Page 2 of 4

Re: HowieZ's T24 build

Posted: Mon Sep 04, 2023 4:33 pm

by howiez

Seth wrote: ↑Mon Sep 04, 2023 2:43 pm

Nice to see it's already got the signature paint scheme

Re: HowieZ's T24 build

Posted: Thu Sep 07, 2023 9:13 pm

by howiez

Well, I have one success and one almost success. My Irwin super turbo 1" hole hogging bit thingy went wild making a hole for the body of the speakon, so it's a little oval now. No worry, the jack will cover it, but I still know it's there!

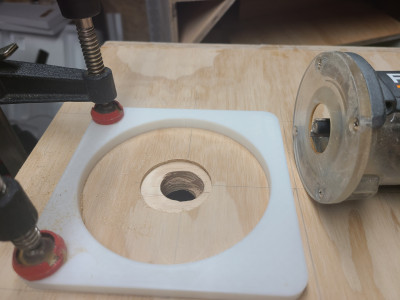

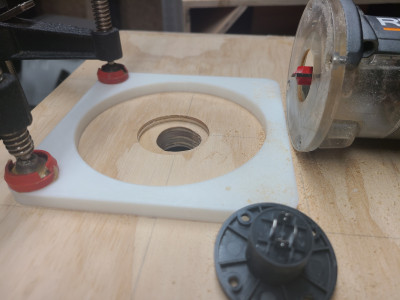

Normally I use a hole saw for the handles and cut between them with a jigsaw like the plans. When I cut my driver hole, I used an edge trimming router bit to match the size of one cab to the other. That gave me an idea to make a template for small holes and slots, since my circle cutting jig won't go below like 4-1/2" diameter. So I decided to try 3D printing a template for my Speakon and carry handle holes. We have a new Creality K1 Max at work, so I ran a few 'test' prints. At first the router jumped a bit because I plunged it, but next time i'll drill a pilot hole to be safe. Nothing was damaged or cut funny but the router wiggled a bit. Safety first right? So anyway I ordered a new template bit and made a slot template. Then I made a template the router would just ride inside for shallow work, in my case a 2" diameter counter bore to recess the Speakon. That one turned out a bit undersize. No worries, it's less than a $1 of plastic that is biodegradable, so i'll print a bit larger one tomorrow. The guided template was spot on, but the router base version was about 1/16" small. I have a feeling my router is not 3-1/2" in diameter but more like 90mm.

- Old bit and rough Irwin hole

- New bit and hole cleaned up a bit

- Template in place

- Super clean cut

Re: HowieZ's T24 build

Posted: Sat Sep 09, 2023 10:56 am

by howiez

I printed another inset ring for next time. Now I can spotface the 2" dia for the Speakon connector flange, then place the insert for the 1" clearance hole for the body. I used it to clean up mine a bit, but alas, i had destroyed them with the auger bit.

Re: HowieZ's T24 build

Posted: Sat Sep 09, 2023 2:24 pm

by Tom Smit

Even labelled "Insert for 3"! Well done. I like it! I have made jigs.....and then forgot to label them.

Re: HowieZ's T24 build

Posted: Thu Sep 14, 2023 9:42 am

by howiez

Re: HowieZ's T24 build

Posted: Thu Sep 14, 2023 1:46 pm

by Seth

You clever son of a bitch. That's awesome!

Re: HowieZ's T24 build

Posted: Thu Sep 14, 2023 11:19 pm

by Tom Smit

Beautiful job, Howie!

Re: HowieZ's T24 build

Posted: Fri Sep 15, 2023 6:26 pm

by howiez

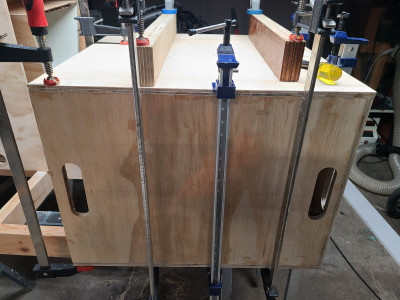

I glued the second side on cab 2 the other night, forgot to post pictures.

- side finally on

- scraped the PL after 2 hours

I got cab 2's access cover flange screwed and silicone caulked in tonight. I made it removeable, my driver barely fit through the opening unless upside down and I can't flip it inside. If it doesn't work, I'll glue it in and the driver will be permanent. No luck on cab 1. I started to test fit the driver and 4 of my 8 screws won't go in. I put T-nuts in and apparently they are just enough out of alignment... I can finger thread them with the driver out. That's what I get for building a bolt circle based on published specs. I had one do this on cab 2 but after a bit of driver wiggling I was able to get it started and hand 1/4" ratchet drive it home.

- access panel flanges installed

Re: HowieZ's T24 build

Posted: Fri Sep 15, 2023 7:31 pm

by Seth

You could always pound the T-nuts out, glue dowel in the holes, and use wood screws like the plans recommend. Alternately, you can try spacing the driver up off the baffle with some bits of ply while starting the fasteners. You might be better able to get an angle that works to get all of them in. Might also be able to adjust the T-nut alignment a little too if you stick a thin punch or screwdriver in and move them a little. I've had that happen a few times. Super frustrating, I know.

A few of the designs have just enough room to get the driver in when made with the recommended 1" access panel flange dimension. Your available window is 1½" smaller in each dimension than it otherwise would be. Glad you got 'em in there

I'm getting really anxious to hear your impression of these cabs, especially in contrast to your Frankenstein T48's.

Re: HowieZ's T24 build

Posted: Fri Sep 15, 2023 11:37 pm

by Tom Smit

Howie, if you know which screws are out of alignment, you could enlarge the driver flange hole a bit. Use a washer under the screw head if necessary.

Re: HowieZ's T24 build

Posted: Sat Sep 16, 2023 7:46 am

by Seth

^ I like that solution. Good thinking Tom

Re: HowieZ's T24 build

Posted: Sun Sep 17, 2023 8:13 am

by howiez

Tom Smit wrote: ↑Fri Sep 15, 2023 11:37 pm

Howie, if you know which screws are out of alignment, you could enlarge the driver flange hole a bit. Use a washer under the screw head if necessary.

This is a good idea. My first thought is to open up the ply over the T-nut for more wiggle room, I kept 'em pretty snug, like 1 drill size over the #10 screw, and just opened up the 'blocks' enough for the T-nuts to sink in. I'm going to buy a 10-24 tap and clean them all out first. I have two but they are so Harbor Freighty they won't even start in a clean hex nut in my hand.

Re: HowieZ's T24 build

Posted: Fri Sep 22, 2023 10:43 am

by howiez

Re: HowieZ's T24 build

Posted: Fri Sep 22, 2023 11:23 am

by Bill Fitzmaurice

howiez wrote: ↑Fri Sep 22, 2023 10:43 am

My only complaint would be getting in the mouth. Kind of hard with that gravity paint pot on top.

I do it in two steps. I place it upside down to hit the first coat, including the bottom. After it flashes I attach the feet. Then I flip it over to do the rest. I leave a couple of spots on the sides bare with the first coat to give places to grab to flip it over.

Re: HowieZ's T24 build

Posted: Sat Sep 23, 2023 10:14 am

by howiez

Bill Fitzmaurice wrote: ↑Fri Sep 22, 2023 11:23 am

howiez wrote: ↑Fri Sep 22, 2023 10:43 am

My only complaint would be getting in the mouth. Kind of hard with that gravity paint pot on top.

I do it in two steps. I place it upside down to hit the first coat, including the bottom. After it flashes I attach the feet. Then I flip it over to do the rest. I leave a couple of spots on the sides bare with the first coat to give places to grab to flip it over.

Thanks BIll. I think I kind of did this but upside down. I did put feet on late yesterday and flip it over and prime bottom. I just didn't think to leave spots for handling. I tried to use the cut in handles, but I had primed both and Duratex'd one partially. This morning I'll try to get in mouth better/the upside down parts of mouth...

Yearning for a turntable now... And a paint booth.