I'm building 4, 24" T48s (23" internal). I went back and forth about how wide to build them. After staring at chart after chart of "this cab vs. this other cab" I determined that the advice I was initally given was the best way to go. 24" T48s are the best compromise b/t performance and portability...if a T48 can be called "portable." The cabs will use the 3015LF driver and be limited in frequency and voltage by a Driverack PA+. They will be powered by a Berry EP4000, which at roughly 5 ohms per channel (2 cabs per channel) should give me roughly 800-ish watts per channel. More than enough for continual visits from Officer Friendly.

Let's start on a serious note. The two most important pieces of equipment for any woodworking are these:

You're only issued one set of eyes, so cover them. While hearing protection might seem superfluous on this forum, the drone of a saw and a vacuum for hours on end leads to hearing fatigue. Which leads to physical and mental fatigue. Which leads to injuries. Once you get used to wearing glasses/muffs, you don't even know they are there.

My "shop" is in my garage. And my garage is in steamy San Antonio. It is HOT in my garage. "How how IS IT in your garage, Mike?" Glad you asked.

It's this hot. Taken today about an hour after I started work:

And during the summer (which is 6 months long down here) my garage is never below 85F. EVER. I drank almost a gallon of water during the 6+ hours I was in there today and did not use the bathroom, not once. Talk about sweating off a few pounds!

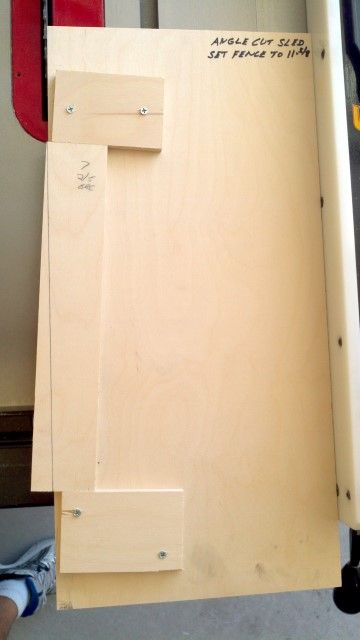

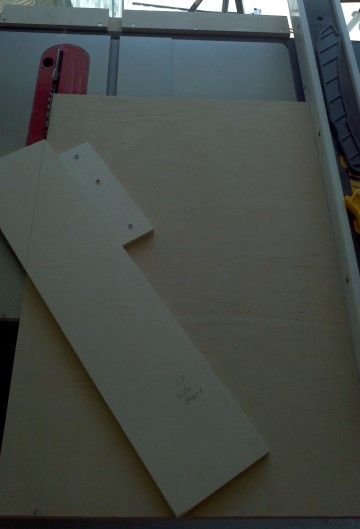

Today was a great day. Not only b/c I got all the panels (including the braces) rough cut, but b/c I discovered that it indeed possible for me to cut 5'x5' plywood on my table saw both accurately and safely. Previously, including earlier today, I was afraid of trying to cut full size sheet goods on my table saw out of fear of injury and jagged cuts...in that order. So I have used circular saw sleds...with horrible results. I build the sled and it's totally straight and accurate but for some reason I can never cut a straight line with it. I build a NEW SLED last night. It was perfectly straight. Clamp it down on my first piece of BB today and run it through and both the panel AND the sled now have a lovely "response curve" line to them. Argh!!! So I was forced to man-up and use the TS. It was not easy, but I was able to manhandle 14 sheets of expensive BB through there with great results. I am quite pleased.

So after 6+ hours of cutting, I wound up with this pile of main cab parts. Notice they are stored flat, particularly with the sides and back on the bottom. If they look small, that table is 8'x4'. The sides are arguably the most important pieces b/c if they are not flat, it could screw everything up. I'm trying to hedge my bets, here.

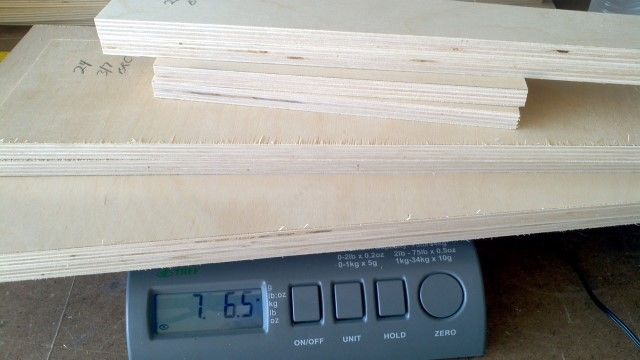

And this pile of braces:

If you're thinking "Pfft! That's just a few parts!" Here are the main cab parts in piles.

Here:

And here:

IN total, I cut ONE HUNDRED FOUR (104) parts on the TS today. I have Cutlists for both the main cab and the braces, but I am hesitant to post them here out of fear of giving away too much info. So I'll err on the side of caution and won't post them. If I get the OK, I will throw them up here. I printed out the "full size" sheet of each supply piece. IOW, when hitting "Print" in Cutlist, I checked all the boxes. As I cut a main piece, I put an "X" over it's identical piece on the Supply Piece page. Being that most pieces are cut as multiples from one larger cut, as I cut each individual piece, I lined it out on the "Parts" page of the printout. When I was done cutting, I measured EVERY piece for accuracy. After verifying it, I colored it with yellow hilighter on the "Parts" page. Anal? Yes. Thorough? You betcha.

I will cut the braces to shape and lighten them up tomorrow. I also am using the one-piece flange trick, so I've got some measuring to do there. Bruce Weldy will help me with that (hopefully, right buddy?

The following info/pics are not directly about the cab, but I thought you might find them interesting. If not, you can stop reading now.

I own a table saw and consider myself lucky to do so. I waited 20 years to have one. When I was younger I had neither the money nor the space for one. I built my car stereo speaker boxes with a jigsaw and a lot of sandpaper. I don't think any of them were truly square. Anyway, cutting wood creates dust (duh). It either goes everywhere or you have a vacuum system of some sort. Whether that be a shop vac or a dust collector, anything is better than nothing. I have the Harbor Freight 2HP dust collector (DC) with a Wynn canister filter on it. I also have a homemade Thein Baffle (Filter) (plans easy to find online) in between the tool and the dust collector.

The Thein acts as a pre-filter, collecting the large dust before it reaches the DC. When built correctly, a Thein can separate as much as 95+% of all airborne particles before reaching the DC. Here is my setup. Thein baffle (AKA garbage can Thein)on the left, DC on the right. All connected with 4" flexible hose.

Here is how much dust ("wood flour" b/c it's so fine) was in the bag after cutting all that wood.

Here's how much was in the garbage can. Bad angle, but the high part of the pile on the right is about 9" deep. The rest around 6". Nuff said here, right?

Here is what the piping/lid part of the baffle looks like. Again, plans are free and online. There is some science/math involved in this, but I just copied verbatim what I found online and it works perfectly. I'd be happy to point you in the right direction if interested.

That's all for today. I will try to make the subsequent posts in this thread a bit shorter. Hope you enjoyed reading.