Page 5 of 31

Re: myn's Tuba HT Build Thread

Posted: Tue Jun 30, 2009 9:34 pm

by myn

Re: myn's Tuba HT Build Thread

Posted: Tue Jun 30, 2009 9:42 pm

by WB

myn wrote:

Also a quick tip I thought I'd share. For slow asses like myself that only use a bit of PL every other day, the way I preserve it is by using a spare Nitrile glove an elastic band. Not sure how everyone else does it but this method seems to work for me.

I stick a medium length wood screw in the nozzle.

Re: myn's Tuba HT Build Thread

Posted: Tue Jun 30, 2009 11:35 pm

by Scott Brochu

16 penny nail for me

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 7:13 am

by WB

I like the screw because the the PL hardens on the threads and pulls out like a custom fit plug. It leaves a clean nozzle ready to use. Never used a nail before, might act the same way though.

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 7:20 am

by Scott Brochu

WB wrote:I like the screw because the the PL hardens on the threads and pulls out like a custom fit plug. It leaves a clean nozzle ready to use. Never used a nail before, might act the same way though.

I might try that way next time if I can remember.

What size screw do you use? 3" wood screw?

How big do you clip your tube tip?

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 7:20 am

by Bill Fitzmaurice

I use a cheap phillips screwdriver, periodically removing dried PL with pliers.

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 8:09 am

by David Carter

Scott Brochu wrote:WB wrote:I like the screw because the the PL hardens on the threads and pulls out like a custom fit plug. It leaves a clean nozzle ready to use. Never used a nail before, might act the same way though.

I might try that way next time if I can remember.

What size screw do you use? 3" wood screw?

How big do you clip your tube tip?

3 1/2" decking screw. Clip the tube just big enough for the screw to fit snugly through the hole.

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 9:21 pm

by myn

[== 7/1/2009 ==]

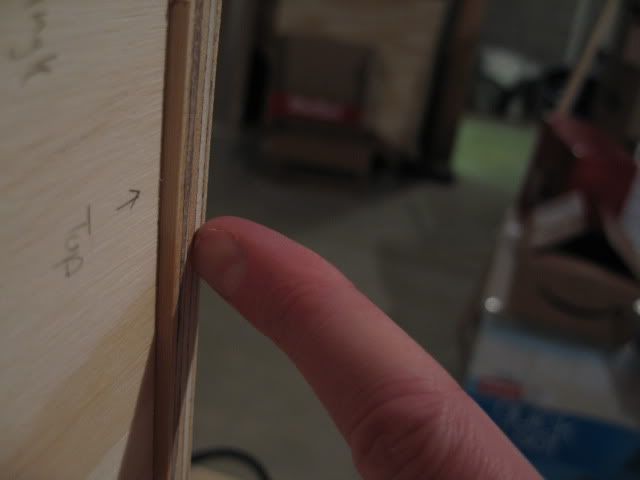

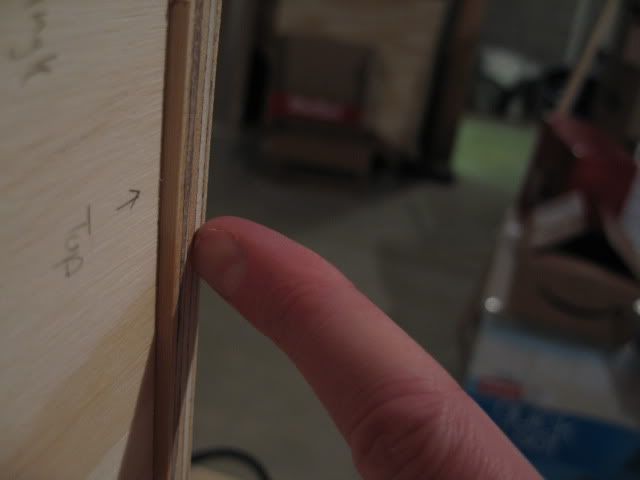

I did some test fitting today on Panel 4 today. It appears some of my Araucoply panels are warped. I am not sure if it was because I was storing it vertical or what. In any case the result of the test fitting is below. I have since stored them in a horizontal orientation.

Looks like I'll be making use of some guideboards screwed to the face to see if I can straighten it out enough where I can secure it to the adjacent panels.

Any other tips on getting these unwarped??

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 9:29 pm

by DJPhatman

myn, what are you using to hold the panels together while the PL cures?

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 9:30 pm

by Bill Fitzmaurice

An eighth inch of warping won't bother fifteen to seventy five foot wavelengths all that much.

If they bother you use a guideboard to pull them out until you fasten the joint.

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 10:06 pm

by maxmercy

Had the same thing happen with my BB ply. Just clamp a straight board to the panel as the PL cures, or before you nail/screw it in place...

Looking good. Looks like you are taking your time and doing it right...don't rush. My THT and SLAs took over 7 months to finish....

JSS

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 10:10 pm

by myn

DJPhatman wrote:myn, what are you using to hold the panels together while the PL cures?

1) Line up the next panel using guideboards screwed into the side panel/vertical panels and a roofers triangle to ensure its square

2) clamp

3) predrill screw holes (I go about 3/8" into the piece I'm attaching)

4) unclamp

5) apply PL

6) Clamp

7) screw, making sure to hit the hole on the panel being attached

8) remove/unscrew guide boards (only because I want to reuse them and I want to wipe the PL off of them)

Am I doing something wrong?

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 10:13 pm

by myn

Bill Fitzmaurice wrote:An eighth inch of warping won't bother fifteen to seventy five foot wavelengths all that much.

If they bother you use a guideboard to pull them out until you fasten the joint.

What about that little edge? If it's not flush will this cause an issue?

I'm used to traditional alignments where the port path has to be really really smooth or port chuffing is heard.

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 10:32 pm

by maxmercy

That edge will cause no issue with the wavelengths concerned, as Bill mentioned. You are good. Your technique is sound as well. Only concern is any air leaks, but you have already said you caulk the joints, so you are good there as well...

JSS

Re: myn's Tuba HT Build Thread

Posted: Wed Jul 01, 2009 10:43 pm

by myn

maxmercy wrote:That edge will cause no issue with the wavelengths concerned, as Bill mentioned. You are good. Your technique is sound as well. Only concern is any air leaks, but you have already said you caulk the joints, so you are good there as well...

JSS

One thing I did do tonight was used a chisel in the interior where the driver sits and scraped off the overflow of PL as the flanges will need to sit flush against the surface. On the opposing side of the panels I caulked it along the edge. As much as I'd like to retain the overflow everywhere I think this is one case where overflow is a hindrance. I am suspecting you did the same thing?