Curved Grill WH10

Re: Black is Beautiful...

DuraTex. Nim is in Israel, where DuraTex is currently unavailable, so he uses what is available to him.DanielNY wrote:Is there any particular brand here in the states that makes textured polyurethane paint?N.Webber wrote: Textured polyurethane paint is applied to the outer shells, access covers and grills:

To Nim: I HATE YOU! I HATE YOU! I HATE YOU!

I know money often seals the deal, but seriously, quality is an investment, not an expense... Grant Bunter

Accept the fact that airtight and well-braced are more important than pretty on the inside. Bill Fitzmaurice

Accept the fact that airtight and well-braced are more important than pretty on the inside. Bill Fitzmaurice

Re: Black is Beautiful...

I didnt realize Duratex was polyurethane!DJPhatman wrote: Is there any particular brand here in the states that makes textured polyurethane paint?

DuraTex. Nim is in Israel, where DuraTex is currently unavailable, so he uses what is available to him.?

Built: T-60's, T48's, T-39's, DR250's, DR200's, Pro SLA's

Re: Curved Grill WH10

very nice build... i like the curved grill very much.

Re: Black is Beautiful...

Thanks guys…

As to the texture, the paint I used isn't textured by its nature. Its natural finish is plain semi-gloss.

It is fast drying so consecutive coats can be applied after only few minutes.

After applying the coats needed for thickness, the cab is left for a longer period (20 min) for the paint to cure

and then the texture is applied by reducing the air pressure to the spray gun, so that the paint is spattered rather then sprayed.

Unfortunately that's rightDJPhatman wrote:DuraTex. Nim is in Israel, where DuraTex is currently unavailable, so he uses what is available to him.DanielNY wrote:Is there any particular brand here in the states that makes textured polyurethane paint?N.Webber wrote: Textured polyurethane paint is applied to the outer shells, access covers and grills:

As to the texture, the paint I used isn't textured by its nature. Its natural finish is plain semi-gloss.

It is fast drying so consecutive coats can be applied after only few minutes.

After applying the coats needed for thickness, the cab is left for a longer period (20 min) for the paint to cure

and then the texture is applied by reducing the air pressure to the spray gun, so that the paint is spattered rather then sprayed.

Authorized Builder

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

Re: Curved Grill WH10

Didn't do much today...

Took the cabs off the painting beam,

Attached the feet:

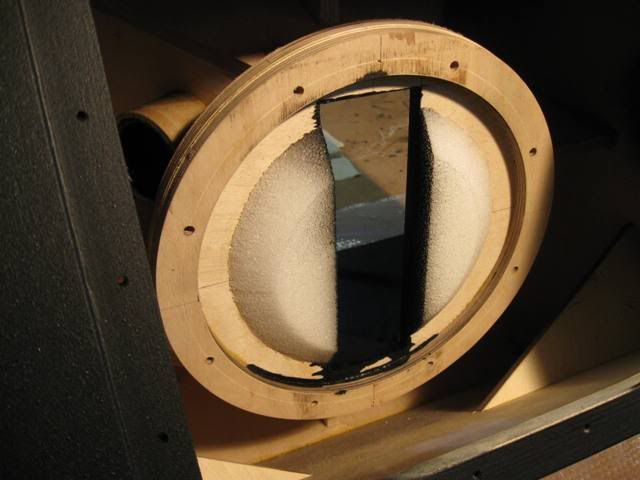

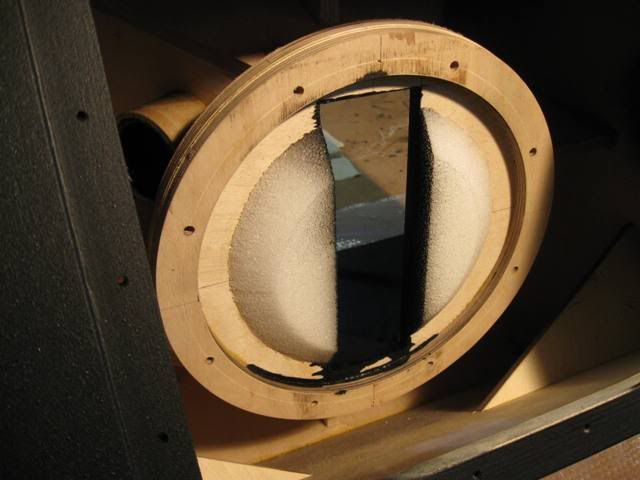

Painted the throat fillers where they might show:

And glued them in place:

That's it for now:

Took the cabs off the painting beam,

Attached the feet:

Painted the throat fillers where they might show:

And glued them in place:

That's it for now:

Authorized Builder

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

Re: Curved Grill WH10

A small auxiliary project…

Like the rest of my cabs, these WH10s are going to be stored in padded soft covers.

There is this small custom soft covers shop whose work I really like. They made most of my speaker covers over the years;

their covers are well made, constructed of heavy duty materials and hold up really nice.

They also turned out to be somewhat cheaper than another (big) local reputable case and cover manufacturer

that I did buy from once (for my DR290s) but wasn’t satisfied with their product as much.

So I decided to order the covers for my new WH10s from the ‘regular’ shop. Problem is, this shop is rather ‘old school’,

with some limitations when it comes to dealing with objects that aren’t basic and straight forward shapes.

Their normal approach in such cases is “OK, bring the cab over and leave it here so we can work by it”

Now, since the shop is located about an hour and a half drive from me (each direction), and considering it would mean

driving to them twice and also not being able to work on the cab in the mean time, I decided to do something else...

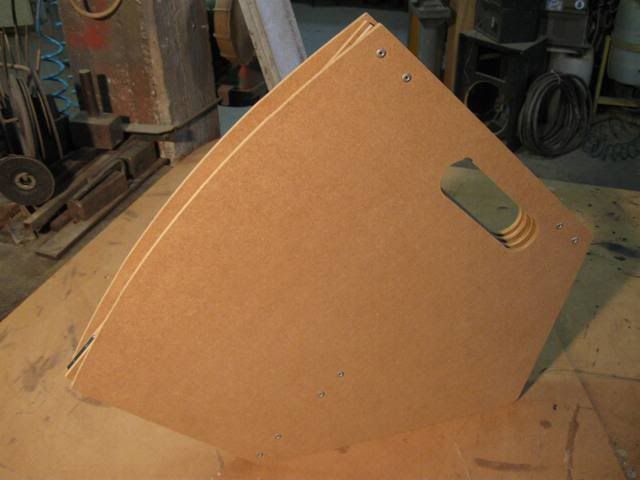

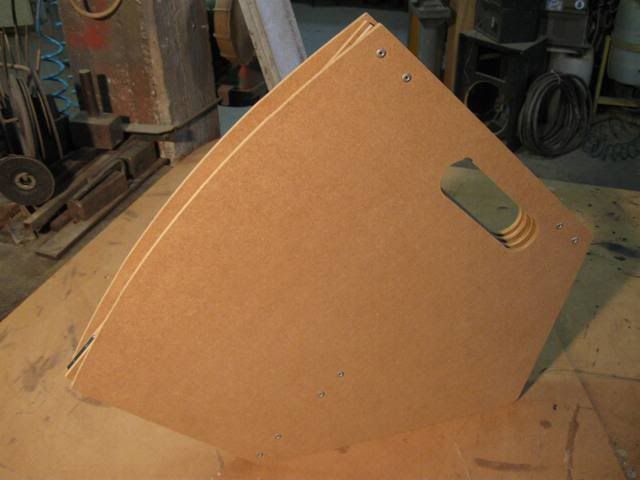

I made this foldable template/mockup of the WH10 out of 6mm MDF that I’m going to send over to them,

and with the above drawing of the cover configuration, I hope they will do it right

This is the cover drawing:

The folded mockup:

Half open:

Fully open and locked, 1:1 my WHs:

Like the rest of my cabs, these WH10s are going to be stored in padded soft covers.

There is this small custom soft covers shop whose work I really like. They made most of my speaker covers over the years;

their covers are well made, constructed of heavy duty materials and hold up really nice.

They also turned out to be somewhat cheaper than another (big) local reputable case and cover manufacturer

that I did buy from once (for my DR290s) but wasn’t satisfied with their product as much.

So I decided to order the covers for my new WH10s from the ‘regular’ shop. Problem is, this shop is rather ‘old school’,

with some limitations when it comes to dealing with objects that aren’t basic and straight forward shapes.

Their normal approach in such cases is “OK, bring the cab over and leave it here so we can work by it”

Now, since the shop is located about an hour and a half drive from me (each direction), and considering it would mean

driving to them twice and also not being able to work on the cab in the mean time, I decided to do something else...

I made this foldable template/mockup of the WH10 out of 6mm MDF that I’m going to send over to them,

and with the above drawing of the cover configuration, I hope they will do it right

This is the cover drawing:

The folded mockup:

Half open:

Fully open and locked, 1:1 my WHs:

Authorized Builder

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

Re: Curved Grill WH10

wow

2X OTop 112, 3012HO, melded - 2X T39, 27", Lab 12 - XF 212 - 4 DR250, 2 melded, 2 straight

2 20" T39 3012LF - WH10 - WH8 - in the shop - 2 more 20" T39s

http://saltandlighteureka.org still need a trailer

2 20" T39 3012LF - WH10 - WH8 - in the shop - 2 more 20" T39s

http://saltandlighteureka.org still need a trailer

-

Bruce Weldy

- Posts: 8647

- Joined: Fri Nov 27, 2009 11:37 am

- Location: New Braunfels, TX

Re: Curved Grill WH10

ripNdeb wrote:wow

Now that there's funny!

6 - T39 3012LF

4 - OT12 2512

1 - T24

1 - SLA Pro

2 - XF210

"A system with a few knobs set up by someone who knows what they are doing is always better than one with a lot of knobs set up by someone who doesn't."

Re: Curved Grill WH10

Yet anotherN.Webber wrote:I made this foldable template/mockup of the WH10 out of 6mm MDF that I’m going to send over to them, and with the above drawing of the cover configuration, I hope they will do it right

You may want to include a few pics of the finished cabs, so they understand that all 7 sides are closed, and the whole front is curved.

It still amazes me how you come up with simple yet very creative ideas, and then follow up by near perfect implementations of those ideas. I'm jealous of your craftsmanship. My hat off to you, sir.

- LelandCrooks

- Posts: 7242

- Joined: Thu May 04, 2006 9:36 am

- Location: Midwest/Kansas/Speaker Nirvana

- Contact:

Re: Curved Grill WH10

Quit it, just quit it. I'm not looking at anymore Nimrod Webber threads.

If it's too loud, you're even older than me! Like me.

http://www.speakerhardware.com

http://www.speakerhardware.com

-

Bruce Weldy

- Posts: 8647

- Joined: Fri Nov 27, 2009 11:37 am

- Location: New Braunfels, TX

Re: Curved Grill WH10

Look! A Martian!LelandCrooks wrote:Quit it, just quit it. I'm not looking at anymore Nimrod Webber threads.

Nah, it's just a little green Kansan.

6 - T39 3012LF

4 - OT12 2512

1 - T24

1 - SLA Pro

2 - XF210

"A system with a few knobs set up by someone who knows what they are doing is always better than one with a lot of knobs set up by someone who doesn't."

Re: Curved Grill WH10

X-Over time.

I am mounting the Xover board directly onto the back of the Speakon dish.

For this I prepared a small aluminum angle that attaches to the dish by the speakon bolts.

The board measures 90 * 125mm and is made of 4mm tough plastic I happen to have some scraps of.

The parts ready for assembly:

The hardware assembled:

All X-Over components in place:

And here after adding the common ground and soldering everything together:

I am mounting the Xover board directly onto the back of the Speakon dish.

For this I prepared a small aluminum angle that attaches to the dish by the speakon bolts.

The board measures 90 * 125mm and is made of 4mm tough plastic I happen to have some scraps of.

The parts ready for assembly:

The hardware assembled:

All X-Over components in place:

And here after adding the common ground and soldering everything together:

Authorized Builder

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

- 6 DR290

- Omni10.5

- AT, TAT

- Tuba 48

- 2 WH10

- Truck Tuba

http://www.boniton.co.il

http://www.bt-12.com Balanced Tilting Sounds Better...

-

wounded horse

- Posts: 315

- Joined: Sun Jul 12, 2009 9:18 am

- Location: Lincoln UK

Re: Curved Grill WH10

If only the whole working cabs with drivers and crossovers would collapse like that. I may try:-

2 X collapsible T39 24"

2 X collapsible Otop 12

2 X collapsible WH10

Inflatable desk/amps/processing.

2 X collapsible T39 24"

2 X collapsible Otop 12

2 X collapsible WH10

Inflatable desk/amps/processing.