The "Prep Work" always takes longest. Cutting the panels, making the complete baffle, cutting out handholds, jack plate openings, etc. Once all the little stuff is done, the big parts can start getting assembled! Got a good amount done today:

Baffles are complete (hurricane nuts mounted, "Harley Tricked" in place).

Handholds done on backs/tops and on the 6/10 horizontal brace ala "Bruce Style"

It might not seem like a lot for about 8 hours work, but those of you that have truly installed t-nuts "the right way" know it takes forever. Without a doubt, the baffles are the most time-consuming part of the build. I ran the bolt completely through each t-nut (hurricane, but t--nut is easier to type), making sure the threads were good. I threw away 6 t-nuts. Not taking any chances. I also drilled the driver side of the t-nut hole a bit larger than the hole for the t-nut itself to give me some wiggle room when bolting the driver down. My drill press is a tiny POS and it's throat isn't deep enough to drill all the driver mounting holes on a baffle of this size, so I had to do 4 on each baffle by hand. Trying to hold a drill perfectly vertical is not easy when you're really trying hard to do it.

Here's the setup I used for drilling the hole for the hold-down screw. The Harley Trick is much easier with t-nuts vs. hurricane nuts; you simply wedge a screw b/t the spokes vs. drilling a hole. But then again, w/t-nuts, you have to deal with the prongs sticking out into the driver cutout. Can't win, I guess. Anyway, piece of scrap with a 5/16" hole for the hurricane nut to sit in.

The setup on the drill press. Note the small spring clamp I used to hold the nut down while drilling. I originally was using my fingers, but metal gets hot when you drill it. Duh.

The screw is a #6 x 5/8", panhead (flat underside) screw. The hole I drilled in the t-nut is a 17/64. It was the next size up from 1/8" in the drill bit set I have and was the right size for this screw. YMMV.

One t-nut installed

8 T-nuts and screws installed in baffle. Keep in mind this is one baffle; all four are done.

One t-nut epoxied over. BTW, I bought the standard 2-part, instant mix, "5-minute" epoxy. Five minutes my ass! After 6+ hours, it's still tacky. Maybe b/c my garage is 100F? I hope it's dry by morning. I intentionally did not glop the epoxy all over the screw b/c I didn't want any getting into the threads. The screw is installed tightly, and the epoxy is almost 360-degrees around the edge of each screw.

One complete baffle.

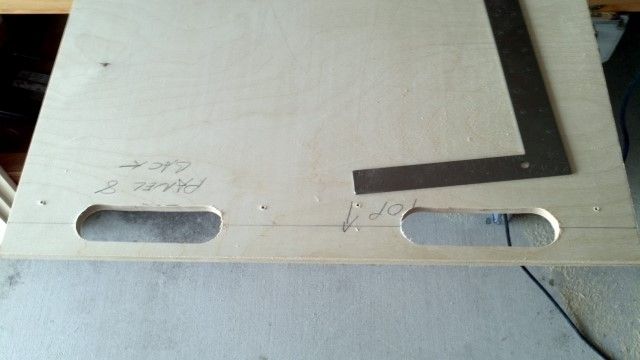

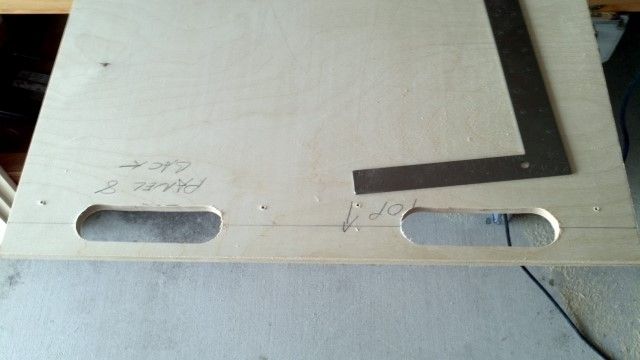

Next up were the upper handle holes in the top and back. I did the top first (no pics) and then the back. If you own a router, you need to make a template. "No, I can do it by hand."

WHY would you spend an entire day just cutting handholds when a template lets you cut out two handle holes in about 3-4 minutes? I am soooo glad I made a template!!!

Both upper handholds on the back cut out. They have not been rounded-over yet, but doing all the handholds will take me 30 minutes, maybe.

Back and Top mocked up so I could see if I got it right.

I was so happy that I got right, that I snapped a shot of me holding the quarter-round in place. Now here's something you don't see very day.

Last but not least, the handhold in the middle of the 6/10 horizontal brace. Bruce did this on his T39s and it's quite sturdy. Even if I never use it, my cab is about an ounce lighter than w/o it!

Putting the roundover on the edges will be a pain (I don't own a router table), but I want it there. BTW, how do you guys cut the groove in the 6/10 braces that this thing sits in? I can think of a few diff ways to do it, but want to know how YOU do it.

I wanted to get the terminal plate holes done today, but I ran out of steam. That'll be first-thing tomorrow. Once all this "prep work" is done, assembly will be quick. And then the tedium of finishing can begin.

A QUESTION FOR THE FORUM:

I also want to put hand holds on the front of the bottom panel, as shown in the plans/Sketchup (Oct11 Plans). If you look at the Sketchup, the top edge of the handhold butts right up against the front edge of the 6/10 brace. I am worried that due to variances in cut accuracy, build technique, etc, that my 6/10 braces will wind up overlapping the handholds and it'll look like crap. What would be safe measurements to place the holes? I.E. Bottom of the hole (nearest the edge) xxx inches from the edge, and hole centered xxx inches from the other edge. Thanks for any clarity you can lend on this. I would like the holes, but if I can't get a guarantee that they won't interfere w/the 6/10 braces, I'm leaving them out.

Thanks for looking. More over the next 3 days; I've cleared my calendar to do nothing but build.