Page 1 of 12

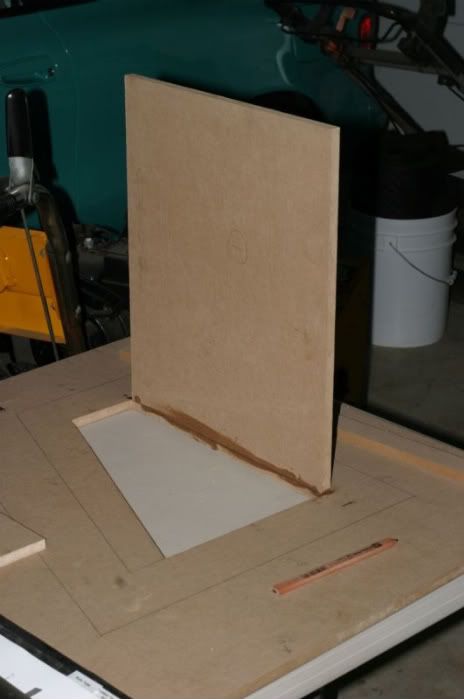

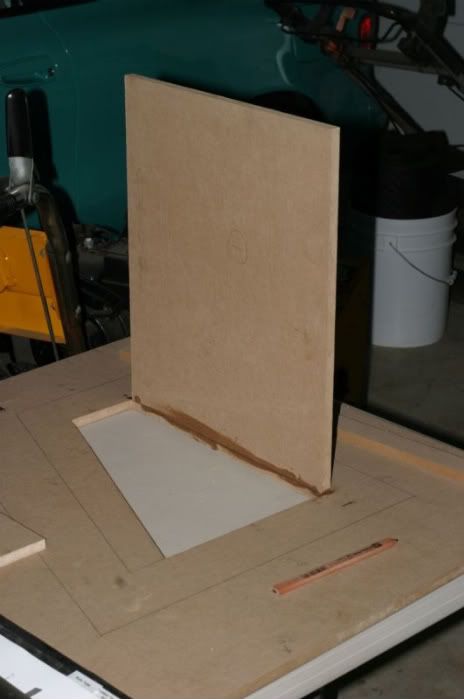

Table Tuba build!!

Posted: Wed Nov 03, 2010 10:30 pm

by digital_chris

Re: Table Tuba build!!

Posted: Wed Nov 03, 2010 10:54 pm

by Radian

When it's complete, you'll have to report back whether the cab vibrates any at full tilt with the MDF and all.

How well does the PL seem to work on it?

Careful when drilling around the baffle for the driver mounting screws, don't want that stuff to crumble out on ya.

Other than that, looks like fun!

It's going to get heavy in a

hurry!

Re: Table Tuba build!!

Posted: Wed Nov 03, 2010 11:47 pm

by Tom Smit

Happy building!

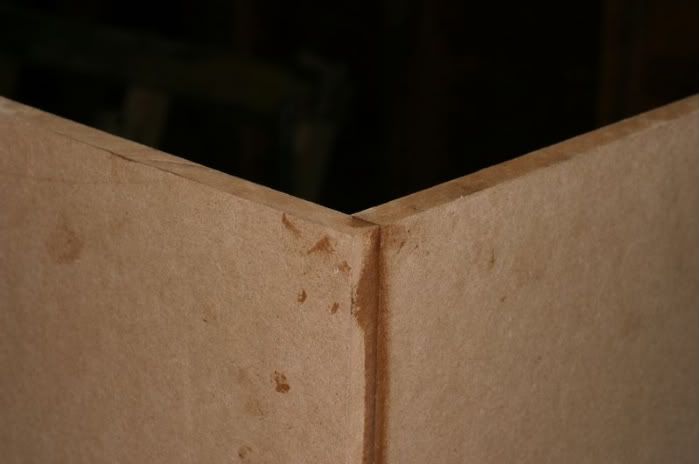

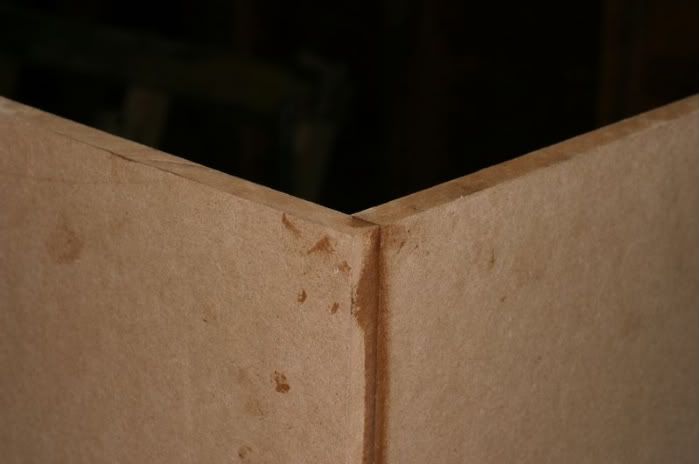

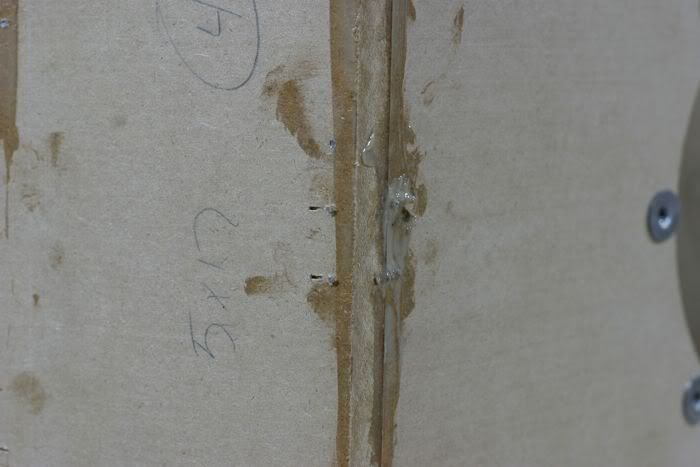

About the PL, just let it squeeze out along the panel edge and harden (don't need to remove or spread). On the exterior you can use a chisel or flush bit to remove once it's hardened.

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 12:20 am

by digital_chris

Radian wrote:When it's complete, you'll have to report back whether the cab vibrates any at full tilt with the MDF and all.

How well does the PL seem to work on it?

Careful when drilling around the baffle for the driver mounting screws, don't want that stuff to crumble out on ya.

Other than that, looks like fun!

It's going to get heavy in a

hurry!

Now don't go getting a brotha all worried that his project will crumble beneath him

I will let you know how it does with the MDF. The plans mentioned it could be used. I wanted to use baltic birch, but chose MDF for a few reasons. One being that BB is hard to find around me and I didn't have too much luck in my search. It's also more expensive than MDF and with this being my first build, I'd rather screw up a piece of MDF rather than a piece of BB, and last, the MDF is REALLY flat compared to other types of plywood that was available to me.

If this project goes well, the future boxes will definitely be from baltic

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 1:27 am

by SeisTres

MDF does ok for house stuff, but that's about it, but as it is a TT, no worries there. HOWEVER, if it was me, I would either 1) use tnut/hurricane nuts or 2) attach the driver on a spacer made of hardwood and glue that to the mdf. My mdf would want to crumble whenever I was building the thing and I just wouldn't trust it at all with the single 1/2" to hold the driver with wood screws.

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 7:54 am

by psg

How about constructing a ring made of plywood, glue it on the opposite side to the driver and install T-nuts into that plywood?

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 1:12 pm

by SeisTres

psg wrote:How about constructing a ring made of plywood, glue it on the opposite side to the driver and install T-nuts into that plywood?

Then it'll mess up the horn dimension. If using t nuts no need for the ring. The ring is really if he's just going to go with wood screws.

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 1:49 pm

by psg

Then it'll mess up the horn dimension

Only by the volume of the ring...

If using t nuts no need for the ring. The ring is really if he's just going to go with wood screws.

Now I'm confused. In your previous post you worried about MDF crumbling...

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 3:41 pm

by SeisTres

psg wrote:Then it'll mess up the horn dimension

Only by the volume of the ring...

If using t nuts no need for the ring. The ring is really if he's just going to go with wood screws.

Now I'm confused. In your previous post you worried about MDF crumbling...

Well, I take that back, it's not really the volume the ring will take up as the braces are about equal, but it will be another 1/2" which will run

perpendicular the horn path, thus blocking the waves.

Reread my post, if using the hurricane nuts and he's careful, the mdf will be fine. My recommendation on the ring was if he was going with wood screws (for the driver).

However, looking at the pics, it looks like he went with a deeper driver (can't tell if that's teh mcm 8" or not) so the ring might not even be a real tight fit.

Re: Table Tuba build!!

Posted: Thu Nov 04, 2010 4:16 pm

by digital_chris

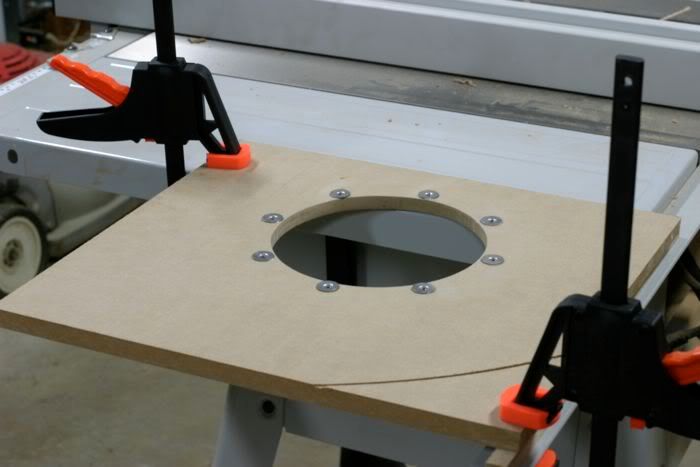

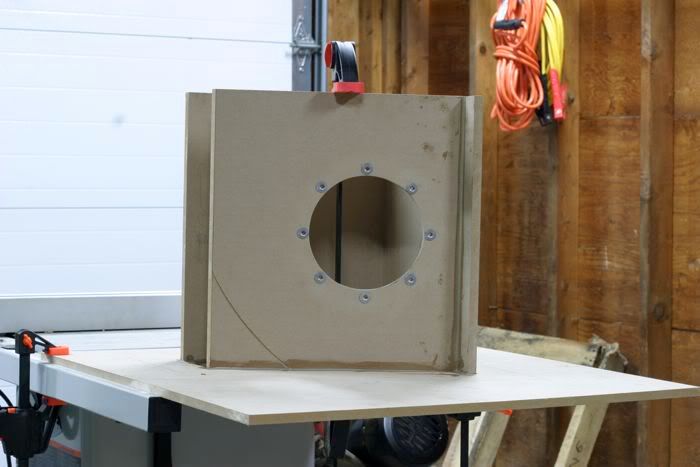

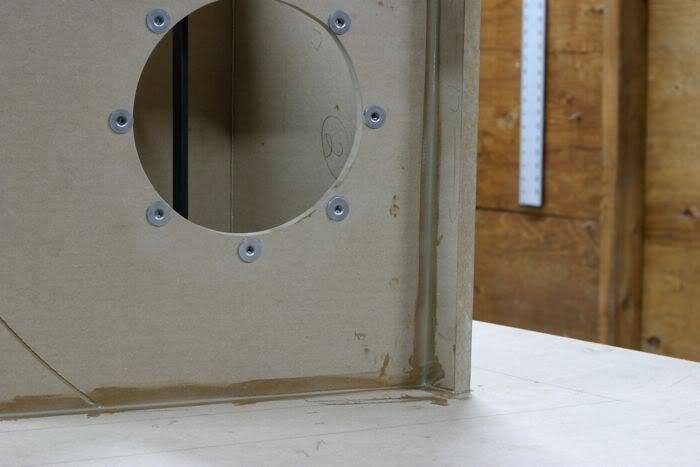

It is actually the Dayton DCS205-4, the alternative to the MCM because the MCM was not going to be available for a while. I'm not too worried about the MDF though, the hurricane nuts I will be using will be close to the edge of the baffle hole but I shouldn't have to much of a problem with it

Re: Table Tuba build!!

Posted: Sat Nov 06, 2010 12:52 pm

by bossman

Your Table Tuba looks pretty good so far. That thing is going to weigh a ton!

Keep us updated.

Re: Table Tuba build!!

Posted: Sat Nov 06, 2010 10:37 pm

by digital_chris

Re: Table Tuba build!!

Posted: Sat Nov 06, 2010 10:47 pm

by Radian

Looks good so far

...I had the same issue with the brads 'cept I was using ACX, and they'd hit a knot or deflect off a ply, then blow out the side of the panel. Comes with the turf I guess.

Before you get any further, right now would be a good time to make sure that beautiful driver actually bolts up nicely to those H-nuts. If you already have checked for this, then disregard, but better to figure out now if there might be any issue than later. Dry fitting of parts in advance helps avoid nasty surprises.

Sweet air compressor BTY...

drool

-Radian

Re: Table Tuba build!!

Posted: Sun Nov 07, 2010 12:43 am

by SeisTres

Yeah, I fit the driver even BEFORE gluing anything at all. If it does fit, a new baffle is the solution, luckily, I've never had to replace one.

And don't worry about the weight, as it will be no heavier than BB, so no biggie there.

Re: Table Tuba build!!

Posted: Sun Nov 07, 2010 2:34 am

by digital_chris

Radian wrote:Looks good so far

...I had the same issue with the brads 'cept I was using ACX, and they'd hit a knot or deflect off a ply, then blow out the side of the panel. Comes with the turf I guess.

Before you get any further, right now would be a good time to make sure that beautiful driver actually bolts up nicely to those H-nuts. If you already have checked for this, then disregard, but better to figure out now if there might be any issue than later. Dry fitting of parts in advance helps avoid nasty surprises.

Sweet air compressor BTY...

drool

-Radian

Lol, thanks for the props on the compressor Radian

I did test fit the driver after installing 7 or the H-nuts. Why 7? because I forgot to drill out the 8th hole so I figured I'd get the 7 glued in, mount the driver and then mark where the 8th will go. Worked out fine, I think

I didn't test fit the driver in there after I installed the 8th H-nut, I'm sure it will be fine

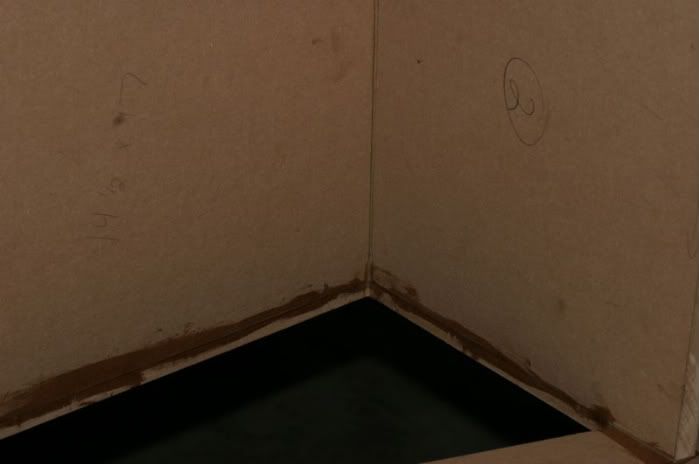

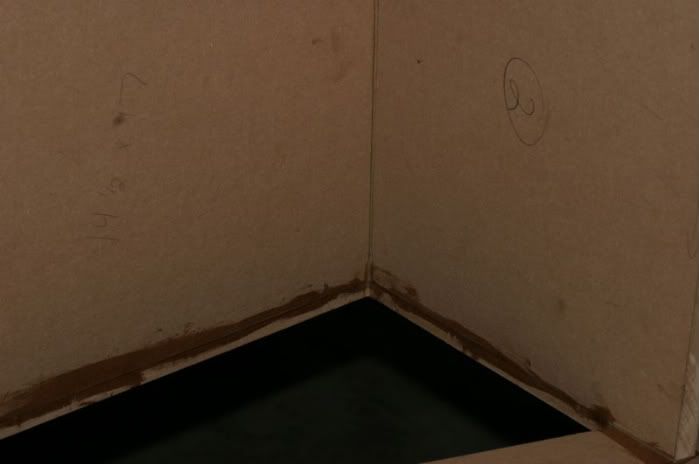

I just installed panel 5 and made the brace for 3/5. MY GOSH was the panel a pain. I cut my first one too short, dummy me, so I had to make a new one. The whole process took almost an hour and a half. For some reason, the panel wouldn't sit flat on the bottom board so there is a tiny gap, I will show in pictures tomorrow. I had to cut the angles many times and trim to fit a few times until I got it close enough. Then I applied PL, and brads, again, problems with the brads. I SUCK at nailing, ughhh, the 2nd worst part of the build, first the PL and then the brads. All of this hassle almost makes me NOT want to build my THTLP