Page 3 of 4

Re: DCX Woes

Posted: Mon Mar 15, 2010 3:01 am

by AntonZ

Better not use a soldering gun. Rohs compliant soldering these days requires a high temperature tip, but not huge like the average soldering gun as that may heat up the board and surrounding components too much. It's better to run a regulated soldering station with a small tip.

Re: DCX Woes

Posted: Mon Mar 15, 2010 9:55 am

by bgavin

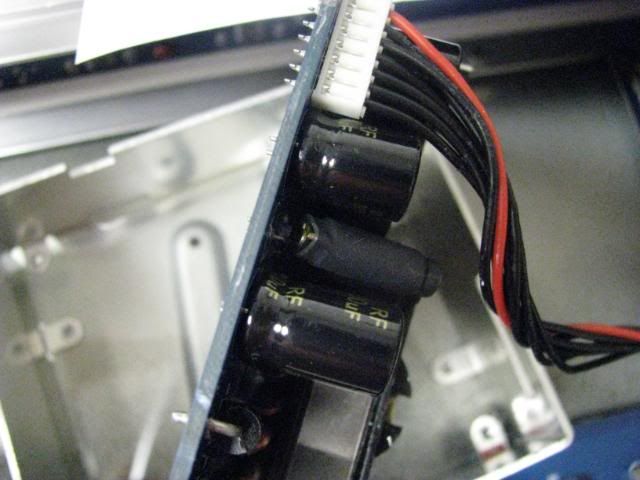

A leaning cap is not a problem.

A popped, bulged, or leaking cap must be replaced.

I use a Hakko 936 regulated soldering station. Mine was under $80 USD.

Very nice unit, very well made.

I use the 2.5mm chisel tip for computer board cap replacements.

Re: DCX Woes

Posted: Mon Mar 15, 2010 10:20 am

by Scott Brochu

bgavin wrote:A leaning cap is not a problem.

A popped, bulged, or leaking cap must be replaced.

I use a Hakko 936 regulated soldering station. Mine was under $80 USD.

Very nice unit, very well made.

I use the 2.5mm chisel tip for computer board cap replacements.

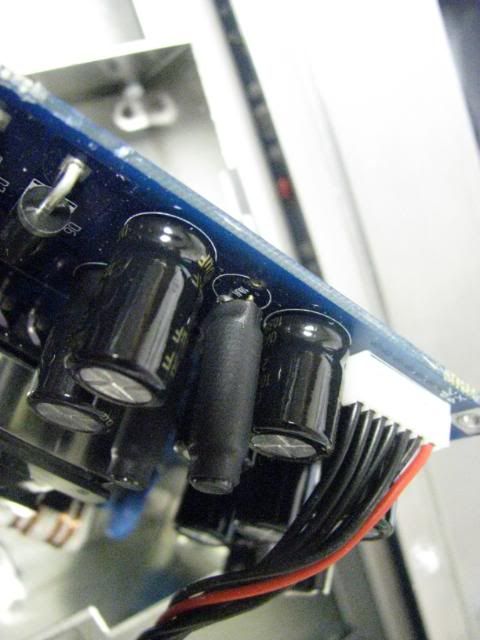

It's not bulged that I can see.

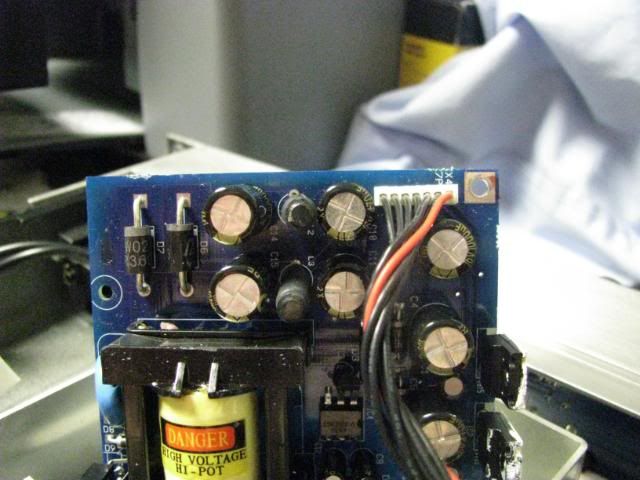

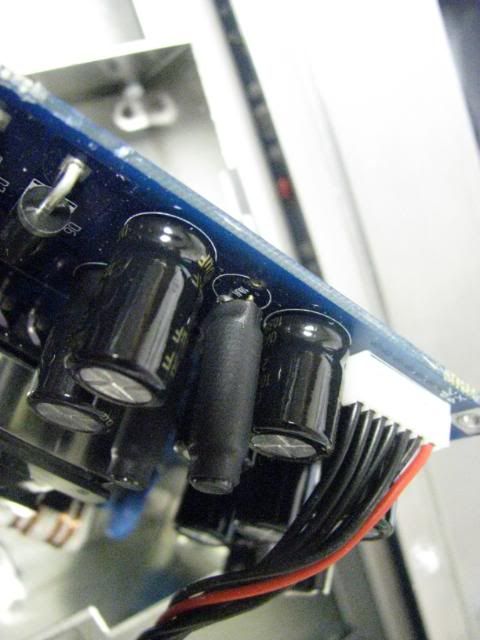

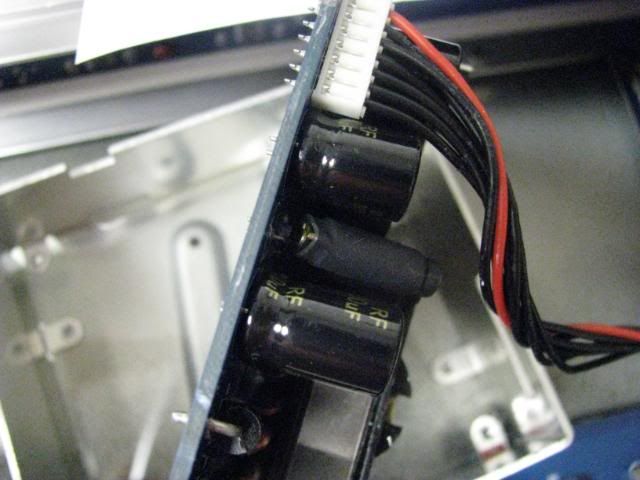

but do you see the missing wire? WTF never seen this......but I never usually open electrical devices either.

So heating the underside of this board with my 50 watt iron and try shoving a wire through the back and touching the other still there coming out the cap is not a good idea?

Re: DCX Woes

Posted: Mon Mar 15, 2010 11:33 am

by jcmbowman

Scott Brochu wrote:

So heating the underside of this board with my 50 watt iron and try shoving a wire through the back and touching the other still there coming out the cap is not a good idea?

It might be worth a shot, but I get nervous about soldering that far up on the lead wire for a capacitor. If it were me I'd find a suitable replacement cap and replace the one there with it.

Re: DCX Woes

Posted: Mon Mar 15, 2010 12:08 pm

by Radian

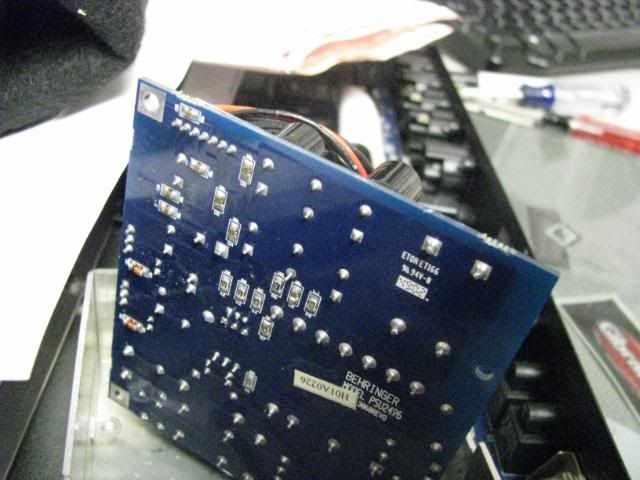

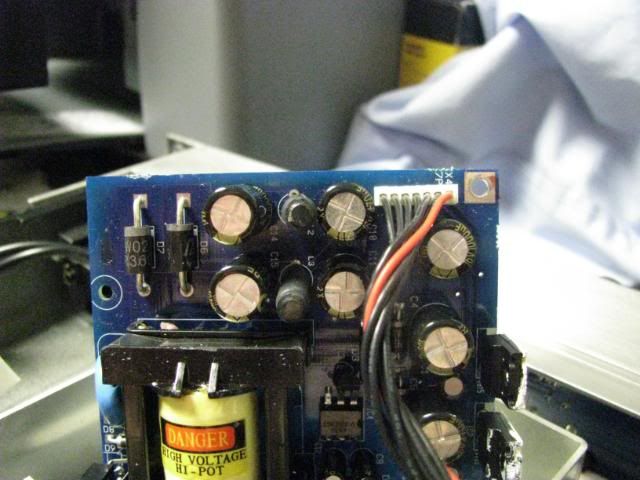

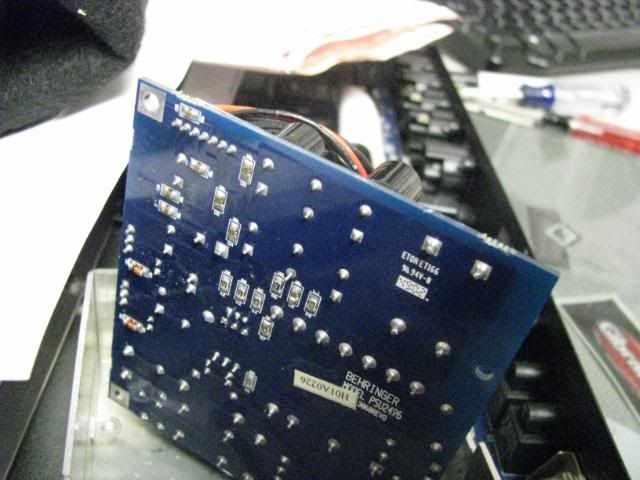

That's definitely not a cap. It looks to me more like an Rod-type inductor sealed in shrink tubing. How does the soldering pad look on the other side of the board? How about its sibling just behind it, are both its leads intact? Is there evidence of arcing (carbon or metallic traces)?

Re: DCX Woes

Posted: Mon Mar 15, 2010 12:16 pm

by Bill Fitzmaurice

Radian wrote:That's definitely not a cap. It looks to me more like an Rod-type inductor sealed in shrink tubing.

+1. I'd put a piece of resistor or capacitor lead through the hole, long enough to reach the nub, and solder it up. Then I'd put a couple of globs of silicone sealant between the coil and the caps on either side of it to stabilize it.

Re: DCX Woes

Posted: Mon Mar 15, 2010 4:50 pm

by Scott Brochu

Doesn't seem to be any indication there was any arcing or scoring.

I think I should just replace it. But how do I go about finding a replacment of the same thing?

Re: DCX Woes

Posted: Mon Mar 15, 2010 4:57 pm

by Zack Brock

If it is a rod inductor as it appears to be, it can take the heat of resoldering it that close. The rubber might get a little hot but I wouldn't worry about that. The rod inductor is just a coil of wire essentially. I would just resolder and not replace. If you are really worried about the heat, you could take a little metal alligator clip if you have one available and attach it to it to act as a heatsink while you solder.

Re: DCX Woes

Posted: Mon Mar 15, 2010 5:15 pm

by DJPhatman

De-solder the circled piece and insert a longer piece of wire that will reach the bottom of inductor. Solder to the board, solder the 2 ends together, and test.

And +1 to Bill's comment about silicone to brace it in.

Re: DCX Woes

Posted: Mon Mar 15, 2010 5:17 pm

by Scott Brochu

Zack Brock wrote:If it is a rod inductor as it appears to be, it can take the heat of resoldering it that close. The rubber might get a little hot but I wouldn't worry about that. The rod inductor is just a coil of wire essentially. I would just resolder and not replace. If you are really worried about the heat, you could take a little metal alligator clip if you have one available and attach it to it to act as a heatsink while you solder.

Your saying to go ahead and make a small hole from the other side and to heat, apply solder when the little bit of metal that is still sticking out of the inductor and meld them together with a gob of solder. Between the new metal (?) and the little piece?

Honestly I would try to do my best but most likely it wont come out like the picture. (my hands are big)

and attach the clip to what the rubber part of the inductor or try to wedge it in the 1/4" space I will have and attach it to the metal bottom of the good one?

THis is going to be fun

Re: DCX Woes

Posted: Mon Mar 15, 2010 5:22 pm

by Scott Brochu

DJPhatman wrote:De-solder the circled piece and insert a longer piece of wire that will reach the bottom of inductor. Solder to the board, solder the 2 ends together, and test.

And +1 to Bill's comment about silicone to brace it in.

What kind of wire? copper?

If this works I...I...I will pick up a bass guitar......BUT just hold it!

Re: DCX Woes

Posted: Mon Mar 15, 2010 8:46 pm

by Zack Brock

LOL!

You can use any old wire, solid core is preferred.

And if you have a vice you could hold it with that rather than have to use your hands.

If you really want to, you could ship it to me, I'll do it for you and ship it back (just that board)

Re: DCX Woes

Posted: Mon Mar 15, 2010 9:33 pm

by Scott Brochu

Zack Brock wrote:LOL!

You can use any old wire, solid core is preferred.

And if you have a vice you could hold it with that rather than have to use your hands.

If you really want to, you could ship it to me, I'll do it for you and ship it back (just that board)

Thank you!

I do have the vice and clips and I have an iron that has a point but might need to clean it, it has a little oxidizing on the tip.

I'll give it a go, but not tonight.

Re: DCX Woes

Posted: Tue Mar 16, 2010 12:08 am

by Gregory East

Putting all the good advice together I get this:

Unsolder the good connection from the board so you can solder your extension wire to the component with room to move (and wave the iron around without accidentally melting something else). Then replace the component in the board.

Spare hands are useful.

Re: DCX Woes

Posted: Tue Mar 16, 2010 8:11 am

by BrentEvans

Gregory East wrote:

Spare hands are useful.

I use

this. Works a treat.