Wedgehorn 8's w/ horn finishing option

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Wedgehorn 8's w/ horn finishing option

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

O.O it works thanks for the pic sending tips Grant, in photobucket i have to resize the img file in the edit option to get them to fit. Can only fit 700x700 pixels, not the format of my camera atm.

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

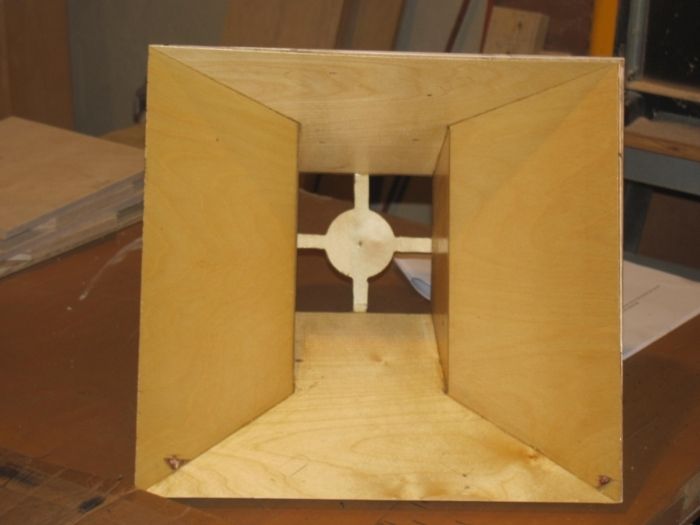

one  wedgehorn assembled another waiting. I'm sure the experienced builders here can see the 3 mistakes made in the lh assembled wh 8

wedgehorn assembled another waiting. I'm sure the experienced builders here can see the 3 mistakes made in the lh assembled wh 8

wedgehorn assembled another waiting. I'm sure the experienced builders here can see the 3 mistakes made in the lh assembled wh 8

wedgehorn assembled another waiting. I'm sure the experienced builders here can see the 3 mistakes made in the lh assembled wh 84x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

The inside of these wh 8's are finished in polyurethane. It is somewhat more trouble in sanding and scraping of excess glue on the inside of the horn required, and requires you to do the (1 coat/light sanding/recoating of the urethane) before installing the tweeter array baffles, then to finish them after installing. The inside(showing) side of the horn has to be scraped with a very sharp chisel and sanded with a detail sander with a pointy sanding disc on a multi cutter tool to remove any glue in there cuz it will show up very dark when the urethane is applied. To counteract the removal of excess glue from the inside of the horn i ran an extra bead of pl on the outside of each one, across every joint. I'm sure many will not want to go through this somewhat more trouble for a finish effect, but I thought it was worth it for this first build, also being a painter/carpenter finish is important to me. Only the inside of the horns will be finished in this way. The outside of the boxes will be finished in duratex as usual, but i thought it was a nice touch to have the player to whom the monitor is pointed to see the urethane finish inside. Also i painted the outside of the horns and inside of the cases a dark grey because i just don't like the sight of the raw blonde wood and glue splatter seen through the ports/handle holes. The very dark grey paint is just a cheapo interior flat brushable house paint.

Last edited by heavybdrums on Sun Jun 07, 2015 9:18 pm, edited 1 time in total.

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

The screw bust-outs in the bottom left and right hand corners will be covered with the grille frame

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

Note the extra beads of glue (pl) on the outside of the horn

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

Yes boys-n-girls those are the plans..right there as the work is being done. Already through several mistakes i have found that you should have the plans right there reading and turning pages as you progress through each and every step of every build, no matter how many you have previously done. The plans are correct, constantly updated and are exactly to be followed to the letter. (assuming my custom finishing options are not a change in the actual build as spec'd).

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

- LelandCrooks

- Posts: 7244

- Joined: Thu May 04, 2006 9:36 am

- Location: Midwest/Kansas/Speaker Nirvana

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

Nice

If it's too loud, you're even older than me! Like me.

http://www.speakerhardware.com

http://www.speakerhardware.com

Re: Wedgehorn 8's w/ horn finishing option

Great job, I am watching this thread as I am finishing up a couple Wedgehorn 6's. Thanks for the build thread.

- heavybdrums

- Posts: 366

- Joined: Fri May 22, 2015 3:46 pm

- Contact:

Re: Wedgehorn 8's w/ horn finishing option

ok..just to list a few mistakes i made on this my first BFM build that may save you from them are: 1) not cutting the horn mouth panels as mirror images, had to re-cut them. I would suggest reviewing the sketch-up drawings after marking and before cutting to make sure they wind up being mirror images in every way. The sketchup is very cool, you can grab and move individual parts around and rotate them to view. 2) Being somewhat impatient i fastened the horn assembly into the outer box before installing the tweeter array vertical braces. Not really a big problem just had to pre drill and drive 6# nails at an angle through them into the horn top and bottom. 3) once the horn assembly is all put together you pass it through the table saw to final cut it to size so it will fit nicely into the outer shell, once again the sketchup will show the orientation of the horn into the body so that you cut the correct size along each edge. I actually cut the horn to the wrong dimensions ( got up and down confused) and had to remake the whole thing over. Happily, now i have a full scale model of the horn at my disposal to view the orientation of all the parts, ok well i got something good out of it. Once the horns are constructed its all down hill from there but extra time spent on them will make the whole thing go easier.Guitbusy wrote:Great job, I am watching this thread as I am finishing up a couple Wedgehorn 6's. Thanks for the build thread.

4x WH8 delta pro

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

2x WH10 Deltalite 2510

4x Dr250 Deltalite II 2510

8X Titan 39 3012lf, 28"

4X Tuba 60 W/ lab 15

FB: https://www.facebook.com/sunsoundservices/ likes appreciated

Re: Wedgehorn 8's w/ horn finishing option

heavybdrums wrote:ok..just to list a few mistakes i made on this my first BFM build that may save you from them are: 1) not cutting the horn mouth panels as mirror images, had to re-cut them. I would suggest reviewing the sketch-up drawings after marking and before cutting to make sure they wind up being mirror images in every way. The sketchup is very cool, you can grab and move individual parts around and rotate them to view. 2) Being somewhat impatient i fastened the horn assembly into the outer box before installing the tweeter array vertical braces. Not really a big problem just had to pre drill and drive 6# nails at an angle through them into the horn top and bottom. 3) once the horn assembly is all put together you pass it through the table saw to final cut it to size so it will fit nicely into the outer shell, once again the sketchup will show the orientation of the horn into the body so that you cut the correct size along each edge. I actually cut the horn to the wrong dimensions ( got up and down confused) and had to remake the whole thing over. Happily, now i have a full scale model of the horn at my disposal to view the orientation of all the parts, ok well i got something good out of it. Once the horns are constructed its all down hill from there but extra time spent on them will make the whole thing go easier.Guitbusy wrote:Great job, I am watching this thread as I am finishing up a couple Wedgehorn 6's. Thanks for the build thread.

-

caddylackn

- Posts: 136

- Joined: Tue Apr 15, 2014 8:24 am

Re: Wedgehorn 8's w/ horn finishing option

Bill's plans are a lesson on both being patient and following directions. If you are not patient in reading and following the directions, it will bite you.

The good news is PL and Duratex will fix and cover up most mistakes

The good news is PL and Duratex will fix and cover up most mistakes

16.5" AT w/ Infinity 860w

TLAHs w/ 9 mids & 16 tweets

17" THTLP w/ Dayton RSS315HF-4

16" TAT w/ Infinity 1060w

18" TT w/ Dayton DCS-205-4

5.5" TrT w/ DCS-205-4

T-18 w/ DCS-205-4

33" THT w/ Dayton Titantic 1200

DR200s

TLAHs w/ 9 mids & 16 tweets

17" THTLP w/ Dayton RSS315HF-4

16" TAT w/ Infinity 1060w

18" TT w/ Dayton DCS-205-4

5.5" TrT w/ DCS-205-4

T-18 w/ DCS-205-4

33" THT w/ Dayton Titantic 1200

DR200s