Page 1 of 2

2- 2x10 T30s

Posted: Sat May 17, 2014 11:09 am

by 67baja

Okay started building for the raft float party. I am using these Eminence 10" drivers:

•RE 2.34 ohms

•LE 1.36 mH

•QMS 10.51

•QES 0.34

•QTS 0.33

•Xmax 11.90 mm

•RMS 250 watts

•BL 11.23 Tm

•FS 28.1 Hz

•Mms 102.5 grams

•Mmd 99.0 grams

•Cms 0.312 mm/N

•Vas 49.6 liters

•SD 334.5 cm^2

•VD 398.1 cm^3

•Magnet Weight 67 ounces

•SPL 87.0 db 1W-1m

Of note to me are the VD of 398, xmax of 11.9 mm, FS of 28 HZ, and 4 ohm impedance. They have high xmax and vd for 10 inchers, and a low FS so I will install the reducer panels from the plans for use when LAB 12s are used. I am building 2x10 boxes so I can wire the drivers in series for an 8 ohm cabinet (10 ohm in horn).

The panels are 23 3/4" (long boring story about that). I am using pocket screws on this build, a first for me. So far I am a big fan of them. Pics to follow.

Re: 2- 2x10 T30s

Posted: Sat May 17, 2014 11:17 am

by 67baja

Here is the Kreg pocket screw jig I am using:

[/URL]

Panel 1 and 2 showing the pocket screws

[/URL]

[/URL]

Baffle with pocket screw cutouts:

[/URL]

For my driver spacer, I went with an almost full double baffle. I screwed the 2 together, routed the 1" thick baffle holes, then glued the 2 together and clamped them.

[/URL]

[/URL]

[/URL]

Re: 2- 2x10 T30s

Posted: Sat May 17, 2014 12:43 pm

by Hackomatic

Very nice!

What's the model of that Kreg unit?

Re: 2- 2x10 T30s

Posted: Sat May 17, 2014 1:24 pm

by 67baja

Hackomatic wrote:Very nice!

What's the model of that Kreg unit?

I don't remember what model it is, but came in the best kit Lowe's and Home Depot stocks.

http://www.lowes.com/pd_3526-39450-K4MS ... facetInfo=

My wife thinks I need to build us a bed so I bought the pocket screw kit supposedly for the bed.

What I have noticed about the pocket screws is it is way easier to use them than to predrill a bunch of holes and then screw the panels down from the bottom side of the box. Also, the pocket screws tend to push the panel about 1/16" so I have to compensate for that when I position the panels.

Re: 2- 2x10 T30s

Posted: Sat May 17, 2014 3:59 pm

by Harley

67baja wrote:My wife thinks I need to build us a bed so I bought the pocket screw kit supposedly for the bed.

She doesn't get on the internet at all ???

Re: 2- 2x10 T30s

Posted: Sat May 17, 2014 7:19 pm

by dswpro

I was all about pocket screws until I started a T39 and saw how strong the PL glue is.

Since then I've never bothered. I use a 1.5 inch electric brad nail gun and good amounts of PL.

I use the brad nail gun to set temporary bracing, build jigs, even tack down wood I'm cutting or routing.

Looks like you are having fun though. Keep up the good work!

Re: 2- 2x10 T30s

Posted: Sun May 18, 2014 5:54 am

by LelandCrooks

I still find pocket screws advantageous. Especially if you're doing a bunch of cabs. Easy way to fix the walk is toenail the panel with 23ga pins. Even on a big panel a couple will do it.

Re: 2- 2x10 T30s

Posted: Sun May 18, 2014 11:28 am

by 67baja

I have a pneumatic stapler and 18 gauge brad nailer that helps a lot for braces and I have build cabs almost completely with them, but I like to use screws to really pull everything together tight. Leland, what length pins do you use? I may have to get me a pin nailer now.

Re: 2- 2x10 T30s

Posted: Sun May 18, 2014 2:43 pm

by 67baja

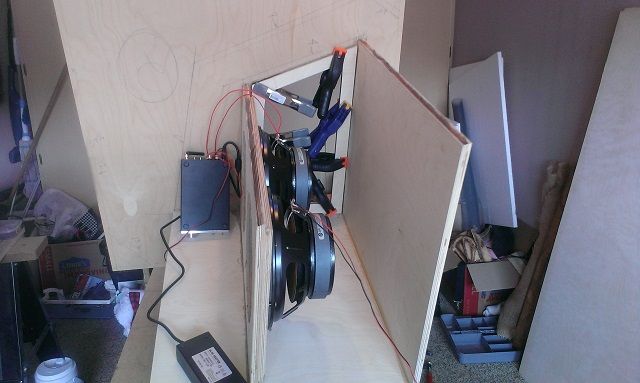

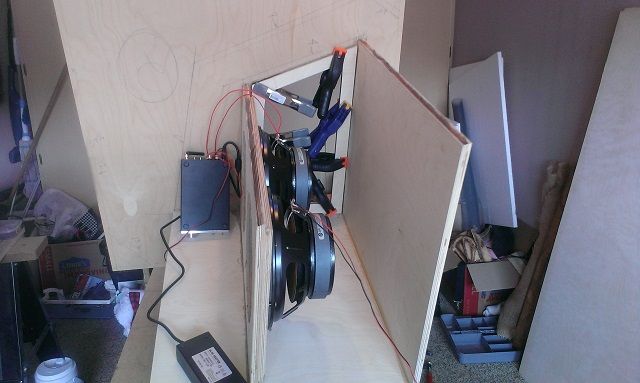

I decided to use 1 piece access cover flanges on these - I hate making the flanges at the end of the build. Both panel 3's are installed with the drivers mounted and drivers are now being broke in using a tone generator and a small amp. The flanges are installed in cab #1 and will be installed in #2 after the drivers are broke in.

Note I will be leaving the drivers mounted through out the build, since I don't want to take them out and reinstall later when it is more difficult. The driver chamber will be vacuumed out before installing the last side. Pics will be posted later. Time to go cut some more wood in the 100 degrees drive way now.

Re: 2- 2x10 T30s

Posted: Mon May 19, 2014 7:06 am

by LelandCrooks

3/4. 1" which I use for construction will sometimes pierce the face if you're not careful.

A pin nailer was one of the best tool investments I ever made.

Re: 2- 2x10 T30s

Posted: Wed May 21, 2014 3:19 pm

by miked

I bought a Kreg Jig AFTER I'd already built 4 OTops and 4 T48s. I used the Kreg on a couple of basic woodworking projects, and I can say I absolutely wish I'd known about the Kreg jig sooner! It would've made things so much easier! I would've had almost zero screw holes to fill afterwards, no brad nails missing the panel and shooting all over the place, etc.

Why is it that after you've FINISHED your cabs, you now know 5 different ways to do everything BETTER AND FASTER?

Re: 2- 2x10 T30s

Posted: Wed May 21, 2014 3:21 pm

by miked

Oh yeah: "Raft float party."

So...these cabs or going on a raft or a pontoon boat of some kind? I hear "raft" and I think of $5 inflatable jobbie that you float on in a backyard pool. What's the rest of the system like? Gotta have tops of some kind.

Re: 2- 2x10 T30s

Posted: Wed May 21, 2014 3:49 pm

by 67baja

As of now, sound will be from phone or Ipod plugged into my Pioneer mixer, 2 Otop12s driven off a QSC USA400 amp (110 watts x 2 at 8 ohm, 200 x2 at 4 ohm), a Driverack PA+, and I just ordered a Peavey IPR2 3000 to drive the 2 - 2x10 T30s. I wish I had time to build 2 more 2x10 t30s. I also ordered parts for SLA Pros, so if I get the chance I may build the Pros and face them toward the back of the raft. The raft itself is 8'x16' build out of pressure treated 2x6s. Plastic 55 gallon barrels will be the "floats" for the raft.

There is a "best raft" contest so we will dress up the float with palapa umbrellas, plus have a margarita machine and 500 bead necklaces to give away to the ladies that are 'adventurous'

Re: 2- 2x10 T30s

Posted: Wed May 21, 2014 4:20 pm

by 67baja

Some pics from earlier in the week. Oh, sorry about the crappy cell phone pics. Hopefully these will show someone an idea or 2 on building BFM cabs.

Baffle and drivers installed, and breaking in the drivers with an Ipad and Lepai (allegedly) 200 watt amp.

Traced out my access panel, added a 1/2" around the outside, and about 3/4" on the inside:

And installed the piece here:

After the PL started setting up, but not fully cured, I used a chisel and removed the squeeze out so the access panel will fit perfectly.

Cab #2 - you can see I labeled the parts 2-3 meaning cab 2, panel 3.

And Cab #1

Brace between the drivers on the baffle

Cab 1, panel 5

[URL=

http://s269.photobucket.com/user/67baja ... 7.jpg.html]

And panel 2 getting the access panel flange

Re: 2- 2x10 T30s

Posted: Wed May 21, 2014 6:16 pm

by Bruce Weldy

Tape a piece of cardboard over those drivers! You're scaring the hell out of me. And a plastic bag taped over the backside too.

Then take the cardboard off right before putting on the second side. But, leave the plastic bags on so PL doesn't drip on 'em.

That a real big chance you are taking leaving 'em in like that.

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]