Using a great online panel cut optimizer, I found that I can get this whole build to fit on 3 sheets of BB after I downsized the T45 to 18" wide. Which brings up a question. According to Bill's plans, panels up to 17" in width require only 1 set of braces. I have heard that panel flex robs performance from Subwoofers so being on the outer limits of a single brace cab, would I be gaining anything from adding an additional set of braces (even if its just to the mouth of the cab) or is the single set plenty for an 18" outside width T45?

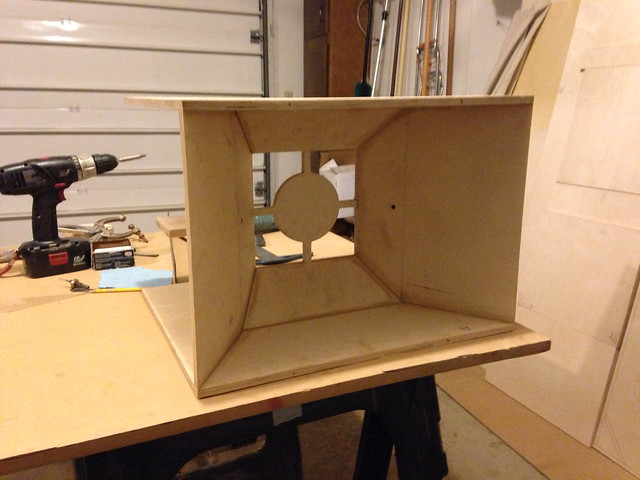

Back to the build:

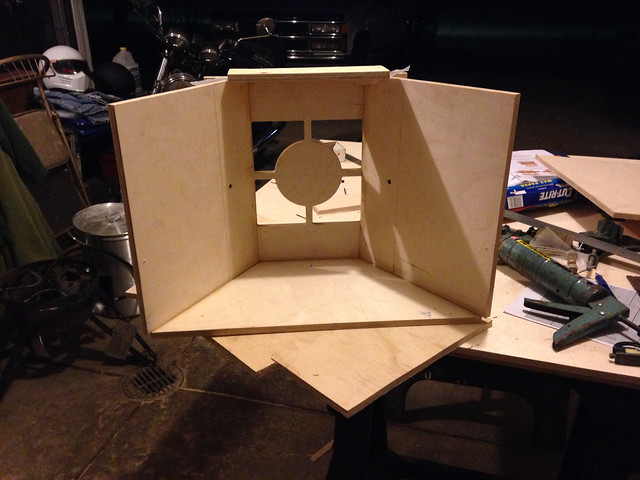

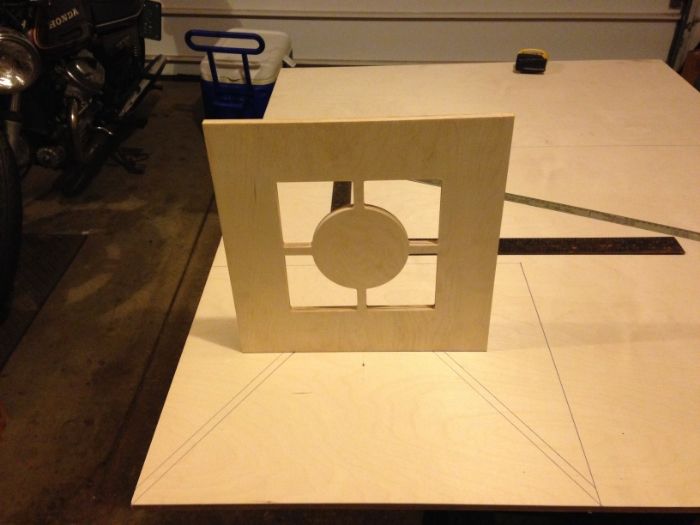

Very happy to have access to a HAAS CNC. It made cutting the OT Baffle a breeze!

Can't Wait to make progress on this big guy!

More updates in the near future. Thanks for looking everyone!