Page 2 of 12

Re: Table Tuba build!!

Posted: Sun Nov 07, 2010 9:00 am

by psg

Ahh! Panel 5! If it's like the THT, that was also my panel from hell. The angle makes it so hard to line up with panel 1. Patience is required here.

Re: Table Tuba build!!

Posted: Sun Nov 07, 2010 8:01 pm

by digital_chris

Lol, yeah, it was a pain.

Here is my progress from last night, the hour and a half panel... LOTS of brads through the sides. Well, about 3 or 4 but still annoying...

Brad...

Brad...

Brad(ssss)...

Here is where some PL started separating, not sure if it's separating from the seam or just a layer of PL separating from the bottom layer, hmmm...

Next stop, 3/5 brace.... TBC

Re: Table Tuba build!!

Posted: Tue Nov 09, 2010 11:07 pm

by digital_chris

Re: Table Tuba build!!

Posted: Fri Nov 12, 2010 8:46 pm

by digital_chris

Re: Table Tuba build!!

Posted: Fri Nov 12, 2010 11:17 pm

by Radian

I wouldn't sweat the brads only being on one side at all, the PL holds better than any nail could ever hope to. Braces look good - thumbs up.

digital_chris wrote:Definitely, if I do this again which I know I will, I will go with at least plywood (probably baltic birch) for any units after this.

We weren't kidding about the weight, were we?

At least the MDF doesn't warp after you cut it.

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 12:35 am

by digital_chris

Lol, it is pretty hefty for sure

I heard that MDF isn't too much heavier than say baltic birch though. I just went with MDF because it's hard to source BB around me and if I screwed up, it wouldn't be too much money or time to get another piece.

Looks like I'm all set to continue. The PL really holds that good? The MDF would probably crumble before the PL lets go is what you're saying?

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 10:42 am

by subharmonic

digital_chris wrote:The PL really holds that good? The MDF would probably crumble before the PL lets go is what you're saying?

Try glueing some scrap wood together. Let it cure, they try to get it apart. My THT fell off a sawhorse during repositioning. It ripped a hole in the plywood and broke the sawhorse. The glue was still in tact.

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 11:28 am

by bzb

MDF is a good bit heavier than BB. I finally got a hold of a sheet of Arauco at Lowes. Forgot to see if they had a scale, but it definitely feels lighter than an equivalent BB panel once cut. I've had multiple sheets at Suwanee Lumber weighed, although it's certainly not scientific. However, the scale did always get my weight pretty dang close, so I trust these measurements:

A 49x97" 3/4" thick MDF sheet from Suwanee Lumber is between 92 and 95 lbs.

A 60x60" 1/2" thick 13-ply BB sheet from Suwanee Lumber is between 50 and 53 lbs.

And wow, you really are messy with that PL

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 1:04 pm

by subharmonic

bzb wrote:

And wow, you really are messy with that PL

I like it. No leaks.

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 4:55 pm

by SeisTres

bzb wrote:

A 49x97" 3/4" thick MDF sheet from Suwanee Lumber is between 92 and 95 lbs.

A 60x60" 1/2" thick 13-ply BB sheet from Suwanee Lumber is between 50 and 53 lbs.

Don't know why people keep bringing up the weight of the cab from mdf as from those number you provided, the mdf is right around 10% heavier. It is heavy but really not much heavier than BB. I think people just automatically think of cabs that are made out of 3/4" mdf, not THOSE things SUCK!, but 1/2" is pretty ok. However, I think there is a bigger difference going from arauco to BB. It just sucks that I can't find it anymore since I want to finally start my DR200's but I only half a sheet of mdf

Re: Table Tuba build!!

Posted: Sat Nov 13, 2010 10:38 pm

by digital_chris

bzb wrote:And wow, you really are messy with that PL

Haha, yeah, I BETTER not have any leaks after that mess I made

And to update at the same time, the final "side" is on (my top actually) and I will wait for that to dry and then install the final two braces

Almost time to run tones through it, I'm excited but nervous at the same time

Re: Table Tuba build!!

Posted: Tue Nov 16, 2010 12:27 am

by digital_chris

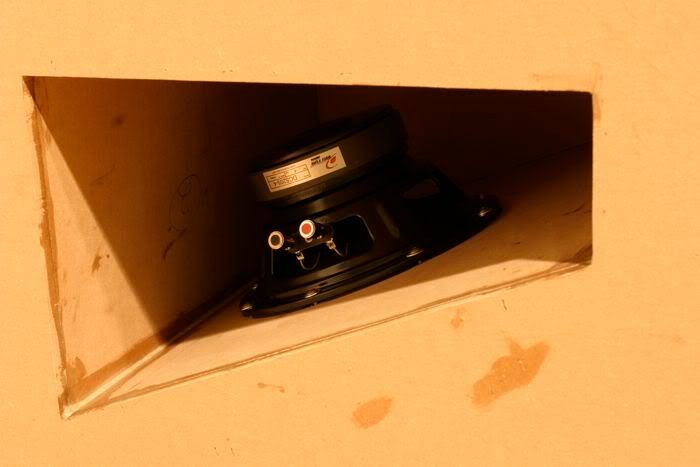

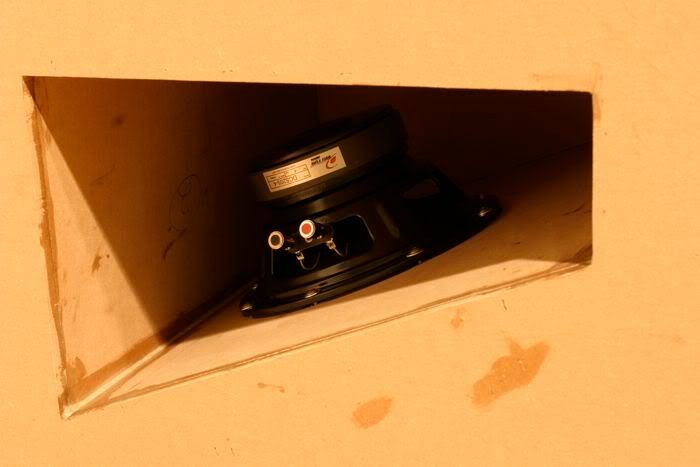

Well, finally finished!!! Check out the pics...

There's not much to look at, lol but there she is

I ended up using my cheapo Pyramid PA amp so I can get some tones through it. Ran a 30hz tone for a few minutes up to 7-8 volts and I can't hear any leaks, doesn't mean there isn't any :p

I also had the box sort of in the middle of the room but when sitting on the couch, the 30hz tone sounded well for 7 volts, what do you think this cab/driver is capable of safely hitting for voltage? The excursion was very small at that voltage as well, which gives me hope

Also, one thing I wasn't too satisfied with was when playing music tracks, there just wasn't really any bass...

I ordered a Foster plate amp in the mean time because I think that my Pyramid just plain sucks, gain was turned up almost all the way to get 8 volts

That's it for now, feel free to post comments

Re: Table Tuba build!!

Posted: Tue Nov 16, 2010 12:50 am

by Radian

congratulations you built a Hi-fi sub that will now expose every weak link in your signal chain. At a minimum, your going to need a crossover (or an amp with a crossover built in). What's the spec on your pyramid amp? Sounds to me like you need a better input source.

Re: Table Tuba build!!

Posted: Tue Nov 16, 2010 1:55 am

by digital_chris

Well, for now I am using the built in crossover in my AVR to control the freq going to the sub. I thought my amp would have enough power to feed the Dayton driver but maybe not... hmm.

The amp supposedly puts out 1000w x 2 in 4 ohms, who knows what that translates to RMS, either way I figured it would be enough for this driver. But, all I did before firing the cab up was change my mains to small, turn subwoofer on and set freq to 80hz. Is there something I'm missing?

Man, I really hope this thing kicks butt in my LR, I have very high expectations, which in turn could be a problem :p

Re: Table Tuba build!!

Posted: Tue Nov 16, 2010 8:25 am

by Radian

Biggest thing to abide by once the Foster amp arrives is placement. Read the last few pages in the plans. Unless the cab is actually used as a table, you shouldn't be looking down the mouth at all.