I took a break to grab some lunch. Here's what I've done so far today:

Finished cutting all handholds and jackplate holes.

Cut one new back and one new bottom b/c apparently sometimes I can't read a ruler. Thankfully I had leftover pieces big enough.

Rounded over all handholds.

Have I mentioned I love routing templates? This one was easy to make since the cutout was rectangular. Just used the rising cut method on the TS. (Thanks, Bruce).

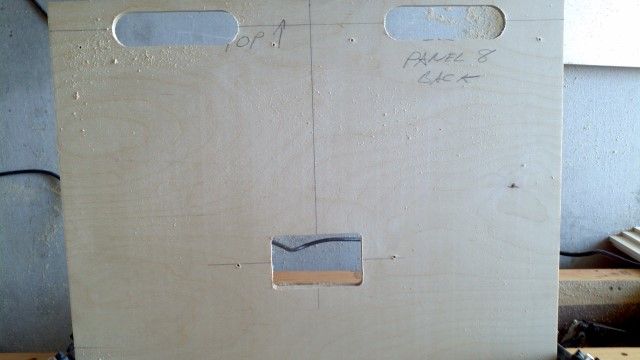

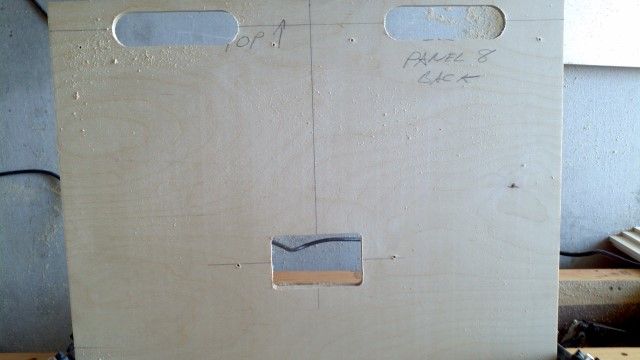

Template for jack plate.

Lovely cutout.

Handhold in top rounded over (1/4" roundover, BTW). Just on the top edge as the bottom edge of the hole will butt up against the quarter round. Pic shows rounded over vs. non-rounded over hole.

Stack of bottom panels, handholds rounded over on both sides. The center line of the holes are 2" from the edge...I went with that. Hope it works out.

Stack of tops.

Stack of backs. Even on the backs of the holes, which don't get rounded over, I broke all edges with 220-grit sandpaper. The jackplates may look a little high up, but I put them there by choice. I wanted as short an internal run of wire as possible. Less to tack down, less to vibrate too.

6/10 horizontal braces, handle hole and rounded over.

I realize that I have not cut holes for the casters yet. Bruce advised me to wait until at least the back is on so I will be better able to visualize how the backing plates for the casters will sit, how far to make the cut, etc. It's an easy cut with the circ saw, anyway. Check Bruce's "Old style T39 thread" at the bottom of the first page of "Build Threads" to see his caster backing blocks. I plan on doing something similar if not ripping him off outright. Again.

So, aside from putting the angles on the internal panels, all cutting is done. This afternoon's task: Mounting the drivers to the baffles to ensure the bolts line up with the tnuts, and checking for cone slap, which I really doubt I'll have, but better to check now than be able to do almost nothing about it later. Devil's In The Details, right? I know I have two or three holes on the driver side that don't line up well with the t-nut, so I'll have a bit of drilling to do, but no biggie, really.

Aside from actually assembling the cab, the only major things left to do for Prep Work are:

Mount drivers to baffles to check for proper bolt fit and cone slap.

Figure out the size of my access panel and one piece flange and get those glued up.

Thanks for looking.