I made some good progress tonight. Wish I could keep going but I get up very early for work. This weekend will be a different story, however, and I'm looking forward to that.

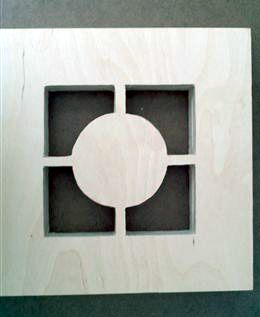

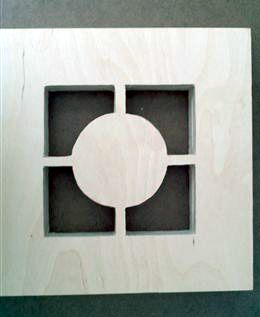

First things first. I got my phase plug extensions glued up and the worst stack is out of round by maybe 1/16th on one side. They'll clean up easily on the sander. Thanks again for the tip, Bruce.

I finally got the darn horn panels cut. These were almost as difficult as the baffles for me! I'm sure there's a more efficient way to cut them, but I had to:

1. Cut the pieces to 14 x 12

2. Cut the short end to 11 3/4 with a 34-degree angle

3. But that still left the "long edge" of the angle at 12"

4. Flip the panel so that the angle cut is now against the fence

5. Cut the overall length of the panel down to 11 3/4"

The panels are perfect, if I do say so myself. Too bad I used up 1.5 SHEETS of 5'x5' BB to get them. It took me THREE tries...cutting out 24 panels before I got here. Hey, it's my first time. Seriously, this part sucked. Hopefully another noob will read this and avoid wasting wood and time. Anyway, end result is what matters.

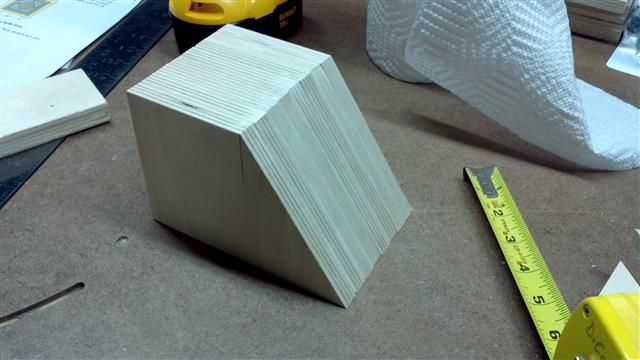

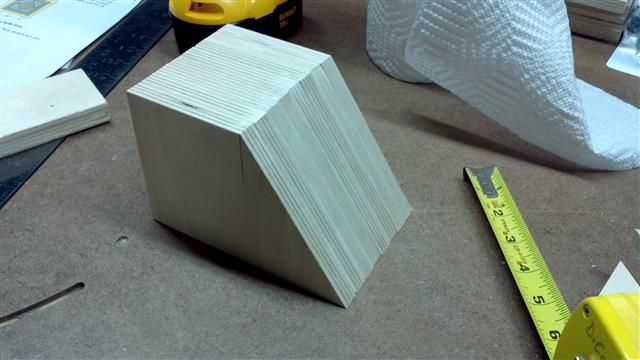

Got the horn braces cut. I ripped a 14 x 5 piece of BB down to 4" wide, then cut the 4 x 5 5/16" blanks. I used my TS sled to cut these small parts. Note the clamped stop block.

Then, I measured off 3 3/16" off one side, marked it and rough cut it on the bandsaw.

Then, using Mister Sander here...

I sanded down to the line and wound up with a matching stack. They are all within 1/32" of each other on the angle cut.

That's all for tonight. I realize I'm playing catchup; I was expecting to be halfway through glueup by now, but hey, at least I'm redoing the pieces I feel are substandard. If you can't find the time to do it correctly the first time, how will you find time to do it again to fix your mistakes? Being an IT guy by trade, I tell this to my bosses all the time. They want it up "right now" and most times, that's just not possible.

Tomorrow I'll true up the phase plugs on the sander. I was going to patch the screw holes with wood putty, but Bruce reminded me that once they're glued to the baffle there AREN'T any holes. (Why didn't I think of that?). Thank you, Bruce. I will also cut the spacer rings for the drivers and mount it to the baffles before mounting the baffle to the bottom panel (if I get that far). FWIW, I don't understand why it's not in the plans that way (mount ring to baffle before mouting baffle to bottom). Trying to attach the spacer ring to the baffle once the baffle is mounted, then hold the woofer in place to drill the mounting holes would be a royal PITA and wouldn't come out right half the time. IMO.

More tomorrow...if life doesn't get in the way, that is.