Your initial idea is nice. If I was to design a system from scratch, I would go the three point bracket method

(have a look at HK's Cohedra: http://www.cohedra.de/komponenten.php?m ... 01820c4c0#)

The bracket system certainly has clear advantages over the wire hangers (but as noted, done right costs a magnitude more…),

the obvious would be the inherent solution to the front edge pivot issue and of course the ability of ground stacking.

Fish has referred and clearly explained some of the key safety features that need to be imbedded into the proper design of an array'able cab.

A safe and quick attachment system is one. A simple bolt through the brace and into the cab's wall

(presumably a 'T' nut on the inside…) is far from 'safe'.

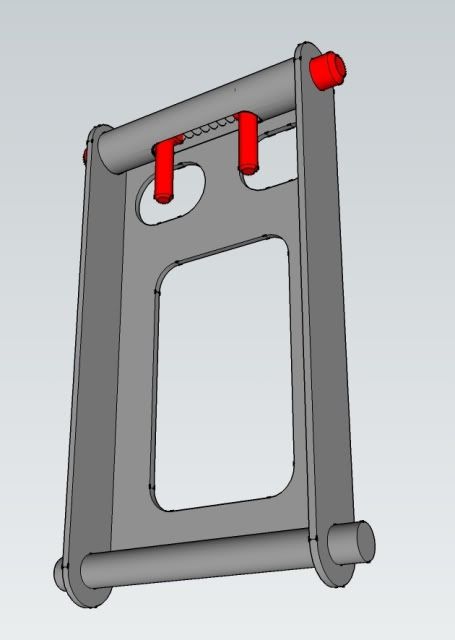

In most if not all commercial array flying systems there is some type of positive locking pin that goes through two static plates,

having the attached/removable brace sandwiched in between them, and held by the pin.

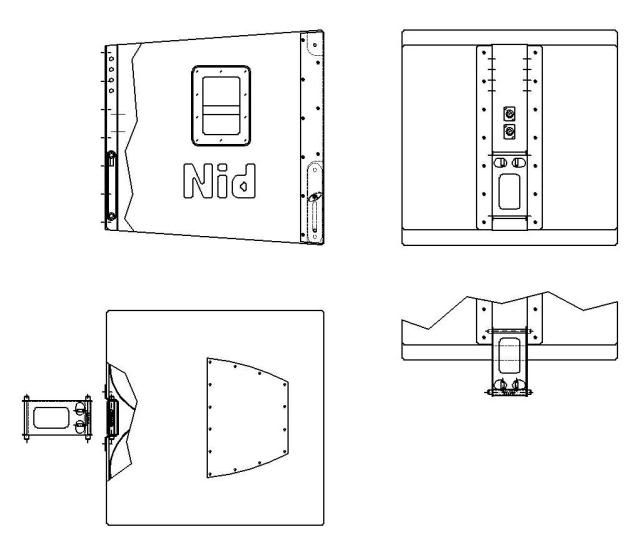

The bracket system also should be enclosed within the cab's outline and preferably holding all the movable parts in a neat and practical manner.

Of course, many other obvious aspects such as load ratings, duty and safety margins, material choice,

fool proof operation and more need to be addressed and fully calculated and thought out.

By the way, setting up 'my' system is indeed a one man operation (though can go somewhat quicker with additional help).

All attachments of the cables/flying bits is done while the cab is resting on the floor (or on top of another cab),

and only when everything is hooked up, the cab is lifted by the hand crank.