… Such as this one on last Saturday (DR290s over LABhorns):

So, last week I got the Padded covers. The man took the liberty to change my design a little

but they turned out really nice and fit perfectly, easy to dress onto the wedges and wide Velcro closing on all edges:

Another view:

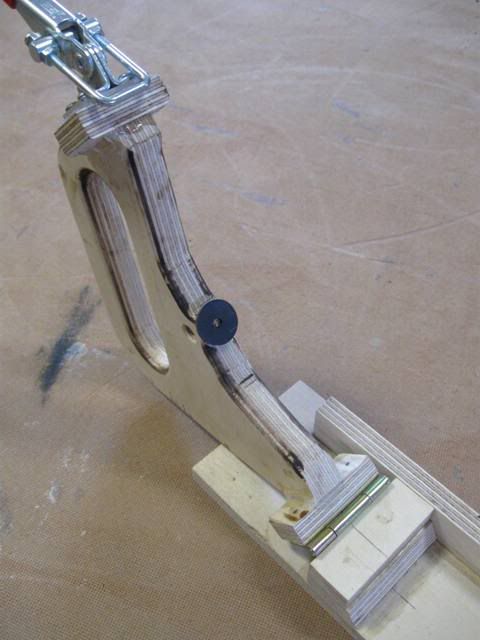

Yesterday and today I spent some time building a jig for cutting the piezos.

The Jig in open/empty position:

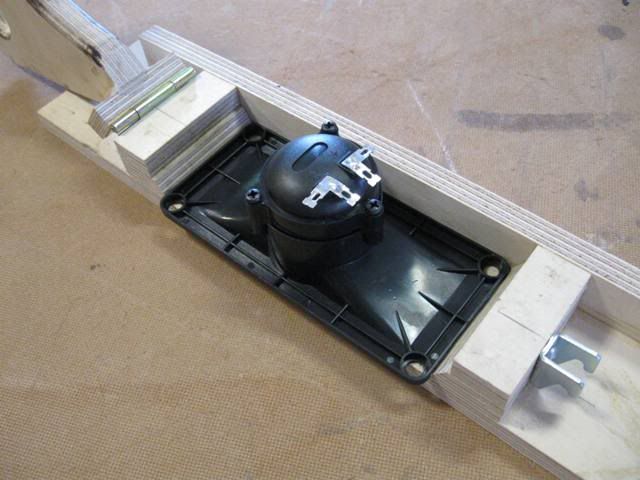

The 1016 piezo located inside the jig:

And here closed, clamped and ready for cutting:

This setup is for the array end piezos that are cut only on one side.

The rest will be trimmed on the other side also by rotating them and a spacer inserted into the jig.

Hopefully tomorrow…