Got mine a few years back in a kit....came with some clamps.miked wrote:Bosch jigsaw...

You'll love it.

Got mine a few years back in a kit....came with some clamps.miked wrote:Bosch jigsaw...

Oh, the anticipation!!!!!kenkenni wrote:Thanks Tom. That is what I plan on doing.I meant I can't wait until after everything is finished so that I can break them in

some more in my home theater.

Why?kenkenni wrote:Is it okay to coat the cavity that the woofer will be installed in with black underbed coating?

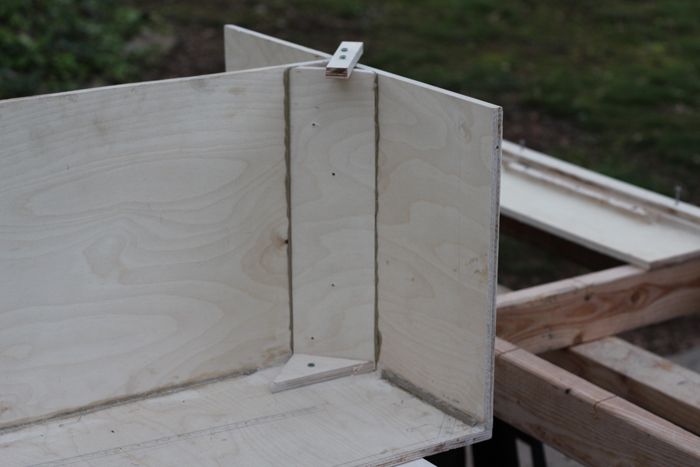

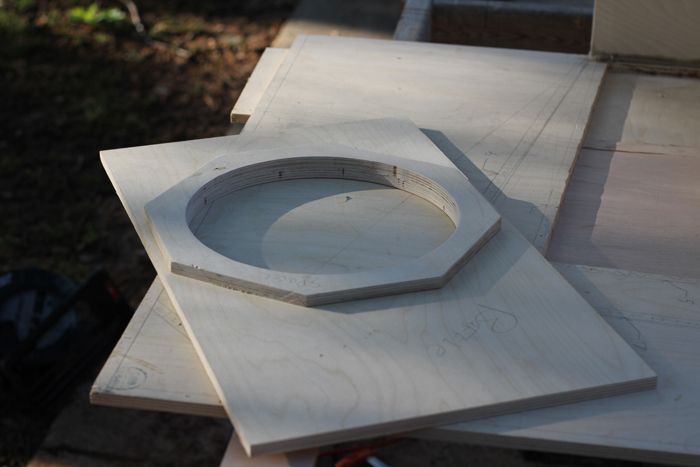

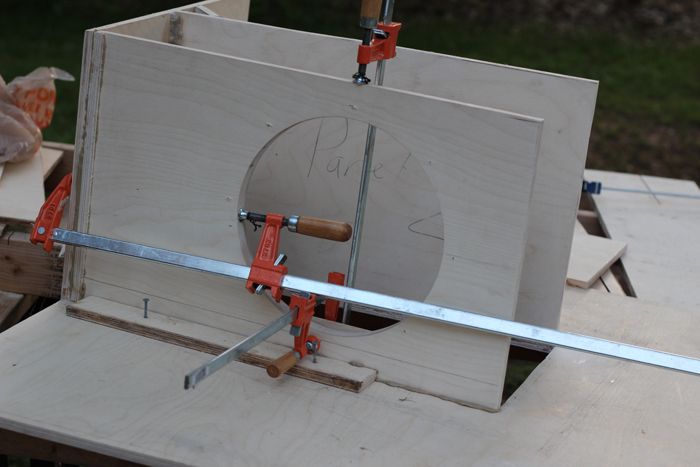

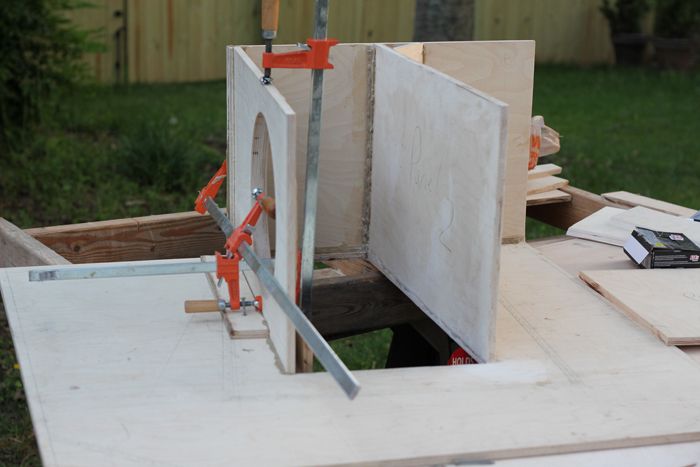

I'll betcha he's thinking "sound deadening/anti-resonance coating." That would be an unnecessary and time/material wasting step, kenkenni. The only rule for the woofer chamber is 100% absolutely air-tight. Doesn't matter what it looks like or if there's any coating/damping material on the walls. It's not needed and doesn't "give you" any return on investment. If you're at all worried about the chamber being air-tight, after the PL has dried for a couple of days, put a fillet of clear silicone over every panel joint and fillet it in with a gloved finger. Just the let silicone dry for 48 hours before installing the woofer/sealing the access cover.Bill Fitzmaurice wrote:Why?kenkenni wrote:Is it okay to coat the cavity that the woofer will be installed in with black underbed coating?

|

|