Page 2 of 6

Re: Slim Tuba HT Trials

Posted: Tue Apr 30, 2013 6:03 pm

by kenkenni

I guess this makes me an official DIYer!

[img

][/img]

My Circle/Edge Guide and various router bits.

[img

][/img]

My Kreg Jig for my routers.

[img

][/img]

A closer look at my circle jigs.

[img

][/img]

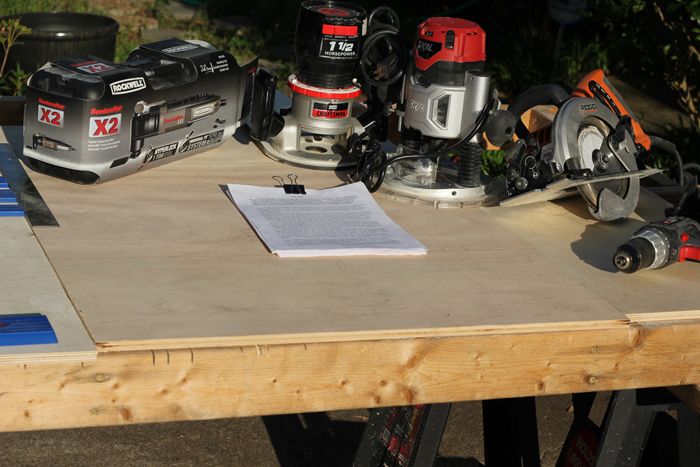

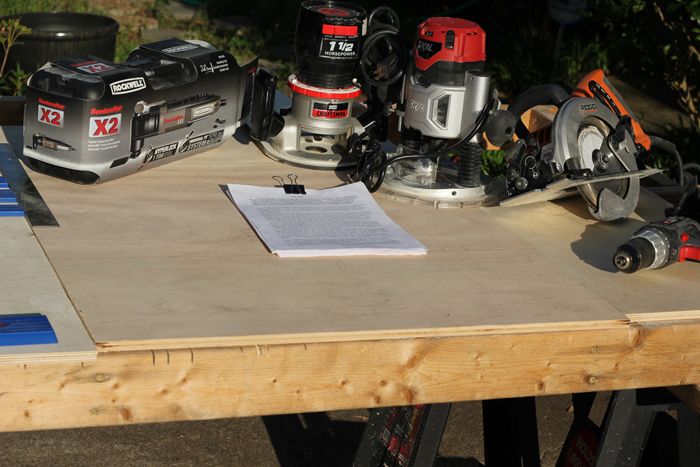

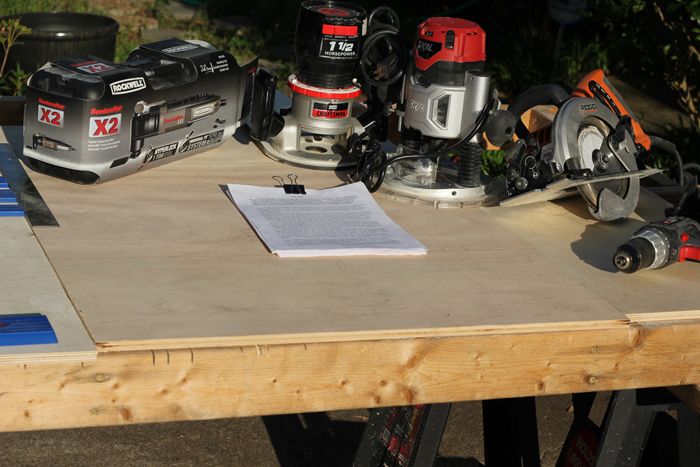

The Master Plan.

[img

][/img]

Was a bit nervous and in a rush as you can tell. This panel was trashed though as I wasn't too proud of the outcome. I have re-cut

another one and it is a hundred times better looking as I was a little more concentrated.

[img

][/img]

Hope to bring you more soon.

Re: Slim Tuba HT Trials

Posted: Tue Apr 30, 2013 6:26 pm

by kenkenni

Just a couple more pics.

This cut-out has been trashed. I was not happy about the final result so I cut a brand new

one. I'll post a pic of the better version soon.

Here is the opening after plunge-cut. I smoothed out the edges with the X2 there-after. Just still a tad bumpy, but you can hardly

tell when the new access panel is in place.

I decided to cut these parts early. The brace was shaped with the X2. It was also used to plunge the triangles off the spacer.

I hope to bring you more soon.

Re: Slim Tuba HT Trials

Posted: Tue Apr 30, 2013 10:04 pm

by Radian

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 6:51 am

by miked

Very nice; you're off to a good start. I've been thinking about getting one of those vibrating multi-tool things. How difficult is it to cut a straight line with one? Due to the shape/design of the tool, you can't use a guideboard with it. I'm pretty bad at freehanding any type of cut. I do OK cutting a straight line on the bandsaw, but freehanding a jigsaw...my cuts look like an EKG strip.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 12:02 pm

by kenkenni

Miked, it is really easy to cut a straight line with this tool. I actually used a guide board to make sure the edges stay straight.

It comes with several tool attachments to help you in different ways even a sanding attachment. The oscillator doesn't even

come in contact with the object your working on, only the attachment. It's pretty light and has variable speed. Real easy to

control. You should get one. I have used it more than my circular saw, especially for plunge cutting.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 12:09 pm

by miked

Thanks for the reply. Plunge cutting is essentially the sole reason I'm looking into one. Also, due to the thinness of the blade, the kerf of the cut (material the blade cuts out) is very minimal, so your access cover doesn't have this big old 1/8" or more gap all around it.

Using the "plunge with the circular saw and finish with the jigsaw" method is a recipie for an ugly, jagged cut. Speaking strictly for myself, of course. My jigsaw is a POS...need a new one of those too. Ah, it never ends.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 12:14 pm

by Bruce Weldy

miked wrote:

Using the "plunge with the circular saw and finish with the jigsaw" method is a recipie for an ugly, jagged cut.

For access covers and baffle cutouts - I do a rising cut on the table saw. It works great and you can take it right up to the line and not have to use a jigsaw to finish.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 12:48 pm

by miked

Bruce Weldy wrote:miked wrote:

Using the "plunge with the circular saw and finish with the jigsaw" method is a recipie for an ugly, jagged cut.

For access covers and baffle cutouts - I do a rising cut on the table saw. It works great and you can take it right up to the line and not have to use a jigsaw to finish.

What about the "short sides" of the cutout? The only rising cuts I've done is the slots on my crosscut sleds. Exact same method, I know, but those were long, straight cuts.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 1:30 pm

by Bruce Weldy

miked wrote:Bruce Weldy wrote:miked wrote:

Using the "plunge with the circular saw and finish with the jigsaw" method is a recipie for an ugly, jagged cut.

For access covers and baffle cutouts - I do a rising cut on the table saw. It works great and you can take it right up to the line and not have to use a jigsaw to finish.

What about the "short sides" of the cutout? The only rising cuts I've done is the slots on my crosscut sleds. Exact same method, I know, but those were long, straight cuts.

I do the short ones the same way and I don't use a sled. Just get the fence set properly and slowly bring it up while putting pressure down on the stock. You get back cuts on the backside, but you can't see the backside anyway and you can fill em' with PL if you want when you are putting them in the cabinet.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 1:48 pm

by miked

Thanks, Bruce. I appreciate the tips from the Titan of the Table Saw.

Re: Slim Tuba HT Trials

Posted: Wed May 01, 2013 9:40 pm

by kenkenni

Today I decided to attach the baffle to the spacer and assemble panel 1. It got dark so I'll get pics up soon.

I gotta say there are times where I really wish I had a table saw I was trying to go ahead and trim all the 45*

angles for the panels that require them except all my practice cuts were not too great. The small panels don't

have enough meat for my circular saw to ride on and my clamps get in the way of the housing of the saw. I

cut one of the panels, but cut along the wrong side. I cut the 45* on the short end instead of the long end.

No biggie though. I had plenty of extra scrap so I cut another panel.

Re: Slim Tuba HT Trials

Posted: Thu May 02, 2013 10:03 am

by Radian

kenkenni wrote:... my clamps get in the way of the housing of the saw.

I can appreciate that frustration. You could try raising the saw as far as you can go yet still make it through the workpiece. The blade need only to break through by a mm or two and that will maximize the clearance space underneath your saw.

Re: Slim Tuba HT Trials

Posted: Thu May 02, 2013 10:12 am

by Bill Fitzmaurice

miked wrote:

Using the "plunge with the circular saw and finish with the jigsaw" method is a recipie for an ugly, jagged cut.

Only if you run the circular saw freehand. Using it with a sled if you don't get a perfectly straight and true cut you should quit your present line of work and get a job at Oscar Mayer.

Re: Slim Tuba HT Trials

Posted: Thu May 02, 2013 12:19 pm

by subharmonic

Personally I don't like the super tight access cover. I have done a couple and find opening them for service/maintenance a major PITA as the gasket/weatherseal kinda glues them down over time. By the time I pried them open the wood around the access was looking shabby. But I build in pine also sooo? Just my $.02 YYMV

Re: Slim Tuba HT Trials

Posted: Thu May 02, 2013 3:23 pm

by miked

Part of my frustration with the "circular saw plunge/finish with jigsaw" stems from the fact that my jigsaw is a POS...I've needed a new one for a long time. Also, while I do have a circular saw sled (an 8-footer...I don't mess around!) I don't have a jigsaw sled. These are personal problems, I know.

I've been drooling over the big Bosch jigsaw...can't remember the model number but it's $170 at Lowes

][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img] ][/img]

][/img]