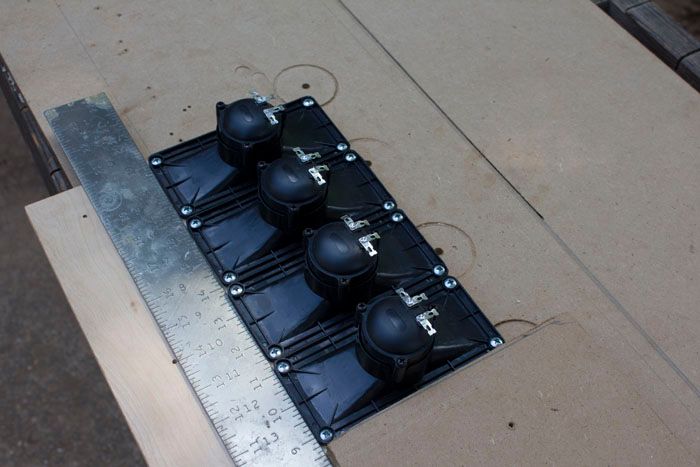

Here is a group photo. I ran out of terminal barrier before I could finish the last one.

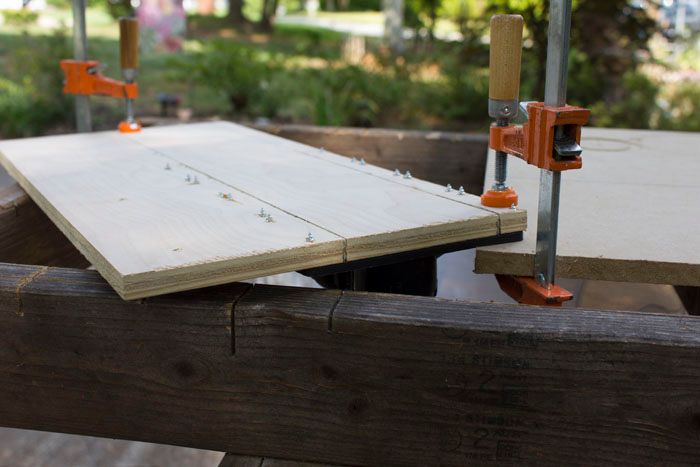

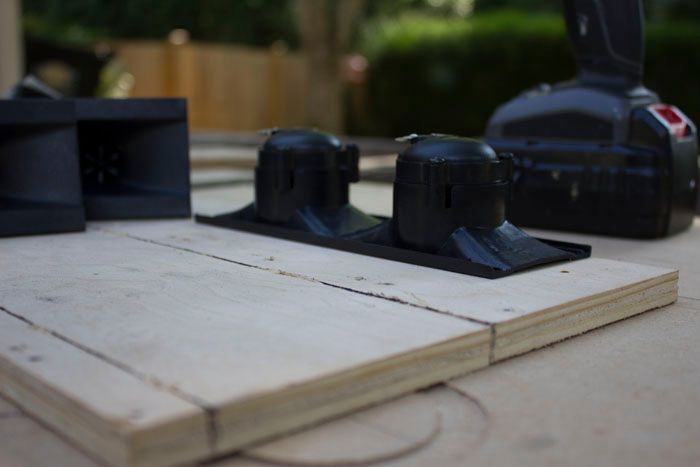

Here is a better shot. Does everything look in order?

Do you have a miter saw? I have cut all my piezo with a miter saw.kenkenni wrote: Anyone got any good tips for cutting

the tweeter array for those of us without a saw table, that will make the task easy. I will figure it out as usual but any good advice helps.

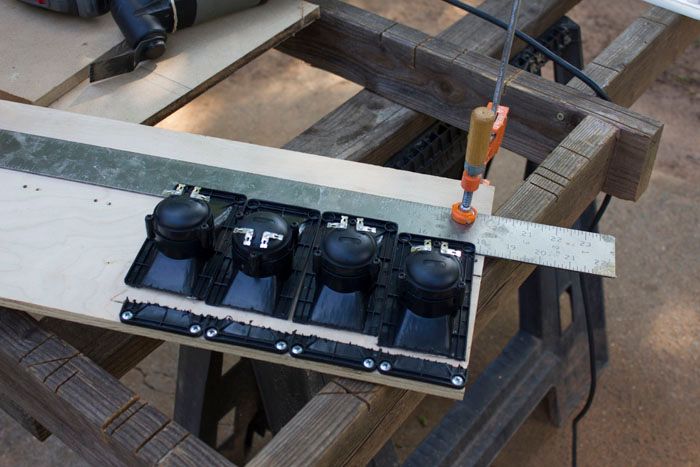

+1, but not with a clamp. Make the sled with a 45 degree cutting edge. Screw a stop board to the underside of the sled to set the distance from the outer edge of the piezos to the cut line, screw all of the piezo horns to the bottom of the sled against the stop board, and cut them all with one pass. Make sure you use a fine tooth plywood blade or an abrasive blade.DJPhatman wrote:Over-width saw sled. Clamp the piezo body, with no element mounted, to the underside of the saw sled

|

|