Thanks Baja, if you happen to make it my way just let me know bud.67baja wrote:You're killing me now, Bob, with your fancy shmancy CNC contraption and all. I keep telling my wife our next vacation needs to be to your other night club, so one day I WILL BE THERE! or not... if the department of war and finance shoots me down. But still, I think I can speak for us all when I say: "I am in awe of your system(s) and build(s). Keep up the pics!"

At it again!! Night club number 2 sporting a BFM rig!

Re: At it again!! Night club number 2 sporting a BFM rig!

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: At it again!! Night club number 2 sporting a BFM rig!

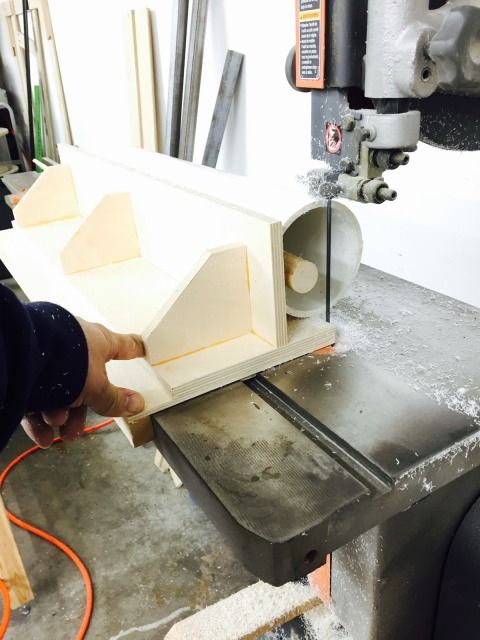

Today I did the part I hate the most... Cut PVC! Gets all over the place.. I did however modify my table saw jig to work on my band saw instead.. So much faster since you can cut the PVC in half in one pass, but more importantly dont have to worry about blade pinch on the table saw.

and plenty of extras..

and plenty of extras..

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

- LelandCrooks

- Posts: 7242

- Joined: Thu May 04, 2006 9:36 am

- Location: Midwest/Kansas/Speaker Nirvana

- Contact:

Re: At it again!! Night club number 2 sporting a BFM rig!

I'll have to give that a go. I just acquired a band saw. Did you use a re saw blade?

If it's too loud, you're even older than me! Like me.

http://www.speakerhardware.com

http://www.speakerhardware.com

Re: At it again!! Night club number 2 sporting a BFM rig!

It works great Leland. Give it a go you won't turn back.. Also no need for a re-saw blade, it cut perfectly straight with out it.LelandCrooks wrote:I'll have to give that a go. I just acquired a band saw. Did you use a re saw blade?

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: At it again!! Night club number 2 sporting a BFM rig!

One day I hope to be good enough at woodworking just to understand what you guys are talking about

Re: At it again!! Night club number 2 sporting a BFM rig!

haha Its never ending for sure.. I even have to use google now and then to clarify lol..escapemcp wrote:One day I hope to be good enough at woodworking just to understand what you guys are talking about

Today I made the backs and added some brownie points

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: At it again!! Night club number 2 sporting a BFM rig!

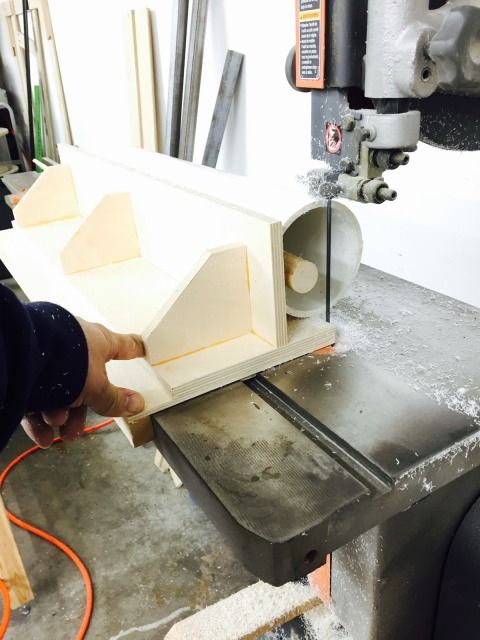

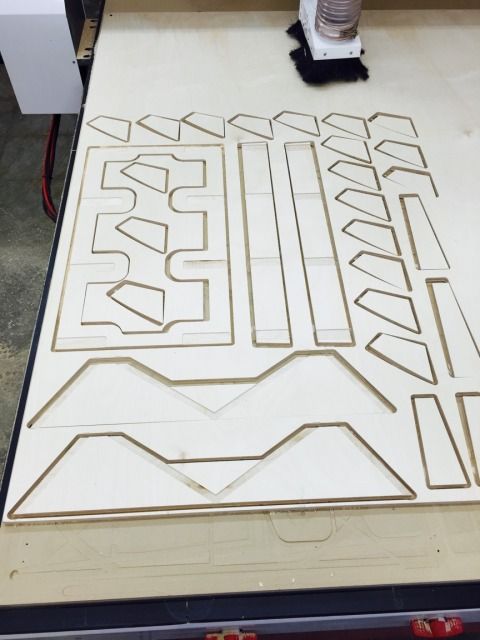

I got all the parts cut up for the compression driver module today..

I also cut up these helpful little jigs to hold the little parts while cutting the angles.

Unfortunately I have to look over my measurement since the horn parts seem to long.. Maybe the was intended and you just sand the rest off??

I also cut up these helpful little jigs to hold the little parts while cutting the angles.

Unfortunately I have to look over my measurement since the horn parts seem to long.. Maybe the was intended and you just sand the rest off??

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

- Bill Fitzmaurice

- Site Admin

- Posts: 29056

- Joined: Tue May 02, 2006 5:59 pm

Re: At it again!! Night club number 2 sporting a BFM rig!

+1. Read the plans!hifibob wrote:I got all the parts cut up for the compression driver module today..

Unfortunately I have to look over my measurement since the horn parts seem to long.. Maybe the was intended and you just sand the rest off??

The ends of the top and bottom reflectors will overhang ends of the sides, while the

middle reflectors will come to a point past the middle of the sides. Sand the point

of the middle reflectors down to flush with the leading edges of the sides; do the

same with the ends of the top and bottom reflectors.

Re: At it again!! Night club number 2 sporting a BFM rig!

Bob's not going to like that. For us it's a quick 5 mins with the sander. For him (and his squillion cabs) it's a major roadblock!

I guess, like many others, Bob should have read the plans more thoroughly and he would have foreseen this issue. You can lead a horse to water, eh??

Anyone seen my coat?

I guess, like many others, Bob should have read the plans more thoroughly and he would have foreseen this issue. You can lead a horse to water, eh??

Anyone seen my coat?

Re: At it again!! Night club number 2 sporting a BFM rig!

Ah, but with that machine he can make a test assembly, measure precisely how much smaller it should be, and build a precisely fitting part for the next (dozen) cabs. When you can cut wood with 0.001" accuracy and repeatability there's no need for "sand to fit" like there is for the rest of usescapemcp wrote:Bob's not going to like that. For us it's a quick 5 mins with the sander. For him (and his squillion cabs) it's a major roadblock!

Built:

1 Omni-15 Tall Boy

2 DR250s

2 Titan 39s

1 Omni-15 Tall Boy

2 DR250s

2 Titan 39s

-

David Raehn

- Posts: 676

- Joined: Tue Apr 30, 2013 5:56 pm

- Location: Colonial Beach VA

Re: At it again!! Night club number 2 sporting a BFM rig!

With Bob's track record, he won't sand....

He'll make a trick table saw jig and carry on as though nothing happened.

He'll make a trick table saw jig and carry on as though nothing happened.

BFM rig:

6 OT12

4 T48

4 WH8

Other:

56 box Electrotec LabQ rig

Way too many cables

6 OT12

4 T48

4 WH8

Other:

56 box Electrotec LabQ rig

Way too many cables

Re: At it again!! Night club number 2 sporting a BFM rig!

Bill Fitzmaurice wrote:+1. Read the plans!hifibob wrote:I got all the parts cut up for the compression driver module today..

Unfortunately I have to look over my measurement since the horn parts seem to long.. Maybe the was intended and you just sand the rest off??

The ends of the top and bottom reflectors will overhang ends of the sides, while the

middle reflectors will come to a point past the middle of the sides. Sand the point

of the middle reflectors down to flush with the leading edges of the sides; do the

same with the ends of the top and bottom reflectors.

Hahaha thanks guys.. although I can be guilty of not reading instructions but this time I did, unfortunately I did neglect to refer to sketchup to get proper assemblyBob's not going to like that. For us it's a quick 5 mins with the sander. For him (and his squillion cabs) it's a major roadblock!

I guess, like many others, Bob should have read the plans more thoroughly and he would have foreseen this issue. You can lead a horse to water, eh??

Anyone seen my coat?

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

Re: At it again!! Night club number 2 sporting a BFM rig!

hahaha Bob! after I JUST told you I made that exact same mistake on my ot212 build.

Built:

2x Tuba 30s delta12lf loaded (gone)

4x Otop12 d2512 loaded

8x t48s (18, 18, 24, 24, 30, 30) 3015lf loaded

2x AT (1 mcm, 1 gto 804)

2x SLA Pro (dayton pa6, 6 goldwood piezo loaded)

1x bastard XF208

2x OT212 (delta pro 450a loaded, eminence psd)

2x Tuba 30s delta12lf loaded (gone)

4x Otop12 d2512 loaded

8x t48s (18, 18, 24, 24, 30, 30) 3015lf loaded

2x AT (1 mcm, 1 gto 804)

2x SLA Pro (dayton pa6, 6 goldwood piezo loaded)

1x bastard XF208

2x OT212 (delta pro 450a loaded, eminence psd)

Re: At it again!! Night club number 2 sporting a BFM rig!

billkatz wrote:Ah, but with that machine he can make a test assembly, measure precisely how much smaller it should be, and build a precisely fitting part for the next (dozen) cabs. When you can cut wood with 0.001" accuracy and repeatability there's no need for "sand to fit" like there is for the rest of usescapemcp wrote:Bob's not going to like that. For us it's a quick 5 mins with the sander. For him (and his squillion cabs) it's a major roadblock!

You guys know me to well lol.. Ive since re-cut these parts with some modification to expedite these.. I basically dado all the mating surfaces and increased the size of the cleats to help hold the little pieces straight and square while tacking together with brad nailer. Now I can get the brad nails plenty far enough out the way when it comes time to mill out the pocket holes for the module mounts.With Bob's track record, he won't sand....

He'll make a trick table saw jig and carry on as though nothing happened.

I will however keep this one for my go to reference module while assembling them..

My build thread.. 11 T60's and 10 DR280's http://billfitzmaurice.info/forum/viewt ... 30&t=19854

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567

My Review! http://billfitzmaurice.info/forum/viewt ... 13&t=20567