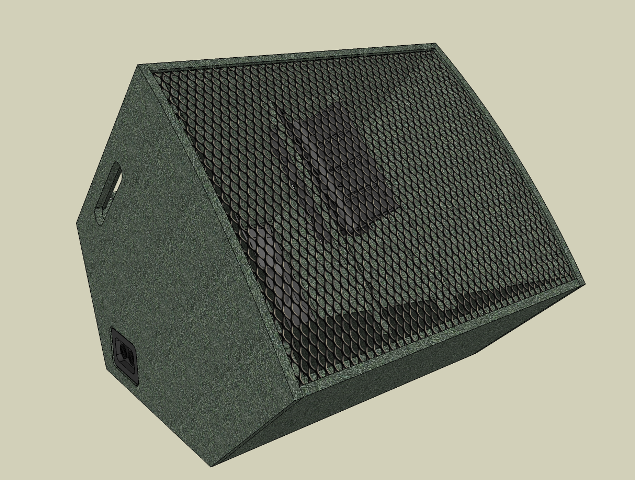

As noted on another thread, I am now building a pair of WH10s that will be fitted with a curved grill.

This is the modified Sketchup model:

Here are some pictures of the build:

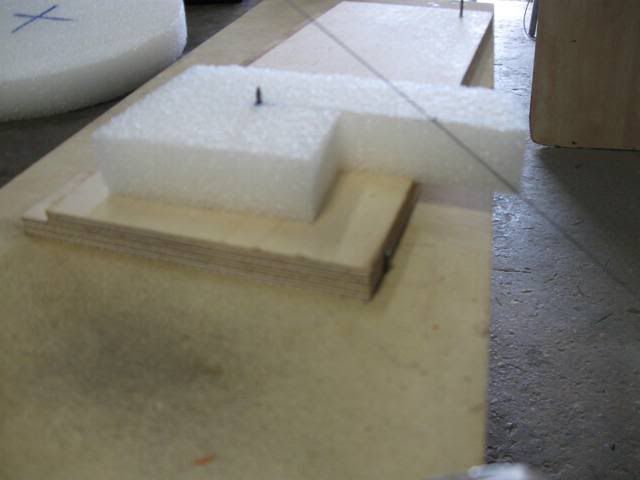

Cutting the baffles and spacer rings:

Cutting out the throat opening:

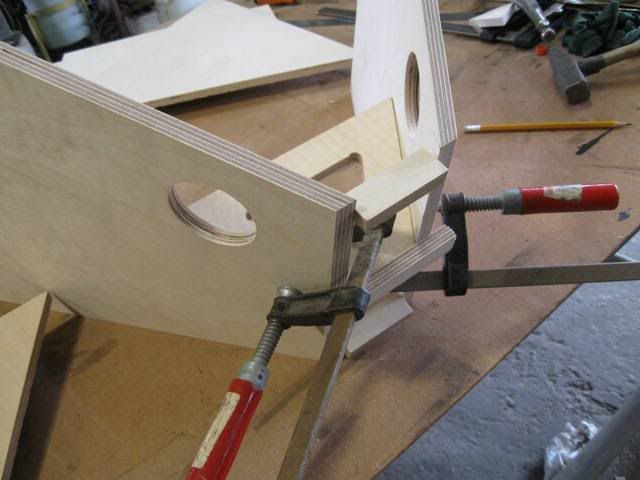

Gluing spacers and baffles:

Baffles ready with t-nuts:

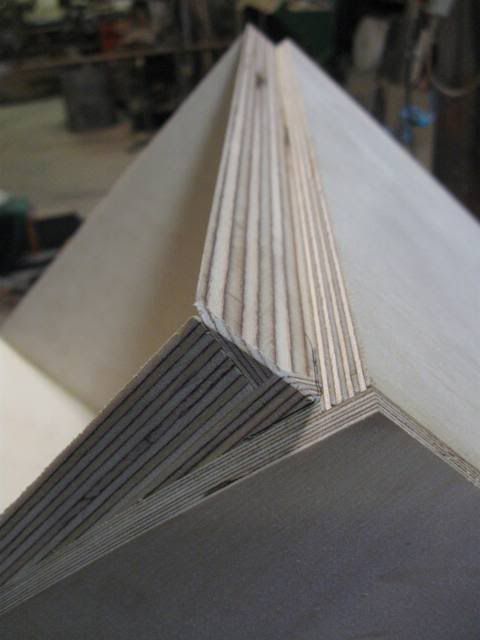

Routed edge of side panel (mod from original plan)

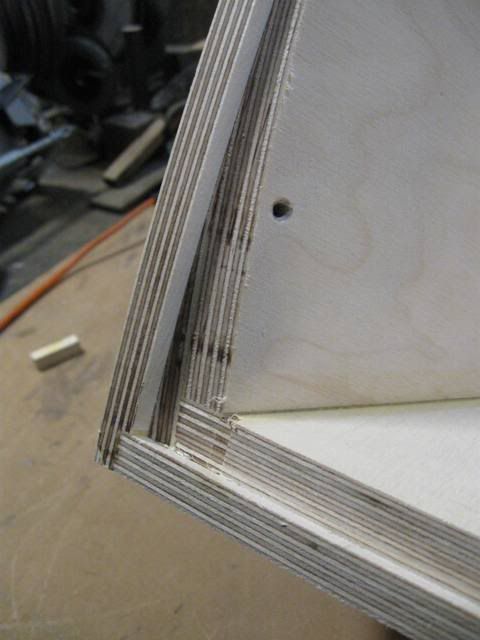

Routed recess for Speakon dish:

Shell panels Ready with braces:

First shell panel attached to side panel:

Second Panel:

Second side panel:

Horn jig in place:

Front edge of horn side panels are aligned for additional thickening strip

(This is another mod/addition to the plan needed because of the curved front - will be clear later...)

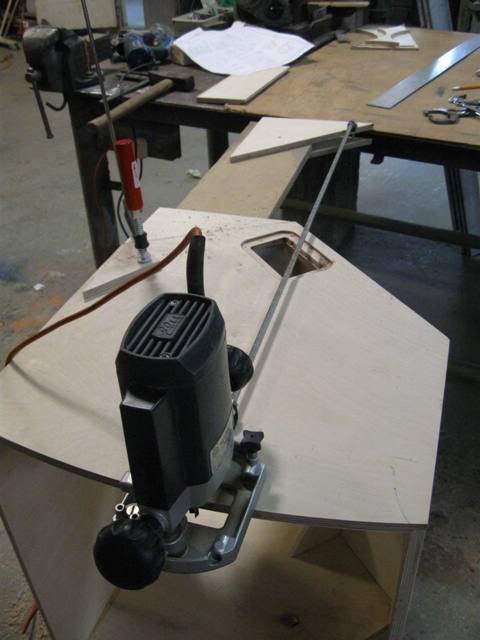

Routing the front edge/curve of the side panels:

Thickening of the dish opening edges:

The outer shell in 'work' position:

Managed so far...: