Page 14 of 17

Re: OTop12 Build Thread

Posted: Fri Apr 05, 2013 11:26 pm

by Bruce Weldy

bmf wrote:When you get done with your painting put a piece of plastic wrap on the surface of the paint before sealing the can. It will keep it from skimming the top which is a pain to get out of the can.

While that's not a bad idea, I've had Duratex sit for a year then open it up. Just like the day I got it. Pretty amazing stuff.

Re: OTop12 Build Thread

Posted: Sat Apr 06, 2013 9:30 pm

by miked

I spent the entire day in the garage with just breaks for food and a quick trip to Lowes (you always run out of something...today it was glue sticks). I wound up taking off about 3/4s of the piezo elements, grinding down the offending mounting ears and reinstalling before wiring. I did make wiring a lot easier, so I highly recommend getting the elements aligned correctly from the get-go as opposed to doing it my way and wasting 3 hours. There are just THREE things left to do; build and install the crossovers, install the woofers, wire it up to the rear jacks. I'm shot, so I'll let the pics do the talking.

Diffusers installed.

Melded arrays wired. What a PITA this was. I sure hope the payback on the melded vs. straight arrays is worth the hours I spent. BTW: ALL arrays were tested prior to installation. As far as I can tell, all elements are working.

All arrays were installed with quick disconnects, which were properly crimped and then heat-shrinked. I did this w/serviceability in mind. Soldering would be better, but if I ever need to remove the array, this will help greatly. The wires feeding the array were also hot-glued in place; there will be no wires flopping around in the breeze, so the disconnects wont' be moving. They aren't going anywhere.

Something you don't see everyday; the rear of a melded array through the baffle.

And....done. Of course, they'll look much better with grills and corners. Coming soon.

Lonely back panels, waiting to be called to active duty.

Trying to fit the crossovers (both) on a 5x6 board is not turning out to be easy. I keep toying w/the idea of separating them into two boards, but I really want them both on one board. Less wiring mess that way. I'm done for the night. Thanks for looking!

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 10:04 am

by 88h88

miked wrote:I sure hope the payback on the melded vs. straight arrays is worth the hours I spent.

Totally worth it. You've done a really nice job on this build buuuuuddy.

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 12:12 pm

by miked

Thanks, 88h88. I think I've done OK, but the proof will be in the pudding when I fire them up this week. Got family obligations to take care of today, so I'll be lucky to get the crossovers laid out, boards drilled and at least the components hot glued/zip tied down. Probably won't get that far though. Needless to say, I am really looking forward to getting them done and HEARING THEM. I may not have any Titans to go with them (yet) but at least I have some subs to use. Not BFM, but they get the job done.

In other news, last night I came up with a brilliant (in my small brain, anyway) idea for stands. I've been tossing ideas around for almost as long as I've wanted to build OTops. I really wanted to get some metal stands fabbed up, ala PulseMan's awesome stands, but that is just not financially possible at this time.

My idea is relatively cheap, will look good and will be VERY, VERY sturdy (2 "very's" for emphasis); that is very important to me. How sturdy? "Sturdy" as in "Nothing short of a 60mph wind or 180-pound drunk dude crashing into them is going to knock them over."

Additionally, I already have much of the materials needed and the total cash outlay will be less than $150. There'll be a separate complete build thread (vs. an "in-progress" thread) in this forum when they are done, which should be by next weekend. No more hints as I'm not giving the idea away...you'll have to wait and see the final product.

Nothing groundbreaking; i.e. it's been done before, but not quite like this.

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 5:25 pm

by Grant Bunter

Pulseman's idea is awesome.

You can also achieve a slightly less industrial option with 2 regular stands side by side (ie for two sides you need 4 stands) and a platform with 2 regular tophats on it to attach it to the stands. Then strap your cabs to the platform.

I think Donny (Doncolla) does it this way and has pics somewhere.

It's worth a thought, and one day it will be how I do it too...

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 6:50 pm

by miked

Grant Bunter wrote:Pulseman's idea is awesome.

You can also achieve a slightly less industrial option with 2 regular stands side by side (ie for two sides you need 4 stands) and a platform with 2 regular tophats on it to attach it to the stands. Then strap your cabs to the platform.

I think Donny (Doncolla) does it this way and has pics somewhere.

It's worth a thought, and one day it will be how I do it too...

Well, there goes my big secret, down to the last detail. Thanks a lot, Grant. LOL! That's exactly what I'm doing. The majority of the expense is from the additional two stands I had to buy. A single tophat barely cuts it for one of these cabs (IMO), let alone 2. Whereas your average commercial top is tall and narrow, these are short and squat and have much more side-to-side "rocking weight" if you will. Platform mounting is definitely the way to go. Getting two stands ala PulseMan done up would cost almost as much as the four OTops...I just can't swing it. Plus, the setup/teardown has opportunities for things to go wrong. I.E. You'd always have to carry additional nuts/bolts/washers...just more stuff to lose. Not only is a platform supported by two stands very stable, it makes a nifty place to hang lights from, too.

More to follow. Still trying to get the crossovers laid out. I think I've got it, but am double checking things.

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 7:23 pm

by DJPhatman

miked wrote: Still trying to get the crossovers laid out. I think I've got it, but am double checking things.

Post a picture of your lay-out. A picture is worth a thousand words!

Re: OTop12 Build Thread

Posted: Sun Apr 07, 2013 11:29 pm

by Grant Bunter

miked wrote:

Well, there goes my big secret, down to the last detail. Thanks a lot, Grant. LOL!

miked wrote:Not only is a platform supported by two stands very stable, it makes a nifty place to hang lights from, too.

Now there's an idea I did not think of, good one!

Re: OTop12 Build Thread

Posted: Mon Apr 08, 2013 1:57 am

by Bas Gooiker

Can't you just make some support for your platform out of pieces of trussing? Very sturdy and easy to setup.

Re: OTop12 Build Thread

Posted: Mon Apr 08, 2013 7:00 am

by miked

I guess I could, but; I don't own any trussing, I can't weld (and don't own any welding equipment) and anything that has to be bolted together...has to be bolted together. Anything I tried to make out of metal would look "cobbled together" and probably wouldn't be safe.

Don't get me wrong; in my perfect world I'd have Pulseman's stands. But being that I don't do the DJ/live sound thing for a living, I can't see spending that kind of coin to have metal stands fabbed up, when I have an equivalent solution "at hand."

For me, it was quicker, easier and cheaper to just buy two more stands and two, 2'x4', 3/4" oak plywood to make the platforms from. I already had the tophats as I'd originally planned on installing them in the OTops proper. The build will require more wood than just those two sheets of ply, but I have plenty of scraps in the shop to use.

The stands I'm using (On Stage Stands SS7725B) are rated at 120 lbs capacity each. I take that with a grain of salt; figure 100 lbs each. Two stands give a capacity of 200 lbs. Two OTops (Delta Pro loaded) will be roughly 50 pounds each. Plus another 20 for the platform. That's 120 lbs, leaving me at least 80 pounds of wiggle room...figure a scanner-type light hanging under each platform...another 20 pounds. Still got 60 to play with. Sure; two stands per side takes up more room and leaves another 3 legs to trip over, but the stands' legs will be "interwoven" if you will...the additional footprint isn't all that much larger and the advantages in safety and stability will be well worth it.

I ran out of time last night; I wanted to take a pic of my proposed xover layout...I am 99% sure I got it right. It looks ugly, but it should work. The PITA detail is on the positive side of the high pass circuit. The capacitor, coil, 30 and 4 ohm resistors all have to be soldered together, basically. Not sure what the best way to do that is. I have a high-temp soldering iron, but am worried about damaging components with all that heat applied for a long time. Hope that makes sense. I may clip an alligator clip in there to use as a heatsink. Any tips would be appreciated.

I would really like to get the crossovers at least laid-out (mounting boards drilled, etc) tonight.

Re: OTop12 Build Thread

Posted: Mon Apr 08, 2013 8:41 am

by Tom Smit

miked wrote: Not sure what the best way to do that is. I have a high-temp soldering iron, but am worried about damaging components with all that heat applied for a long time. Hope that makes sense. I may clip an alligator clip in there to use as a heatsink. Any tips would be appreciated.

Start by having the components wired together. Then, with the soldering iron turned on and the tip in mid-air, occasionally touch the solder to the tip. When the solder melts on the tip (may take a few moments), then bring the tip against the connection and dab the solder wire onto the tip causing the solder to run down onto the connection. This part should take a max of three seconds.

Re: OTop12 Build Thread

Posted: Mon Apr 08, 2013 8:56 am

by miked

Ah, similar to what I did when wiring the arrays. Thanks, Tom. Sooo close at this point...can't wait to fire'em up!

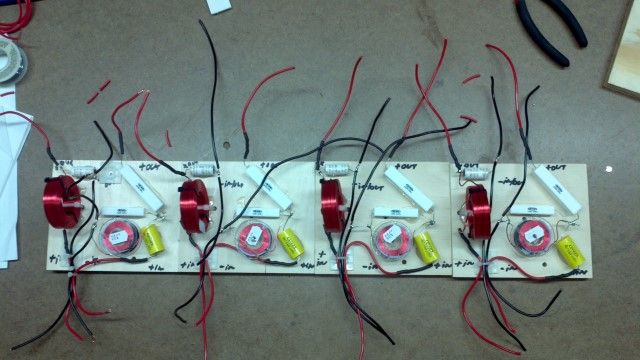

Crossovers done

Posted: Mon Apr 08, 2013 10:31 pm

by miked

Re: OTop12 Build Thread

Posted: Tue Apr 09, 2013 12:32 am

by gdougherty

Don't have pictures, but I found 6 position screw down terminal strips at Home Depot that made wiring of the crossover components much easier. There's an input pair, LF pair and HF pair with an input and output side to each. I did all the filter cabling on one side and the jack and driver cabling on the other. It's a very simple matter to unscrew anything I need in order to pull it. On the few occasions I've opened up the cab during repaints or upgrades it was most handy to pull the leads to the back panel.

Edit: Something like this:

http://www.allelectronics.com/make-a-st ... AMP/1.html

Re: OTop12 Build Thread

Posted: Tue Apr 09, 2013 2:24 am

by Grant Bunter

If you can, rotate the larger inductor about 20 degrees clockwise, so that it ends up perpendicular to the smaller inductor.

It wouldn't be an issue if the 2 inductors were more than 6 inches apart, but since that's not the case, best to do it now. It stops some sort of interference...