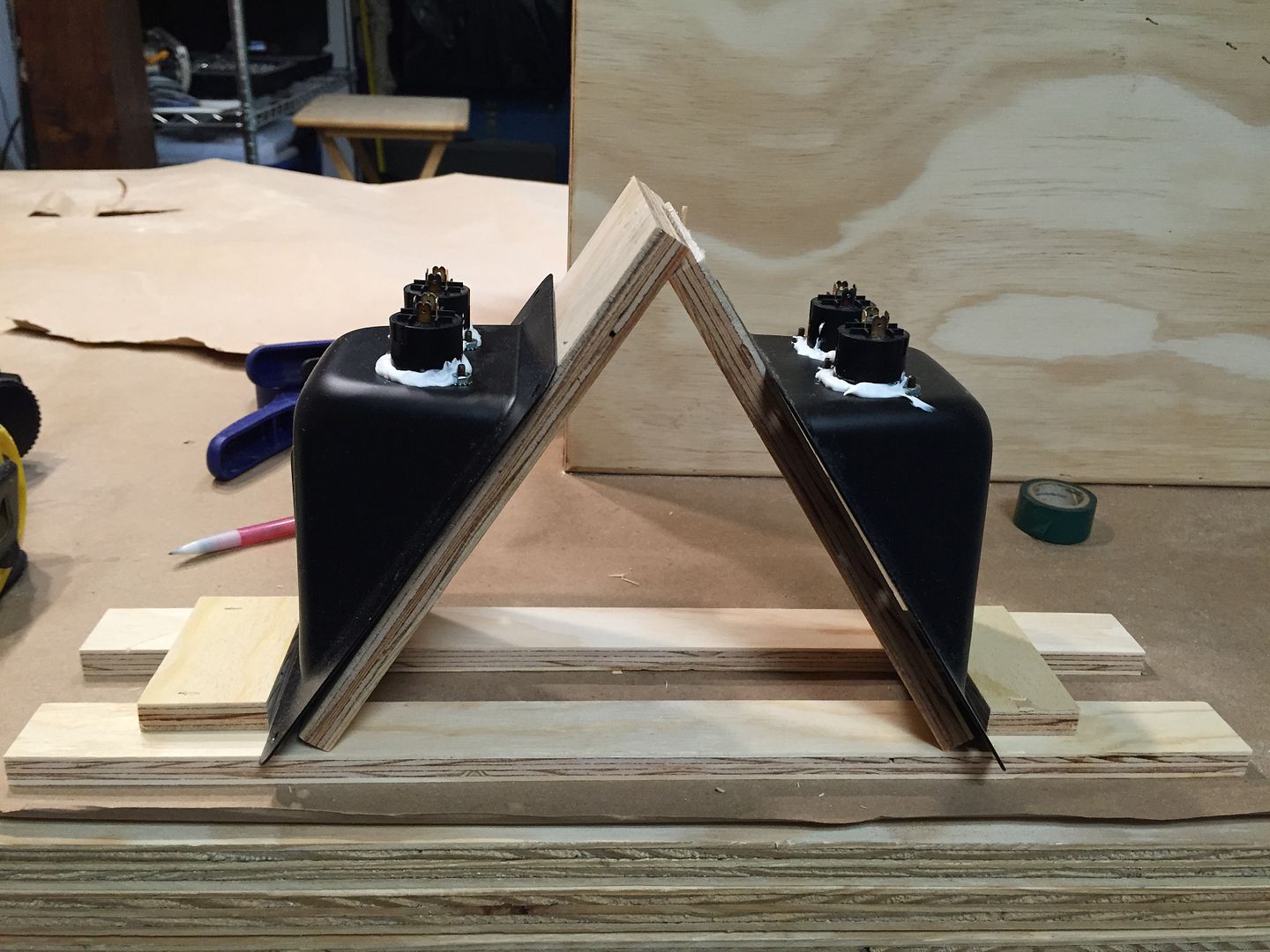

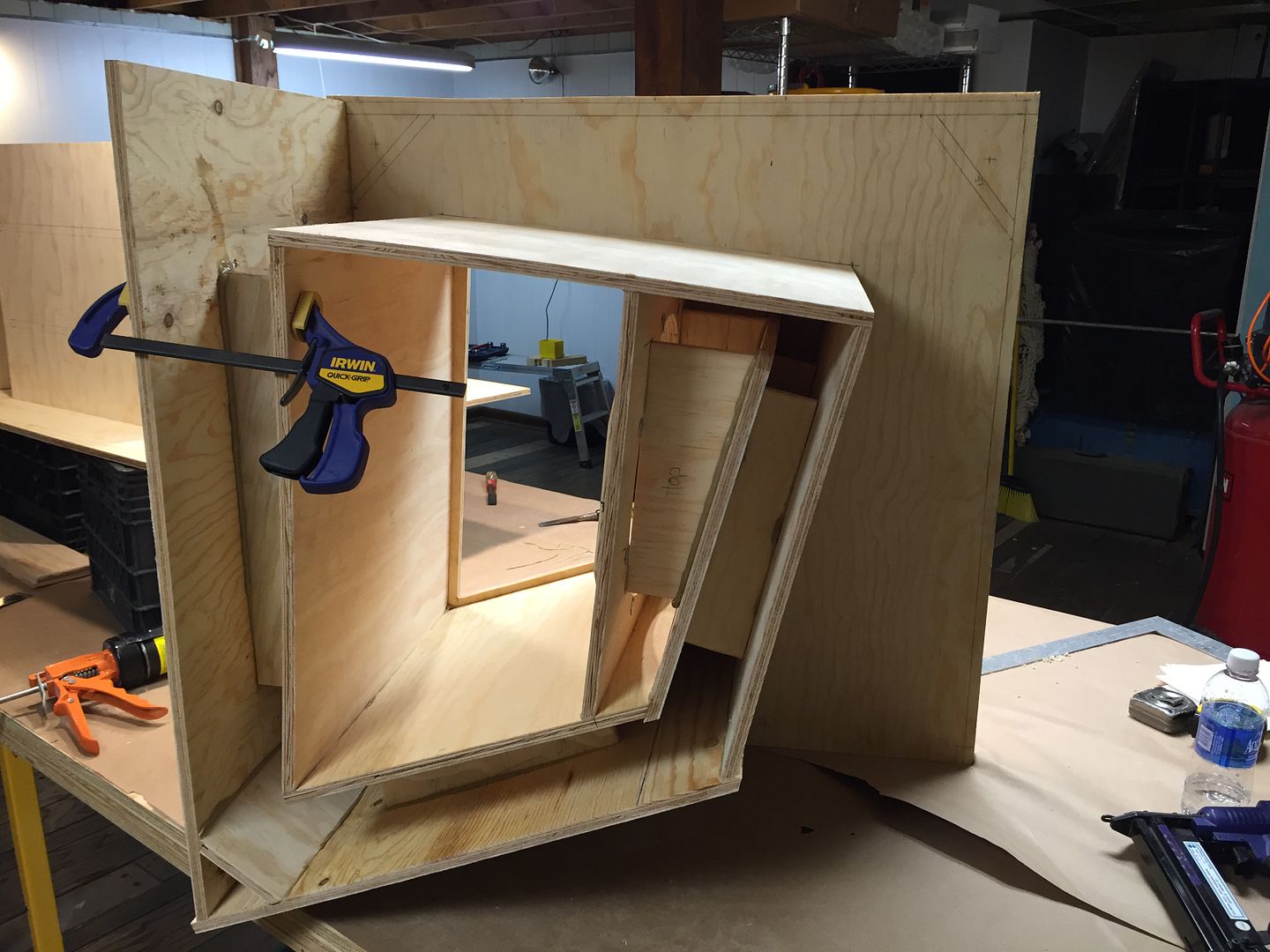

Lets make some snails!:

Simple... right? lol

Spooge!!

Bill, THANK YOU FOR THESE PLANS!!!

On to the build:

Step one... research, Research, RESEARCH and cutlist, Cutlist, CUTLIST! I decided to make mine 18" wide so I could transport them in my small SUV to gigs. And I settled on the Eminence Kappalite 3012LF. We also built my cabs mirrored so the access panels are always up or out.

We took all the measurements from the build directions from Bill and over sized them for a rough cut and started ripping away!

And then allowed the rough panels to sit and placed some weight on top.

Meanwhile, we hooked up a signal generator and started the break-in process, and let it go for 48 hours.

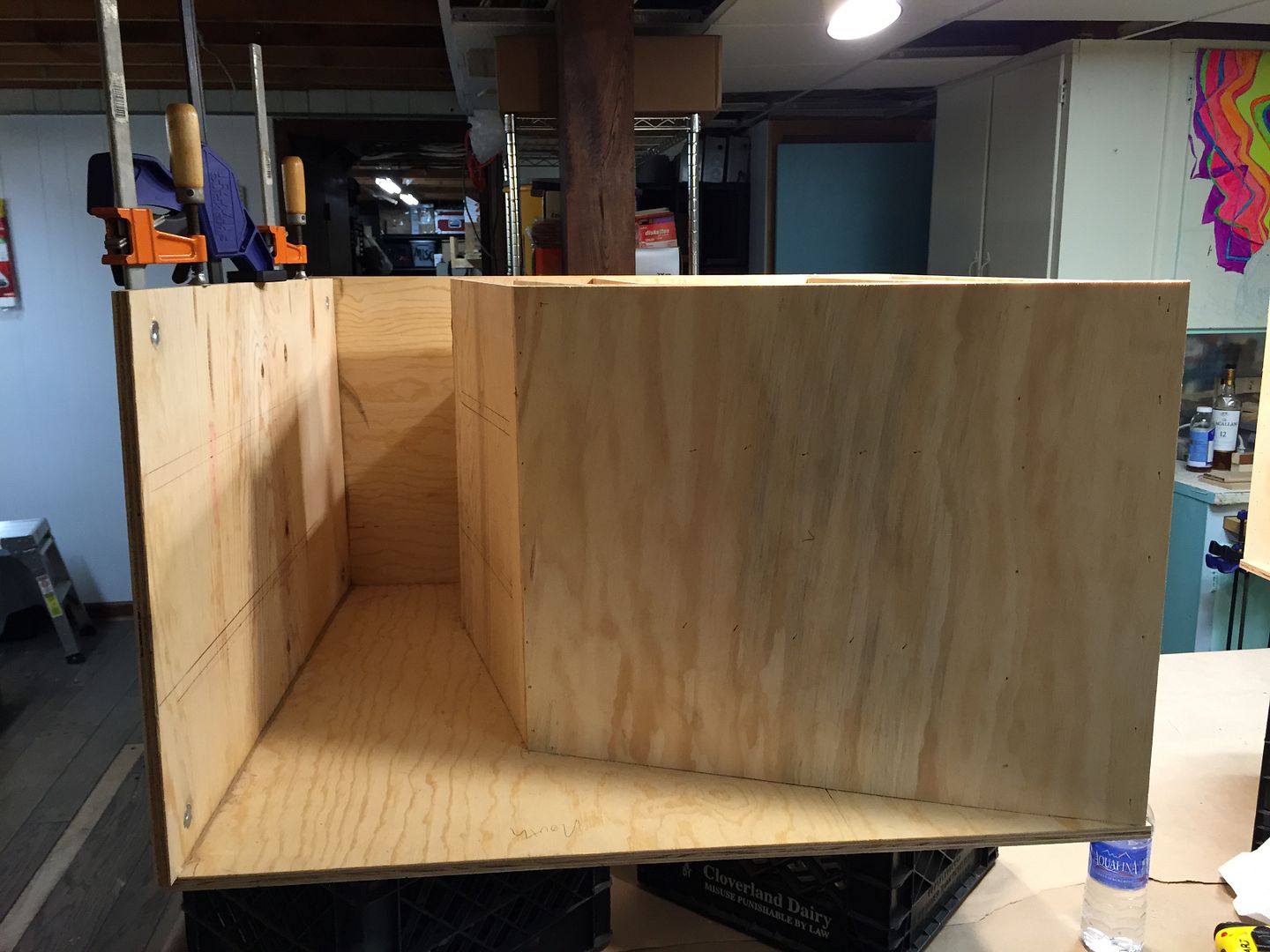

So after a LONG break, a few moves later, I was FINALLY able to get back on this. I didn't take any pics while we went though every piece and final cut all the panels and braces, again leaving some over sized, the build process had commenced!

Here is Jim using the router table to make some cirlces..

PERFECT!

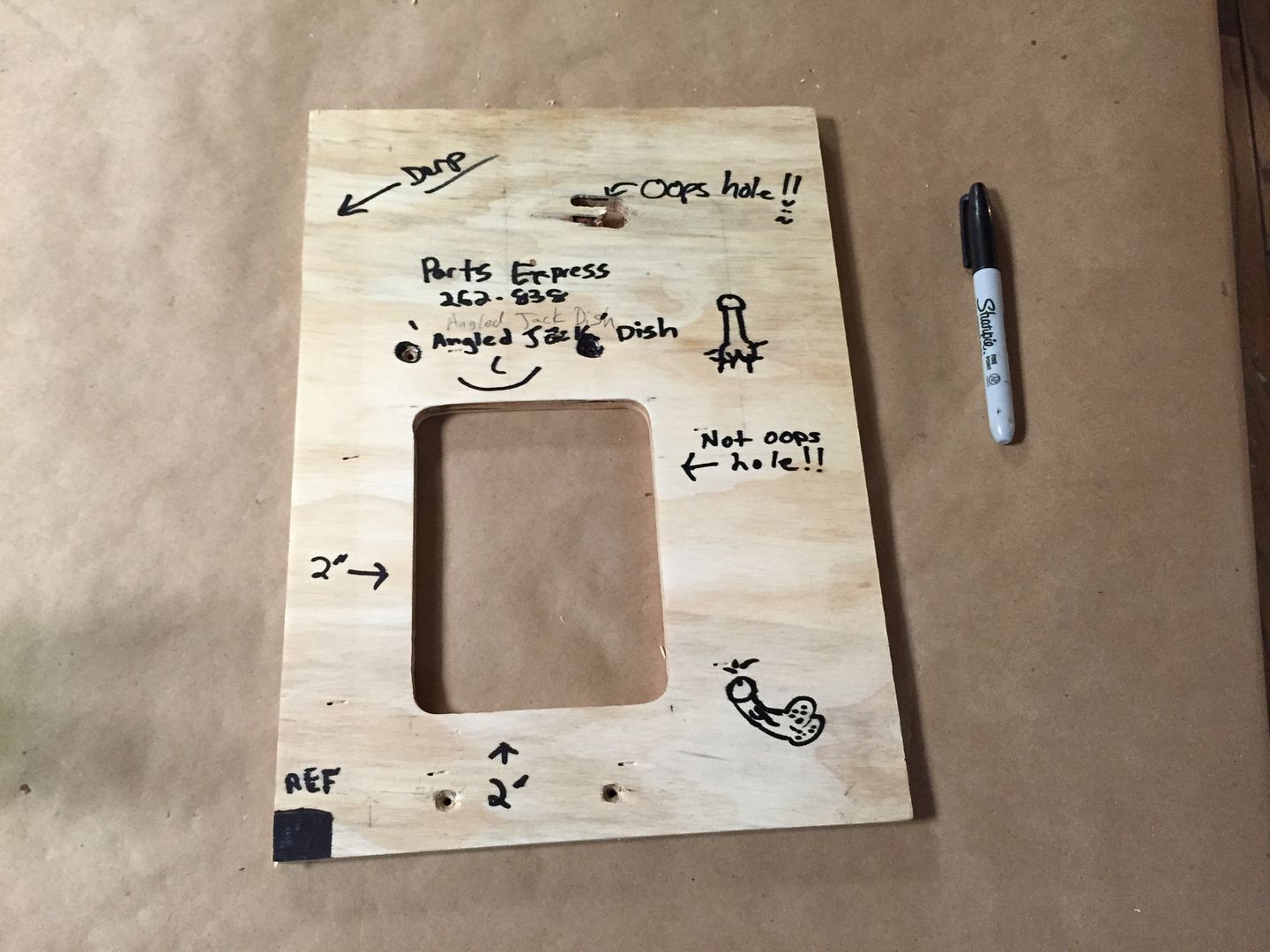

Using the mill to make a template for the jack plates. Jim makes it look SOO damn easy! It was early in the night, we do NOT use machinery while intoxicated!!

Of course we plan to build more, so make sure to mark your "wood", I mean.. template!

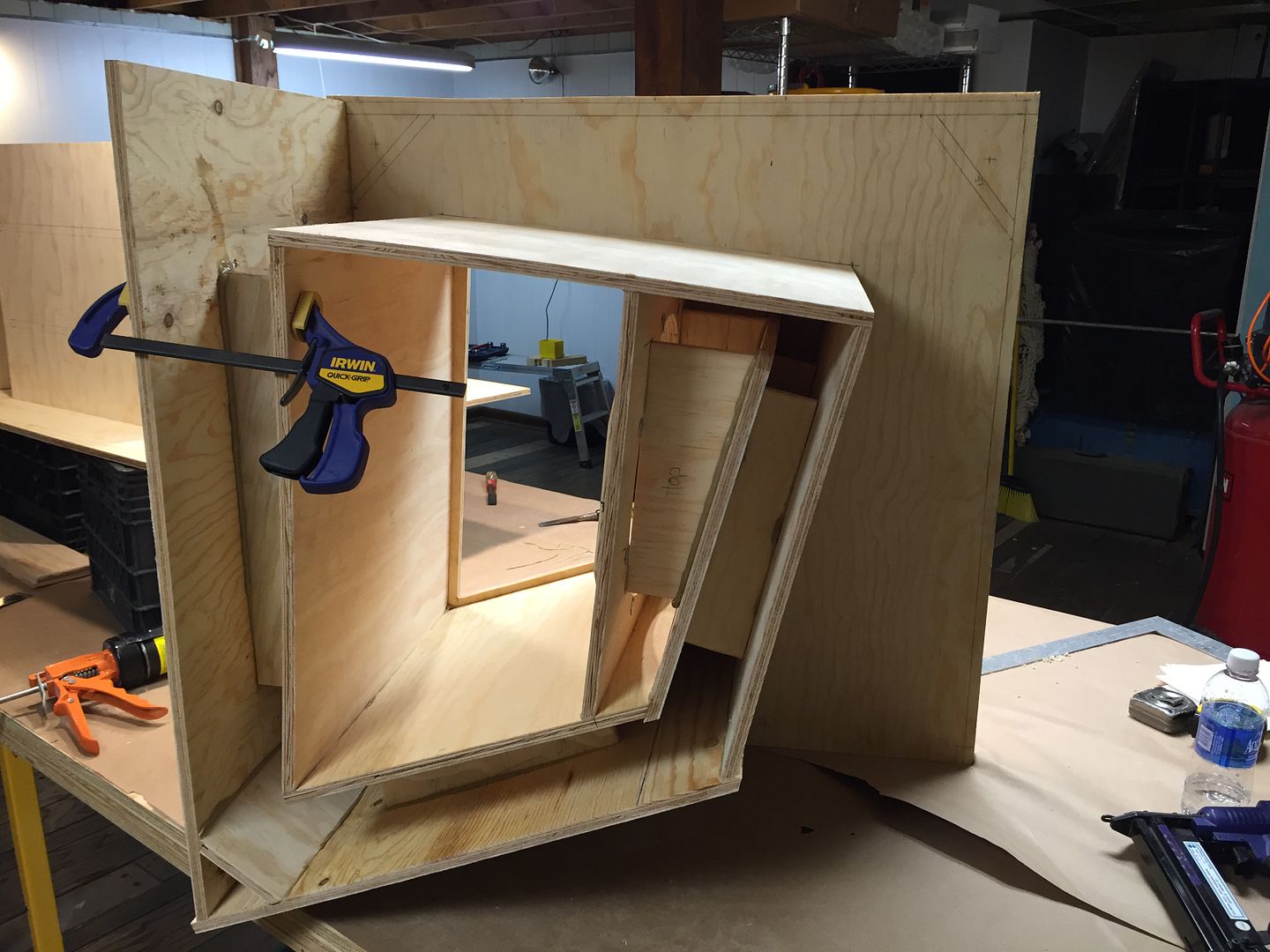

Lets make some snails!:

Simple... right? lol

Spooge!!