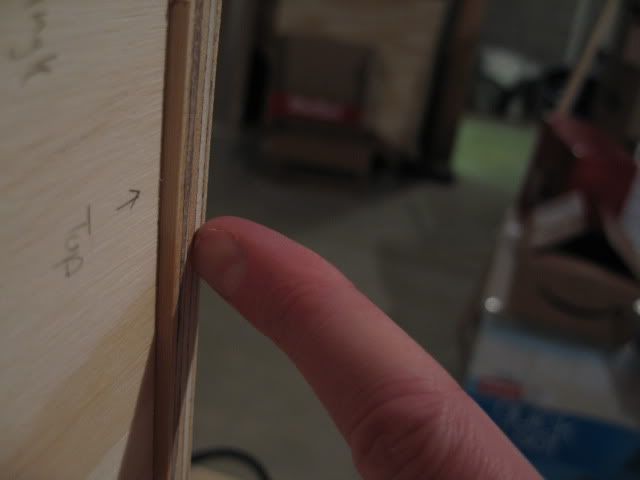

So finally Panel 3 is installed.. This by far has been the panel from hell. All is well now though. I test fit the driver with the socket caps. Fits perfectly and no obstruction from any hurricane nuts.

Also a quick tip I thought I'd share. For slow asses like myself that only use a bit of PL every other day, the way I preserve it is by using a spare Nitrile glove an elastic band. Not sure how everyone else does it but this method seems to work for me.