Page 2 of 2

Re: small rack case build

Posted: Sun Sep 27, 2015 4:33 pm

by heavybdrums

Bruce Weldy wrote:Question......from a ease of use standpoint, why did you put the driveracks on the bottom? It's hard enough to see those little screens without having to squat even further to get to 'em.

So that amp heat doesn't enter into the equation for the dbx. The stack is likely to have a rack box (without ears) that would have power cables and assorted items, and have wheels on it, on the bottom of the rack stack to raise it all up to a nice level and make it roll.

Also another 6u shallow rack for mains/subs/dbx and power conditioner (will move the one seen to this box). This way the whole rack stack will have wheels, be high enough, and more importantly no single box will weigh more than 50 lbs. We live in the mountains..everywhere is stairs and hills, wheels only work once on stage..not across the ground here. And mud ...did I mention the mud? This last Thur & Fri we went to a festival in North Carolina (very nice) and it rained the whole time, til we left on Sat. I couldn't imagine a heavy rack rolling across all that mud, but can imagine it being nice to move the stack once assembled and on stage to another spot on the stage.

Re: small rack case build

Posted: Sun Sep 27, 2015 5:40 pm

by Bruce Weldy

heavybdrums wrote:Bruce Weldy wrote:Question......from a ease of use standpoint, why did you put the driveracks on the bottom? It's hard enough to see those little screens without having to squat even further to get to 'em.

So that amp heat doesn't enter into the equation for the dbx.

Thought that might be your thinking....but, it's not an issue. I have three driveracks sitting right on top of 5 Crown amps. The heat isn't a problem....and I'm running mine outside in Texas heat all summer.

Re: small rack case build

Posted: Sun Sep 27, 2015 5:41 pm

by BrentEvans

Bruce Weldy wrote:heavybdrums wrote:Bruce Weldy wrote:Question......from a ease of use standpoint, why did you put the driveracks on the bottom? It's hard enough to see those little screens without having to squat even further to get to 'em.

So that amp heat doesn't enter into the equation for the dbx.

Thought that might be your thinking....but, it's not an issue. I have three driveracks sitting right on top of 5 Crown amps. The heat isn't a problem....and I'm running mine outside in Texas heat all summer.

+1... Driveracks are quite durable. Rack stuff for ease of use, not temperature control.

Re: small rack case build

Posted: Mon Sep 28, 2015 3:47 pm

by heavybdrums

Bruce Weldy wrote:heavybdrums wrote:Bruce Weldy wrote:Question......from a ease of use standpoint, why did you put the driveracks on the bottom? It's hard enough to see those little screens without having to squat even further to get to 'em.

So that amp heat doesn't enter into the equation for the dbx.

Thought that might be your thinking....but, it's not an issue. I have three driveracks sitting right on top of 5 Crown amps. The heat isn't a problem....and I'm running mine outside in Texas heat all summer.

oh ok I had noticed that the dbx when it was sitting on the amp got hot along with the amp, it caused no problems at the time, but good to know I don't have to be worried about that.

Re: small rack case build

Posted: Mon Oct 05, 2015 5:35 pm

by kenkenni

Are you able to share the plans and parts list. I built one a few years back, but it was just a square

box with rack ears used to hold an amp and a BBE processor. Yours looks much nicer and professional.

Re: small rack case build

Posted: Mon Oct 05, 2015 7:35 pm

by heavybdrums

kenkenni wrote:Are you able to share the plans and parts list. I built one a few years back, but it was just a square

box with rack ears used to hold an amp and a BBE processor. Yours looks much nicer and professional.

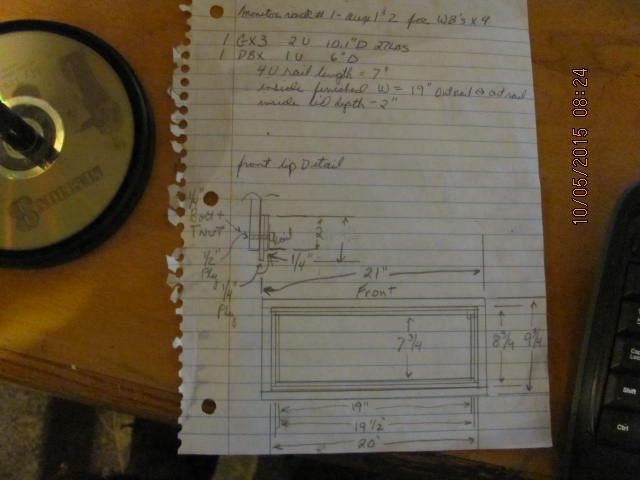

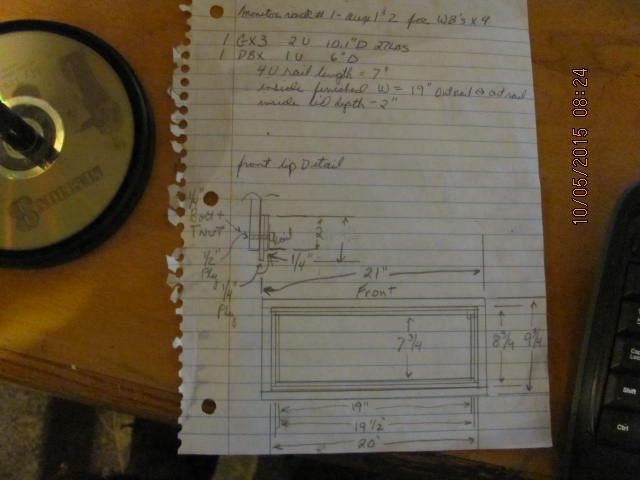

CUT LIST:

d=depth , w =width , h= height in inches, all parts 1/2" ply

2sides= 11&1/2(d) by 8&3/4(h)

2x top & bottom= 11&1/2(d) by 21 (w)

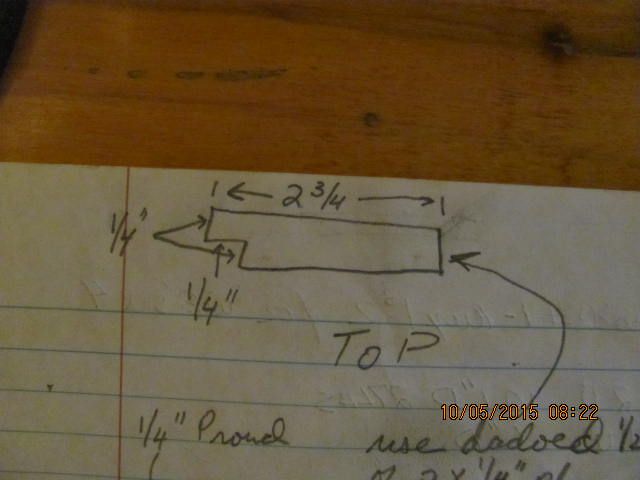

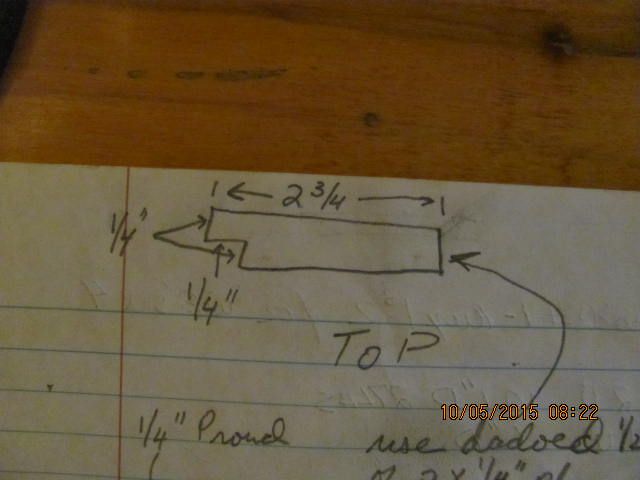

then for double 1/2" thick reinforcement and lip of front and back face, 2&3/4 (w) rip of ply cut to fit length, with 1/4" by 1/4" dado:

here is the front and back lip pieces to make 1" thick front and back lips for #10X1" rack screws, so you wind up with a 1/4" by 1/4" lip for the covers to fit on and some thin narrow weatherstripping for damp proofing:

Here is how the top/bottom and sides lap: Note the 4u rack rails are 7" long so the interior has to be a little more than that

Top and bottom are long, sides butt the top and bottom

These pencil drawings is all I made for them, hope it makes it somewhat clear. Just have to be sure the INTERIOR of the box winds up being about 19&1/4 wide and about 7&1/2-7&3/4 tall for a 4u box.

Where I got the rails:

http://www.sweetwater.com/store/detail/RKRL4

I just used whatever surface mount handles I could get and the penn elcom corners from speakerhardware.

When you make the lids make them 1/16 or so larger than the case so they fit over the lips of the front and back without being too tight.

That's about it just a correctly sized box with lids.

Re: small rack case build

Posted: Mon Oct 05, 2015 7:59 pm

by heavybdrums

Oh..just realized I didn't take a pic of the lids on:

The rear lid just like the front one only deeper to allow for cables to be left hooked up without stress on them. The clasps and handles from parts express made by penn elcom have to be surface mounted not flush or recessed.

If you notice I put the clasping mechanism on the case, if you want then on the lids(so they go away with the lids) you need to make the lids at least 2" outside depth for that to work. I was trying to make them small as possible so I made the front 1" inside and the back 2&1/2 inside and put clasps on the case where they would fit.

Re: small rack case build

Posted: Tue Oct 06, 2015 3:09 pm

by heavybdrums

kenkenni wrote:Are you able to share the plans and parts list. I built one a few years back, but it was just a square

box with rack ears used to hold an amp and a BBE processor. Yours looks much nicer and professional.

Just let me know if you have questions or if I wasn't clear .

Re: small rack case build

Posted: Tue Oct 06, 2015 7:07 pm

by kenkenni

Wow! Thanks for that. I copied all the info down and hope to start on this as soon as

I finish these last 2 2x6 SLAs. Thanks again!

Re: small rack case build

Posted: Tue Oct 06, 2015 7:52 pm

by heavybdrums

Anytime

Re: small rack case build

Posted: Sun Apr 30, 2017 1:28 am

by byacey

Good job! I've always hated those crappy SKB racks; they are flimsy, slippery, and have next to nothing for rack rail and intrinsic strength. Lately I've been building smaller racks with 12mm plywood; it works just fine.

Re: small rack case build

Posted: Mon May 01, 2017 5:19 am

by T_Gowan

Just a note. Something we were taught in High School shop class. When we made wooden boxes for whatever use you would build an completely closed box then cut off the lid. or front and back. always a perfect fit.

Re: small rack case build

Posted: Mon May 01, 2017 8:02 am

by Bruce Weldy

T_Gowan wrote:Just a note. Something we were taught in High School shop class. When we made wooden boxes for whatever use you would build an completely closed box then cut off the lid. or front and back. always a perfect fit.

+1 Exactly how I've built all of my boxes.

Re: small rack case build

Posted: Mon May 01, 2017 10:45 am

by y2kindyz

byacey wrote:Good job! I've always hated those crappy SKB racks; they are flimsy, slippery, and have next to nothing for rack rail and intrinsic strength. Lately I've been building smaller racks with 12mm plywood; it works just fine.

Hey byacey,

Thanks for resurrecting this thread, I have been wanting to build something like this. Gave great insight. Great build Heavybdrums.

Re: small rack case build

Posted: Mon May 01, 2017 10:56 am

by David Raehn

Here's what I do. I have several hundred units of rack rails and love putting them to work:

http://billfitzmaurice.info/forum/viewt ... =7&t=23941